Regardless of the type, any heating system must be set up. Various methods have been developed for this. All of them are designed to maximally approximate the operating parameters of the network to the calculated ones and thus increase the efficiency of its functioning. Adjustment is carried out using a variety of special tools. However, the most accurate adjustment is achieved by using a balancing valve for the heating system.

By means of a balancing valve, it is possible to achieve optimal flow rate and temperature in radiators

Content [Hide]

Principle of operation. Views

Briefly, the principle of operation of this device is formulated as follows: it changes the flow rate of the coolant by reducing or increasing the bore, while simultaneously changing the hydraulic resistance in a certain section of the heating system.

The balancing valve is available in two versions, each of which is applicable to heating networks from any type of pipe - metal, plastic.

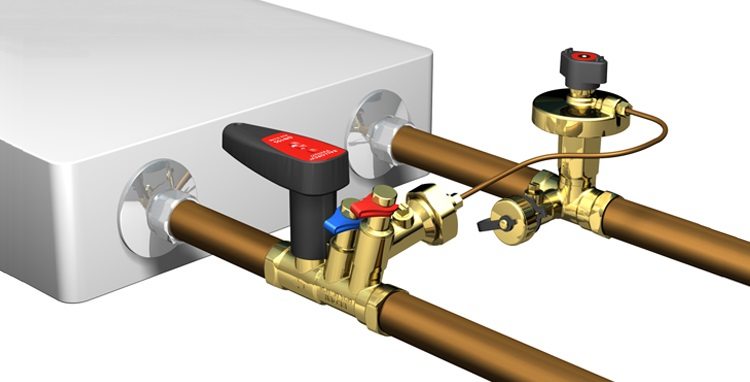

Auto. This type of balancing valve, depending on the level of coolant flow rate and pressure difference, allows you to flexibly and quickly change the settings of the heat supply line. It is used in conjunction with a shut-off valve, which is installed in the pipe supplying the working medium. The device itself is mounted on the return pipe. It is he who is responsible for the pressure drops present in the heat supply branch. It should be noted that such a balance valve for heating provides an opportunity to divide the network into separate zones, taking into account the scatter of the values of this parameter, and to start them in turn.

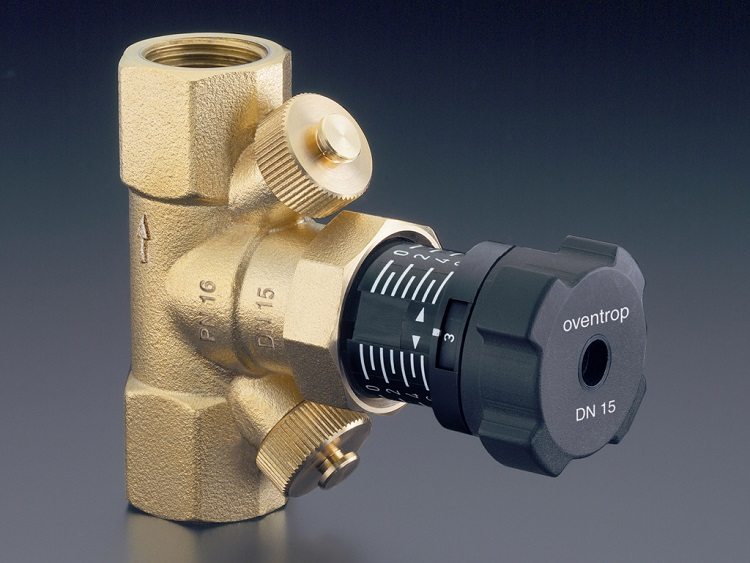

Manual. The design of this modification of the balancing valve of the heating system consists of a bronze or brass body, in which there are an adjustment mechanism and nipples. The latter are used to connect instrumentation. The adjusting mechanism of the heating valve consists of a rod, as well as a plastic handle on which a measuring scale is applied. In general, devices of this type provide the ability to configure the heating system at constant pressure. With their help, hydraulic balancing can be carried out by turning off individual segments of the heating pipeline with their subsequent emptying through a special valve.

Two more types of devices are also classified as balancing valves.

Thermostatic valve. Such a detail provides:

- balanced temperature conditions in the room. Its functions include creating a comfortable microclimate in housing and maintaining it at a stable level;

- increase the profitability of the heating system;

- energy saving.

The principle of operation is to monitor the temperature of the living space. If it exceeds the upper allowable limit, the thermostatic valve will block the flow of coolant to the radiators. When the temperature reaches the lower level, the flow of the working medium will be resumed.

Automatic flow stabilizer. Such a balancing device, in accordance with its name, maintains the flow rate of the coolant in the risers of exclusively single-pipe heating systems.

Good to know! There is another area of its application. With the help of this part, the heat supply line is blocked with the aim of emptying it from water for the subsequent measurement of the actual coolant flow.

Characteristics and properties

The main parameters of the heating control valve of all the above types are similar to the characteristics of other elements of the pipeline. Such devices are made mainly of bronze and brass. However, there are samples on the market made from galvanized steel. Nevertheless, the main share of this segment of the world market (up to 90%) is occupied by brass valves. This is due to their greater reliability and durability compared to other analogues.

The scatter in the values of the angular diameter is very large. This indicator ranges from 15 ≤ Dat ≤150 mm. It all depends on the manufacturer. The larger it is, the wider the range of its products. For example, Danfoss produces models with unique sizes and a wide variety of designs. This is especially true for the MSV-BD and MSV ranges.

In terms of nominal pressure, the situation is as follows: most manufacturers seek to supply Cimberio valves to the market that can withstand at least 20 bar. The operating temperature of such products ranges from -20 ≤ T ≤ +200ºWITH.

Of the main advantages of the balancing valve for heating systems can be identified:

- fine adjustment of temperature or pressure level;

- simplification of work related to the configuration of the structure;

- relative simplicity;

- durability;

- reliability;

- reasonable cost.

The disadvantages of such products are practically absent. Moreover, in domestic use there is no alternative to balancing valves. Without installing them, you will be forced to regularly call plumbing and perform laborious manipulations with the heating system, which is unlikely to please you.

Valve mounting

Installation of this device should be made only in two cases:

- when constructing a new structure, the presence of balancing fittings in which is provided for by the project;

- when there are problems with the distribution of heat on certain branches of the heating system.

Mount the fittings in such a way that after it there remains a free part of the pipeline with a length of not less than two pipe diameters

When installing the valve, it is necessary to follow the rules for working with pipelines, but taking into account the following nuances:

- to the balance valve there should be a straight pipe section with a length of 5 diameters, and behind it - at 2. This will exclude coolant turbulence;

- when cutting fittings into pipes, it is imperative to observe the flow direction. It is indicated on the case of each device. This rule is also relevant when replacing a valve;

- ingress of dirt and any foreign objects is unacceptable;

- if an automatic model is used, it is necessary to provide for the presence of an additional fitting in the immediate vicinity of it. With the valve closed, it will ensure complete filling of the circuit.

Good to know! As practice shows, installation of the control valve and professional balancing of the heating system saves almost a third of the heat. At the same time, the cost of the work of even experienced heating engineers, who, in fact, should be charged with their implementation, is quite accessible to the wallet of our average compatriot.

The automatic balance valve is set up using the flow and differential pressure tables, as well as the flow meter. But the initial calculation is important to perform at the design stage of the heating system.

Model Overview

These products are presented on the modern market with a sufficiently large number of samples. However, only those that have successfully passed the test of time deserve special attention.

In order for the valve to function smoothly and serve for a long time, you should choose products from well-known companies

These include:

- SRV AG WATTFLOW (manufacturer - company WATTS, Germany). This is a flanged balancing valve with the ability to fine-tune due to the equipment with a flow meter. The presence of an impact-resistant scale allows you to configure the heating system without additional calculations and refuse to use graphs or schemes.

- STAD (international company TA HYDRONICS). Flawlessly fulfills its functions in secondary heating circuits. This balance valve is virtually fail-safe and features a robust design.

- HYCOCON VTZ (OVENTROP company, Germany). Included in the group of manual regulators. Differs in small price and high quality of assembly of separate knots.

- CIMBERIO 727 (GIACOMO CIMBERIO company from Italy). This device provides optimal flow distribution in local systems and domestic pipelines.

- BALLOREX VENTURI DRV (manufacturer BROEN, Denmark). It copes not only with setting the level of the environment, but also cuts it off with just one movement of the handle. In fact, it is a combined version of valves and regulators.

- MSV BD (DANFOSS A / S, Denmark). An analogue of the previous sample. However, according to the parameter the diameter of the angular passage, its lineup includes much more models.

- STREMAX (company HERZ, Germany). Representative of the German range of regulators. Despite the simple scheme, it performs its functions in full. The price of such a device is not one dozen percent lower than the cost of analogues from other manufacturers.

There are other noteworthy samples of even the most sophisticated consumers. But the above is quite enough for the right choice of the balancing valve of the heating system.