Today, there are many different materials that can be used for chimneys. One option is to install asbestos-cement channels. Such chimneys are easy to install, but the characteristics of the pipes impose certain restrictions on their applicability. Asbestos pipe is mainly intended for water supply, irrigation, ventilation system.

The properties of asbestos-cement pipes allow their use only in those systems where the temperature of the smoke is low

Content

Features of using asbestos channels

Asbestos as a material has a fibrous structure and plays a reinforcing role in pipes. It provides strength to the product. Before use, the asbestos fiber is fluffed, and then mixed with cement and water. The main technological processes for the production of pipes are:

- Formation.

- Hardening.

Formation takes place on the production line. After exposure to air and the acquisition of strength products, they are placed in warm water. The material is applied in layers on the forming drum.

It is interesting! Asbestos fiber can withstand longitudinal stress like some steel grades.

Asbestos pipes are pressure-resistant, withstanding pressure of 6-9 atm. and non-pressure. Their diameters range from 10 to 50 cm, it is also possible to produce pipes with a cross section of 1 m.

Fire safety plays a decisive role when installing chimneys. In this regard, it should be borne in mind that an asbestos-cement pipe is capable of performing its functions at temperatures no higher than 280-300 ° C. This may be the upper part of the chimney where the exhaust gases are almost cooled. Such pipes are applicable only for gas heaters with low power.

Installation of pipes made of asbestos cement in chimney systems

The basic rules for installing an asbestos chimney are:

- preliminary inspection of the product for cracks and chips;

- the cross section of the pipe of the heater must be less than the cross-sectional area of the pipe;

- termination of all joints to a depth of 3 cm with an asbestos cord.

A reinforced concrete slab having a square shape is placed under the asbestos-cement pipe for the chimney. It can be monolithic or consisting of halves. The area of the chimney duct must absolutely correspond to the area of the hole in it. The plate at the edges is equipped with sides of the required height. After that, the space between them and the asbestos pipe for the chimney is filled with slag concrete, sand or brick.

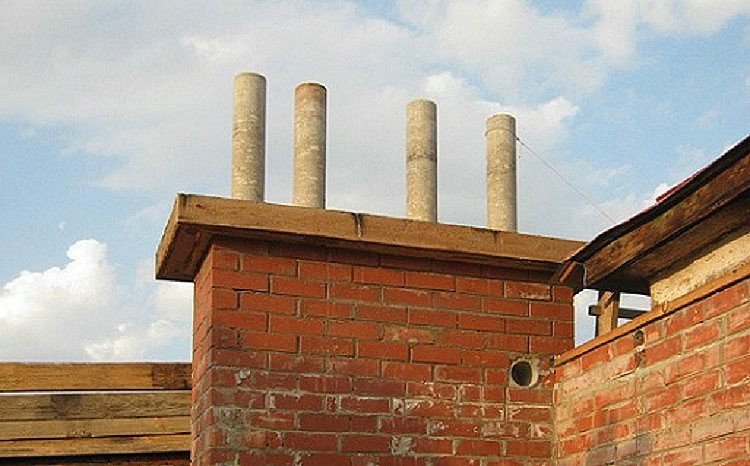

The channel is mounted in the attic. Otter - the expansion of the pipe over the roof, which protects against atmospheric precipitation, can be made round or square, monolithic or precast. If you install a prefabricated otter, then after fixing it is smeared at the joints with cement mortar.

Due to its low resistance to high temperatures, asbestos pipes can only be installed in the upper part of the chimney

To ensure reliable fastening and prevent slipping down under the otter, a cement sleeve is formed. You can also cover the top chimney hood.

Subtleties and installation features

A sufficiently large number of operational shortcomings and installation requirements limit the possibility of using asbestos-cement pipes for chimneys. Is it possible to eliminate shortcomings in work and reduce the risk of fire, depends on the design techniques of flue systems and the use of modern auxiliary materials.

Asbestos chimney pipes burst at high temperatures. For this reason, they are not used in the initial sections of the gas outlet, where the temperature is maximum. Installation of pipes in a shaft that removes the products of combustion of solid fuel appliances is not permissible.

Note! The combustion temperature of coal and wood is much higher than natural gas, so it is forbidden to equip coal-fired units with chimneys made of asbestos-cement pipes.

Asbestos flues are porous and absorb condensate. This quickly leads to their destruction. Therefore, such pipes should be well insulated when discharged through the attic and roof.

Insulation of asbestos-cement pipes for the chimney

Since asbestos is a porous material, soot deposits quickly accumulate on the inner walls of chimney flues. Temperature differences lead to the appearance of condensate, which, together with soot, leads to the destruction of the chimney.

To prevent such consequences, pipe insulation helps. The simplest and cheapest way is to use roll materials. Equally important is the provision of waterproofing. For this purpose, the most suitable is the use of foamed foil polyethylene, which is fixed using wire or metal staples.

Heat-resistant heaters are installed outside. Additional brickwork helps to increase the efficiency of thermal insulation. You can install a metal casing. He puts on an asbestos-cement pipe, which is insulated with mineral wool. To do this, you must:

- from stainless steel (approximately 2 mm thick) make an external thermowell with a diameter 10 cm larger than the pipe;

- place insulating material between the channel and the sleeve;

- provide good insulation of the joints.

Thermal insulation is also arranged with special cinder blocks. They make a box around the channel at a distance of 5-10 cm. The resulting space can be filled with slag, mineral wool or expanded clay.

The disadvantages of asbestos pipes

Manufacturers of asbestos-cement products indicate that they can be used to equip a chimney, ventilation, duct, gas duct. Moreover, the long-term use of such chimney ducts revealed their disadvantages:

- a high probability of bursting or exploding at temperatures above 300 ° C;

- fire hazard due to the high probability of cracking and gas escape;

- a significant reduction in traction due to the lack of supporting heat capacity;

- condensation and moisture absorption;

- the impossibility of installing revision hatches;

- pipe installation only vertically;

- the inability to clean the channel of soot.

Note! It is advisable to install asbestos pipes as interfloor protective sleeves during the installation of the chimney.

Thus, asbestos-cement pipes can be used as chimneys only for low-power heating appliances and only under certain conditions. For high-performance heating appliances that consume solid fuels, it is better to use channels from other materials.