The radiators that have served for a long period need to be revised. If repairs were made, it is quite realistic that the appearance of the structure needs to be slightly refreshed, that is, painted. To do this, you need to know the painting area of cast-iron radiators. High-quality heat-resistant paint is not cheap, therefore, having calculated its consumption, it is easier to save on repairs.

Content

Why do the calculations for paint costs for radiators vary?

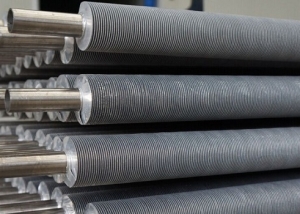

Not everyone wants to get rid of old cast-iron batteries after modernizing the apartment. They are practical and reliable, and if the heating system is cleaned and replaced with rusty pipes, the old radiators after painting will last no less than a decade.

Advice! Do not cover the yellowed, sometimes crumbled and cracked paint layers with a new coating. Do this only after removing the old layers of paint and opening the metal with a primer.

Calculations on paint consumption are complicated by the variety of models of heating devices, differing in many parameters:

- mass (weight);

- aesthetics (design);

- format (dimensions of the section and the entire battery);

- power (heat transfer);

- heat carrier volume (water);

- connection method (lateral, lower, diagonal), etc.

New models are also produced that imitate old cast-iron “accordions”. They exactly mimic the overall structure of classic heating equipment. They have an improved design with artistic molding or designer soldering and comfortable legs from the bottom for floor standing. They require a little more paint and primer, materials must be taken with a margin.

How to independently calculate the coverage area and paint consumption

There are various methods for calculating the painting area of cast-iron radiators, but it is useless to “reinvent the wheel”.

Attention! Manufacturers of thermal equipment reflect this information in the technical description for the model. This value is usually indicated as “heating area”, other options and translations are possible if these are imported models.

Calculating the painting area of the cast iron radiator MS-140 as a classic sample, we take into account the area of one section or “accordion rib”. It is approximately 0.244 m2. A more modern or modified section with a slightly larger center distance (300 mm) has a staining area of the order of 0.208 m2.

Models of cast-iron batteries can vary greatly, so for calculations we take from the documentation (product passport) the heating area of one section. Next, we multiply by the total area of all the ribs with a small margin (adapters, cranes, couplings, legs). For example, in the standard MS-140-500 10 ribs, we multiply by 10 the section area of 0.244 sq.m. We get 2.44 m2. Round up to 3 m.2 - to all adjacent parts. Next, we decide how many layers will be painted.

Innovative methods for determining the area of painting of cast-iron radiators - special computer programs and calculators. They enter the following parameters:

- radiator marking (according to technical documentation).

- number of sections, their length and height.

On the extradition we have a real area of coloring. After receiving the information, a “reset” is entered to clear the window and enter new data.

How to clean cast iron batteries before painting

High-quality painting involves:

- preliminary cleaning of dust, rust and dirt;

- removal of all layers of the old oil;

- primer coating on metal, preferably heat-resistant;

- painting in 2 layers gives the most high-quality and even surface (one layer can be slightly diluted with a solvent to save composition).

Many actions are easy to carry out with improvised means, including brushes for cleaning and washing. Old paint is removed by different methods (can be comprehensive):

- chemical;

- mechanical (special nozzles on the grinder and universal tool);

- thermal (building hair dryer, blowtorch);

- in a manual way.

Advice! With a metal brush, clean the surface before applying the primer to remove unstable particles, which can then stick to the brush or roller.

Not every paint is suitable for painting cast-iron radiators. Only non-toxic heat-resistant enamels for indoor use. They are sold in different forms - spray cans, cans, buckets. If painted without a primer, it is possible to degrease with a solvent that is suitable for the chemical composition. Even if the manufacturer writes about the “harmlessness” and “environmental friendliness” of enamel, when painting the area of the cast iron radiator MC-140 (another model), they use:

- respirator,

- work gloves;

- work clothes and shoes.

It is recommended to ventilate the room at each stage of processing, especially after the paint has set a little. All calculation data are adjusted for any modern model or old model. The area of the heated surface varies slightly with 1K60P-60h500 Berelef, Standard-90, RD-90s, 2K60P-300, BZ-140 × 300, MR-2KP140 Bekard and others. How to calculate the number of sections , on a "calculator" or through a program, decide for yourself. There will be no big discrepancies.