Sandwich pipes are modern products that are used to organize chimney channels. Chimneys made of such structural elements are reliable and functional, and also have aesthetic appeal. The use of these products avoids the installation of insulating material, since they include an insulator layer.

To work with sandwich pipes, you don’t need any special skills, but the organization of the exit of such a chimney to the roof requires compliance with some rules

Content

- 1 Chimney Sandwich Device

- 2 What materials are sandwich pipes made of?

- 3 Methods for joining a sandwich pipe

- 4 By smoke or condensation?

- 5 Diameter selection

- 6 How to determine the height of the pipe above the roof?

- 7 Chimney sandwich wiring through the ceiling

- 8 Installation of a chimney made of sandwich pipes through the roof

Chimney Sandwich Device

Today, such pipes are the most popular for organizing chimneys for private houses and baths. A sandwich pipe consists of three main layers:

- inner contour made of metal;

- an intermediate layer of a heat insulator, which may have a different width depending on operating conditions;

- outer metal circuit.

The heat-insulating layer of the sandwich of the product is usually represented by basalt materials. In addition to the main structural elements, the sandwich chimneys include auxiliary parts. Consider the elements of the smoke exhaust sandwich:

- special fasteners - brackets;

- revisions;

- clamps (crimp type);

- ceiling-boring nodes (PPU);

- tees;

- corners;

- rosettes;

- unloading platforms;

- rats;

- okapniki.

Sandwich construction, taking into account all installation rules, allows for efficient removal of combustion products. Consider the main advantages of sandwich structures that allow them to be so effective in their field:

- the internal circuit, as a rule, is made of heat-resistant material (stainless steel), therefore it is able to withstand high temperature indicators;

- sandwich pipes have anticorrosive properties, so it is able to withstand the effects of condensate, which is formed in the channel due to temperature differences;

- the intermediate layer of basalt insulation reliably protects the outer galvanized pipe from overheating;

- the design of such products protects the insulation from moisture;

- sandwich channels are able to provide normal traction in the system.

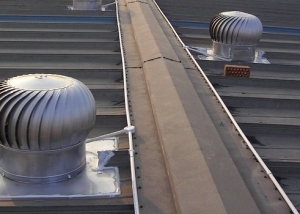

The end of the smoke channel, as a rule, goes to the roof and can be equipped with the following structural elements:

- fungus. A necessary structural element that performs a protective function, protecting the channel from debris, and also due to the aerodynamic design provides air intake;

- spark arrester. A device that is necessary to catch sparks escaping along with smoke from a channel. The spark arrester protects the roof, mounted from combustible materials, as well as nearby buildings with plantings from sudden ignition;

- vane.A device that measures the direction of the wind and also serves as a decorative element on the roof.

Helpful information! Experts recommend choosing a place to lay a sandwich channel closer to the center of a residential building. This is necessary in order to reduce heat loss.

The structure of the chimney sandwich allows you to lay it not only inside the house, but also to bring the channel through the wall, so that most of it is located on the street. However, the most effective option for installing such a chimney is an intra-house.

What materials are sandwich pipes made of?

Today, the structural elements of the chimney sandwich are made of two types of steel:

- stainless steel;

- galvanizing.

As a rule, the inner pipe is made of stainless steel, which is more heat-resistant and has high anti-corrosion properties, and the outer one is made of galvanized sheet. Such pipes are considered more economical than products in which both circuits are stainless steel, so the demand for them remains quite high. On the construction market you can find sandwiches represented only by galvanized steel, however, such products are used only for low-power gas boilers.

The inner pipe is always made of heat-resistant steel, and the outer one can be either stainless or galvanized

Chimneys for high-power heating equipment are made exclusively from stainless steel. Moreover, for such purposes, special heat-resistant steel grades are selected. All well-known steel grades are presented in the table below.

Table 1

| steel grade | Characteristics |

| AISI 304 | This brand of stainless steel is a budget option AISI 316 and is used for low-power and medium-power gas-fired boilers. |

| AISI 316 | A common brand of stainless steel, which includes various alloying compounds (nickel, molybdenum). Pipes made of such an alloy are distinguished by high strength characteristics, good heat resistance and resistance to active chemical compounds. Used for gas boilers of almost any type. |

| AISI 430 | Of the stainless steel of this brand, as a rule, external casings for chimney channels are made. This is due to the fact that the AISI 430 is characterized by low heat resistance. |

| AISI 439 | This brand of stainless steel includes a titanium element, which allows it to be very strong and reliable. Other positive characteristics of this brand of stainless steel include: increased heat resistance and anti-corrosion properties. Chimneys made of this material are excellent for gas boilers, as well as for heating equipment operating on solid fuel, with a capacity of not more than 30 kW. |

| AISI 316I, AISI 321 | Chimneys made of such a material are suitable for any heating equipment operating on solid fuel. The maximum operating temperature for such steel grades reaches +850 ° C. |

| AISI 310S | Pipes made of this steel grade have the highest heat resistance and are used to make a pipe in a bathhouse. The maximum operating temperature for such pipes can reach +1000 ° C. |

The wall thickness of the sandwich pipe can also vary from 0.5 to 1 mm, depending on the operational area. The width of the heat-insulating layer located between the two circuits ranges from 3 to 10 cm.

Methods for joining a sandwich pipe

There are two main ways of joining the individual elements of a sandwich pipe together. Consider them:

- bell-shaped;

- docking of corrugated edges;

- castle connection.

The assembly of the chimney pipe is carried out in segments that are fastened together in different ways, the simplest and most reliable of which is the castle

In the first case, a wider chamfer is present at one end of the sandwich part.Installation of a chimney made of sandwich pipes by means of a bell-shaped connection of its individual elements is the most common. The main advantage of this docking option is the high leakproofness of the channel. Experts recommend purchasing pipes for such a connection if a chimney is laid for gas-fired heating equipment. Of the minuses of such a docking, it can be noted that it requires high accuracy.

In turn, the joining of individual elements of the chimney construction through corrugated edges is a simpler measure, however, it requires a large amount of sealant to ensure the tightness of the channel. This method is suitable if you decide to install the chimney yourself.

The lock allows you to quickly, reliably and tightly connect the chimney parts without using tools.

Sandwich products have a longitudinal seam, which can be of two types:

- welded;

- seam.

Pipes with a weld are used in the case of a chimney made of sandwich pipes for a boiler that operates on solid fuel. Products with a seam seam are used in other cases.

By smoke or condensation?

As mentioned above, one end of the sandwich is wider in comparison with the second, and due to this difference, the pipes are joined. In the case when the end of the pipe with the extended chamfer is up, this installation of the chimney is called "condensate". This is due to the fact that with this arrangement of sandwiches, moisture that condenses on the inner walls of the pipes flows down. This method of connection has its drawbacks, namely: there is a possibility that smoke will leak through insufficiently sealed slots. The installation of the chimney in condensate, as a rule, is used when removing the channel through the wall, since this method requires effective removal of condensate and is not afraid that smoke will leak through the micro-slots.

Note! To organize reliable joints of sandwich pipes, experts recommend using not only heat-resistant sealing compounds, but also tighten joints at the joints with clamps.

The second method is called "smoke" and involves installing a sandwich pipe with the narrow side up. Thus, the subsequent pipe is worn wide side on the narrow end of the previous part. With this installation of the chimney structure, there is a risk of condensate leakage, however, there is no need to worry if all the pipe joints are well sealed. Assembling a chimney through smoke is ideal for organizing an intra-house canal that will go to the roof.

Diameter selection

The choice of the cross-sectional index of the chimney design is a serious event, in which it is worth considering several important rules. The first of them sounds like this: the indicator of the cross section of the chimney should be the same (or greater) than the diameter of the outlet pipe of the heating device. For example, if the diameter of the outlet pipe of the boiler is 100 mm, then the cross section of the flue duct should be the same or greater. It is important to remember that this rule applies not only to the first segment of the channel, but to all the others.

The chimney can be wider than the outlet of the heating device, however, in this case you will have to purchase a special transition element. The transition element is mounted on the boiler outlet and organizes the transition between it and the chimney pipe.

In addition, the choice of the cross-sectional index of the smoke exhaust structure depends on the capacity of the boiler. Thus, you can choose the diameter of the channel before purchasing heating equipment.

Consider the dependence of the indicator of the cross section of the chimney on the power of the heating device:

- with a boiler power of up to 3.5 kW, the index of the cross section of the inner contour of the sandwich should be about 80 millimeters;

- if the power of the heating device is in the range from 3.5 to 5.2 kW, then the cross-sectional index of the inner circuit should not be lower than 95 millimeters;

- when the power rating of the heating device exceeds 5.2 kW, the cross-sectional index of the inner pipe must be at least 110 millimeters.

In any case, it is recommended to do everything in order, so it is better to first purchase a boiler, and only then choose pipes to organize a channel that will exhaust combustion products.

How to determine the height of the pipe above the roof?

First of all, the height of the chimney above the roof depends on where in the house it was made. Consider the basic rules by which the height of the chimney sandwich above the roof is determined:

- the total length of the structure should be 5 m. Deviation from this figure is allowed only to a smaller side, and only when this length does not reduce the traction index in the system;

- if the roof is a flat pipe height according to the established standard should be 0.5 m;

- if the distance from the roof ridge to the chimney sandwich is 1.5 m, then the height of the pipe will be 0.5 m. And if it is more than 3 m, then the sandwich pipe is allowed to be placed below the ridge. However, in such a situation, the location of the sandwich is calculated as follows: the pipe should not be lower than an imaginary line drawn at an angle of 10 ° from the ridge to the horizon.

Helpful information! If for some reason it is not possible to organize a chimney sandwich at the required height above the roof, special devices are used - smoke exhausters. Such chimney devices make it possible to provide the necessary draft by force.

Compliance with the above rules will allow you to set the chimney sandwich at the right height and provide good traction in the system. Thus, the removal of combustion products will be effective regardless of weather conditions.

Chimney sandwich wiring through the ceiling

When installing a chimney communication, consisting of a sandwich pipe, through the roof, it is necessary to take into account the location of the floor beams, and also take into account the roof rafter system. The determination of the point at which the pipe will pass is carried out between these structural components of the building.

The minimum distance from the external contour of the sandwich pipe to the combustible materials located in the house must be at least 130 mm (if the combustible material is protected by a heat insulator). As a rule, to comply with this rule, you often have to resort to the use of forty-five degree angles.

The first segment of the chimney sandwich must be made of a material that is able to withstand maximum temperatures. This is due to the fact that the first pipe is in direct contact with the boiler outlet. Next, the adapter is mounted on the sandwich and only then does the laying of the sandwich pipe begin.

How to make a hole in the ceiling and organize PPU? Consider this process in stages:

- First of all, the place in which the chimney communication from the sandwich pipes will take place is determined. The point of passage of the pipe should be between the beams and should take into account the location of the rafter system.

- Installation of a sandwich pipe through the ceiling is carried out in accordance with all necessary building codes, as well as fire safety rules. After determining the place where the sandwich pipe will be held, it is necessary to start organizing the hole by performing preliminary marking.

- After the hole is ready, you need to secure its edges in accordance with fire regulations.To do this, it is recommended to beat the edges with a heat-resistant insulator (for example, mineralite). The fixation of non-combustible material to the ends of the hole is carried out using nails or self-tapping screws. A distance of 25 cm must be maintained from the external contour of the sandwich structure to the edge of the ceiling.

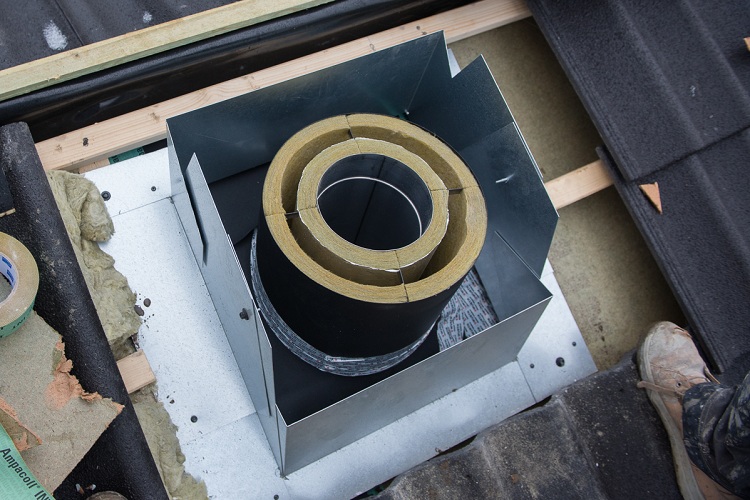

- Mounted ceiling access point or PPU. The organization of the box is quite simple: as a rule, it has ready-made, factory holes in it.

- We fasten the box to the ceiling using self-tapping screws.

- Next, you need to stretch the sandwich structure through the finished PPU. The pipe should be stretched and fixed in a strictly vertical position, without any deviations.

- The free space in the box is filled with insulating material. Mineral wool or expanded clay is well suited for this.

- In the end, you need to take care of the appearance of the structure. On the front side, it is necessary to close the hole with the pipe with a sheet made of stainless steel. Between the ceiling and the stainless sheet, it is imperative to place a small layer of heat insulator.

An important point in the withdrawal of the pipe through the roof is the waterproofing of the exit point

Important! Experts do not recommend firmly fixing the pipe sandwich. This is due to the fact that they expand during heating.

Installation of a chimney made of sandwich pipes through the roof

After putting the chimney sandwich into the attic, you must ensure that there are no combustible materials nearby. The appearance of the pipe in the attic in most cases is not so important, so the organization of additional decor elements is done as desired.

Consider the sequence of steps for installing a sandwich pipe through the roof:

- First, a hole of the required diameter is made in the roofing cake. It is recommended to cut the insulation films that are part of the roofing pie crosswise. Then it turns out 4 triangles that need to be wrapped and secured in any convenient way (for example, a stapler).

Important! The distance from the crate to the sandwich should be at least 13 cm.

- At the second stage, we install minerite at the edges of the hole.

- After the flooring of the roof material, a special device is mounted on the pipe - a master flash. This device is a silicone sleeve, the function of which is to waterproof the holes between the pipe and the roof. This device can be adjusted to the shape of the roof. This is the best solution for fixing the pipe sandwich to the roof.

- The joint between the rubber seal and the chimney flue sandwich must be treated with a heat-resistant sealant. All other joints are also treated with sealant.

- A mushroom is mounted at the end of the pipe to protect the channel from atmospheric precipitation and debris.

How to install a sandwich pipe in a bath? Installation of a chimney sandwich in a bathhouse is carried out in almost the same way as in a private house. However, there are some nuances that are worth paying attention to:

- the distance from the external contour of the pipe to the wooden ceiling (or roof) should be at least 13 cm;

- a channel located in the horizontal plane and going from the boiler outlet must have a length of not more than 1 m;

- on top of the sandwich pipe brought to the roof, it is necessary to put on a lead base, which is necessary to fix the chimney and its fitting;

Remember that from the attic side, the hole together with the pipe drawn through it must be closed using basalt cardboard and cotton wool. After that, the heat insulator is closed with a roof sheet.