Shutoff valves are different, from a structural point of view, devices that are used to regulate or completely block the flow of the working medium in the pipeline structure. The medium transported by communication can be of three types: liquid, vapor, gas. These products are mounted on pipelines with different pressure indicators and are used in almost all cases.

Content

The main types of valves

Today, there are many products that belong to one large construction segment - valves. Such devices are used in various fields of human activity; in most cases are indispensable. Shutoff valves can be made of different materials. Consider them:

- cast iron;

- steel;

- copper.

In plastic communications, elements of plastic valves are used. Stop valves are classified according to two main indicators, the first of which is the operational area. Consider the main types of pipe fittings depending on the area of use:

1. Industrial. Such products are used for various purposes in industries, as well as in the national economy. Industrial valves are mass-produced in large volumes for plumbing, communications, transporting steam, heating lines, etc.

2. General industrial. Such shutoff valves are used in non-standard conditions. For example, in communications with high pressure, temperature, at low temperatures, in pipeline structures that transport aggressive chemicals, toxic and radioactive products. This variety of locking products can include:

- resistant to corrosion;

- cryogenic;

- fountain;

- products with heating;

- fittings for bulk media.

3. Special. This variety of locking devices includes products made to order. Its operational features, as a rule, are indicated in the technical regulations.

4. Shipboard. Such shutoff valves are used on river and sea vessels. Products related to marine valves must have a certain weight, resistance to specific conditions of use (for example, vibration).

5. Plumbing. The most common type of shutoff valves, which is used for household purposes. Such devices are installed on various communications and devices that are operated by consumers. Any plumbing for normal use needs such fittings. Otherwise, it will not function.

Note! The production of valves of this type is carried out on an industrial scale at enterprises.

Such reinforcement is characterized by small cross-sectional indicators.Its control is carried out manually in most cases (shutoff valves of sanitary ware), however, there are exceptions: gas fittings (safety valves), pressure regulators.

Varieties of valves according to their purpose

In addition to the operational area, there is another indicator by which all products of this type are classified - purpose. By purpose, the following varieties of valves are distinguished:

- Locking It is used to completely block the flow of the working environment in communication. Such fittings should have good sealing performance and be highly reliable.

- Regulatory. It is used for the controlled regulation of the flow of the working medium within a particular communication. Adjustment is carried out by changing the operating parameters, which include:

- temperature;

- pressure.

- Distribution and mixing. Such reinforcement is used to differentiate the flow of the working medium in different directions or, conversely, to connect the flows together.

- Safety Safety or protective fittings are used to automatically protect communications and various devices from overloads that are caused by high pressure. Such products are able to relieve excess pressure of the working environment.

- Cut-off. Designed to completely shut off the flow of the working medium (regardless of the state of aggregation). Such fittings, in addition to completely cutting off the working medium, can carry out its adjustment.

- Phase separation. Such fittings are used for automatic separation of the working medium. Such reinforcement can include:

- condensate drainage products;

- oil separators.

Ball and plug valves

Such cranes are mounted on communications that transport various media: water, steam, and gas. The main characteristics of these products include small dimensions and small resistance indicators. The weight of such products, depending on the size, can be from 0.8 to 8.6 kg.

To date, the most common are ball and cork valves. According to the sealing option, they are classified into two types:

- tension;

- stuffing box.

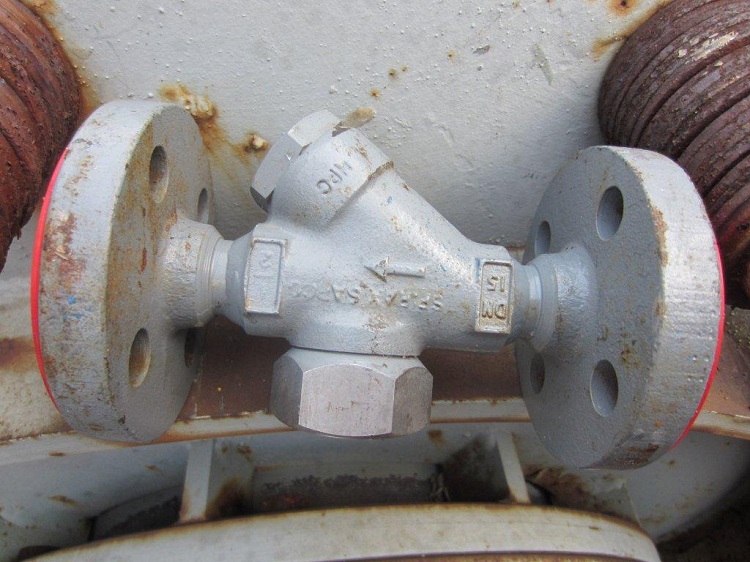

There are three ways to dock such valves with a pipeline:

- by means of a connecting fitting (coupling);

- using a flange;

- using special welding equipment (welded method).

A plug valve (valve) is used, as a rule, for communications that transport natural gas. The operating temperature values for such gas shut-off valves reach +50 ° C. Installation of valves of this type is carried out in any necessary position with the help of couplings. They are mainly made of cast iron and are able to withstand pressure equal to 0.1 MPa (1 atmosphere).

The installation of flanged taps is permitted on pipelines with an operating temperature of −40 to +70 ° C. Cranes are regulated remotely, however, the option of manual control of the product using a special flywheel is possible. Repair of valves of this type is quite simple because during installation you can choose a convenient position that allows you to carry out this event quickly.

Note! Flanged models are mainly made of steel, which has high strength characteristics. Such devices are mounted on the pipeline by means of special elements - flanges (hence the name).

Stuffing box models are made of cast iron and mounted on the pipeline by means of couplings. Such cranes are operated at water and oil pipelines. Temperature indicators at which the gland crane carries out its work can reach +100 ° C. The stuffing box is made of cast iron and is usually filled with rubber or hemp. The permissible pressure of the working medium for such models is 1.0 MPa (10 atmospheres).

As mentioned above, ball models are characterized by low resistance indicators, however, the quality of these products is very high. They are used even in communications, which differ in large cross-sectional indicators. Such valves are made of cast iron, and sealing elements from a special substance - fluoroplastic. The working pressure for such devices is 1.0 MPa, and the operating temperature reaches 100 ° C.

Stop valve

To date, the most common are shut-off valves, which are controlled by a flywheel or, in some cases, an electric actuator. However, there are models that are controlled remotely. Shut-off valves are a very popular fittings for sewer communications. For sewerage, valves of various material are used, including plastic ones. However, cast iron products are most often used.

Such devices are equipped with a special o-ring, which is made of fluoroplastic, rubber material or leather. Cast-iron and plastic valves with electric drive are mounted on pipeline structures transporting water, steam, air, etc. Such a valve is installed on the pipe using couplings.

The temperature of the working medium of valves for sewage is not more than 50 ° C. Products controlled by an electric drive are mounted on communications transporting the working environment at a temperature of +45 ° C. All types of valves (valves and gate valves) in most cases are made of cast iron material and are used for pressure and pressureless sewer communications.

Damper

These products are operated in communications that have cross-sectional values up to 2200 mm. Consider the main advantages of using dampers:

- ease of installation;

- repair of valves of this type is quite simple;

- light weight;

- compactness;

- easy handling;

- affordable price.

Helpful information! In most cases, the dampers are adjusted manually, however, some models are equipped with hydraulic or pneumatic actuators at the factory.

There are damper controlled by electric actuators. Such models are used in communications, the cross-sectional indicators of which vary from 300 to 1600 mm, and the pressure of the working medium is approximately 1.0 MPa.

Pipeline structures that transport water are equipped with special flangeless dampers that can operate at a pressure of 1.0 MPa. Such models are equipped with a rubber sealing ring, through which the necessary sealing performance is achieved. Manually adjustable models are mounted on the pipeline in any position, and remote controlled models are installed with the electric drive up.

In addition to the flanged method of docking this product with communication, there is also a welding method. These devices are made of cast iron or steel.

Gate valves

Gate valves differ in small length and are used, as a rule, on the main pipelines, technological communications. These devices are equipped with a special structural element - the spindle.

The spindle can be of two types:

- retractable;

- non-retractable.

Installation of such devices on the pipeline structure is carried out by means of flanges. The material from which the valves are made can be different, however, cast iron products are most common. These devices are operated in communications transporting:

- fuel gas;

- coke oven gas;

- oil and oil.

In the first case, valves are used that can withstand the temperature of the working medium up to 100 ° C. Such gate valves are wedge-shaped double-disc and are equipped with a non-rising spindle. The pressure indicator at which these products are capable of functioning is 0.6 MPa (6 atmospheres). These items are manually adjusted.

Gate valves mounted on pipeline structures that transport coke oven gas are distinguished by a retractable spindle. Adjustment of such devices is carried out by means of an electric drive. Products with a cross section of 1300 mm are capable of withstanding a pressure of 1.8 MPa at a temperature of 200 ° C. And parts with a cross-sectional index of 1500 mm withstand a pressure of 0.05 MPa at an ambient temperature of 85 ° C.

For communications that transport oil or oil, steel valves are used. The spindle in such devices is extendable, they also have special nozzles. The temperature resistance of such valves is quite high - they are able to function at a temperature of the working medium up to 250 ° C.