The chimney is one of the main components of the heating structure. The heat transfer of the furnace, as well as the fire safety of the entire system, depends on its performance. Today, sandwich pipes for the chimney are very popular, which are distinguished by the fact that they do not accumulate condensate during the operation of the furnace, and are also quite simple to assemble and disassemble.

In order for the heating system to uninterruptedly perform its functions, you need to choose the right diameter of the pipe for the chimney

Content [Hide]

Design Features

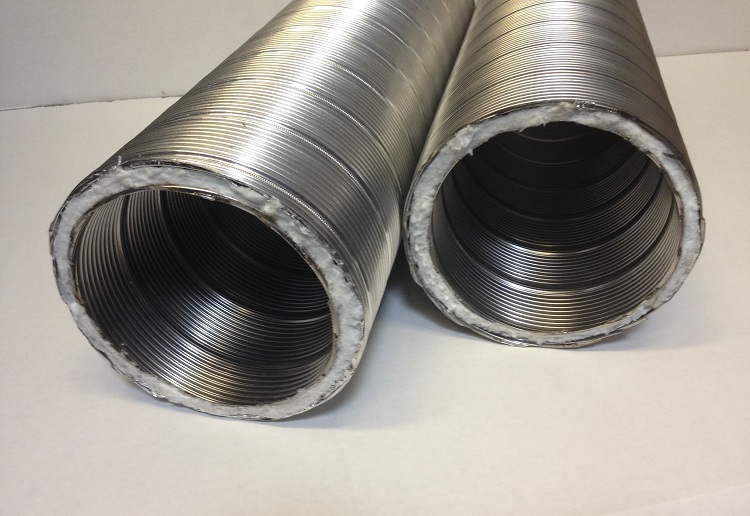

The design of the sandwich involves the use of three layers:

- The inner pipe, which is made of durable stainless steel. It is characterized by high heat resistance.

- Thermal insulation material, which is usually represented by basalt or ceramic wool, polyurethane foam (PUF), and also sometimes vermiculite.

- Protective outer pipe made of galvanized or stainless steel.

The sandwich construction has a cylindrical shape, which contributes to good aerodynamics. The joining of the layers of such a pipe is carried out by applying special glue. The installation of individual parts of the chimney is carried out using bells (as in sewer pipes).

Benefits of Using Double Tubes

Consider the main advantages of using a sandwich pipe for chimney structures:

- ease of installation. If you approach this event correctly and study all the nuances, you can independently carry out the installation of a chimney sandwich;

- the light weight of the pipes allows you to exclude such an item during installation, as the implementation of a separate foundation for the furnace;

- previous property plus compactness allow for trouble-free transportation of these products;

- a variety of shaped elements, allows you to mount the design with any configuration (with the output through the wall or roof);

- simple repair. Replacing any part of the structure is not difficult;

- the heat-insulating layer, which is located between the two pipes, allows you to reduce the temperature of the sandwich pipe outside, delaying heat. This reduces the risk of ignition;

- a cylindrical and smooth inner surface eliminates the possibility of stagnation and contributes to the efficient transportation and further removal of smoke. In addition, thanks to this design, soot formation is minimized;

- Sandwich pipes are made of anticorrosive materials; therefore, they are not threatened with destruction due to the formation of condensate and aggressive chemical compounds in the system;

- ease of use of such pipes is also considered a big plus. Of course, it is necessary to regularly conduct preventive checks and clean the chimney, but due to its design, periodic inspections are carried out less often and easier.

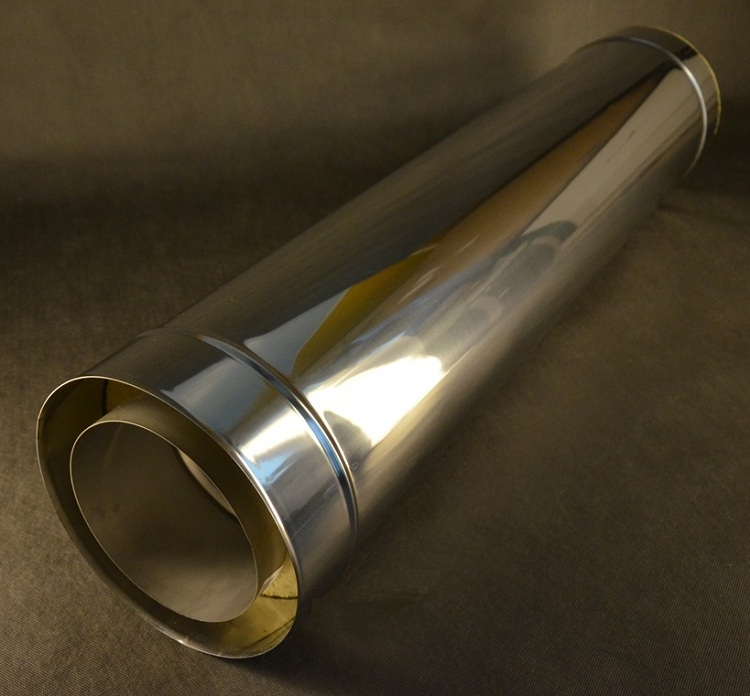

The stainless pipe does not need painting or decorative cladding; its appearance is aesthetic and does not spoil the exterior of the building

Another advantage of such products is an attractive appearance. A sandwich pipe looks good both inside and outside without any additional decoration.

Features of stainless steel pipe sandwich

Stainless steel is the most resistant to temperature extremes and, in addition, has excellent anti-corrosion properties. Stainless steel inner tubes can withstand operating temperatures up to 850 ° C and short-term temperatures up to 1200 ° C.

The best quality characteristics can be seen in two grades of stainless steel - 316 Ti, 310S. The temperature of the working medium for these species reaches 1000 ° C. Experts recommend these two options for boilers that run on solid fuel and baths, as they can withstand high heating temperatures. A sandwich pipe for a chimney made of such steel will last a very long time.

Helpful information! The best option is when both the inner and outer shells of the sandwich are made of stainless steel.

The dimensions of the cross section of the sandwich structure primarily depend on the thickness of the insulating layer. There is also a certain dependence of the diameter of the sandwich pipe for the chimney on the location of the structure. The diameter of the inner pipe is also selected in accordance with the power of the heating device. The greater the power, the correspondingly larger should be the cross section of the inner pipe. This is a very important point, as the main temperature load falls on the stainless steel inner pipe.

Consider the dependence of the diameter on the power of the heating device in more detail:

- for stoves that run on wood fuel and for gas turbine units (GTU), the cross section can be from 50 to 600 millimeters;

- for boilers running on solid fuel, the diameter is - from 50 to 700 millimeters;

- for gas piston or diesel generating devices - from 50 to 500 millimeters;

- for microturbine devices - from 50 to 300 millimeters;

- for boilers running on gas or diesel fuel - up to 200 millimeters.

In addition, it is not recommended to use fiberglass as thermal insulation. This material can be used in systems whose operating temperature is not more than 350 ° C. In bath constructions, a similar indicator can be 600 ° C and higher.

Other sandwich options

There are other materials besides stainless and galvanized steel from which a pipe sandwich for chimneys is made. This, for example, ferrous metals. Usually, a protective layer of enamel is applied to pipes made of such alloys. The construction of these parts can withstand operating temperatures up to 500 ° C and short-term up to 750 ° C.

In addition, such products have a fairly presentable appearance and resistance to the harmful effects of corrosion. Of course, the heat resistance of this design is much lower than that of stainless steel chimneys, but it is allowed to use them for fireplaces and some stoves.

Combined sandwich structures are made of stainless steel and galvanized or enamelled steel. The temperature that such chimneys can withstand is up to 600 ° C.

Insulation characteristics

Thermal insulation material, which is located between two pipes - internal and external, as a rule, is a mineral wool (basalt or ceramic).

However, in some cases, vermiculite is used for insulation. This material is obtained in a natural way, crushed to obtain granules and burned in a special furnace. All this is done in order to obtain maximum quality characteristics, which include heat resistance, light weight, etc. The cost of such material is higher than the price of mineral wool. The operating temperature that this material can withstand is 1150 ° C.

Basalt cotton wool is the most common type of insulation.The working temperature of this mineral material does not exceed 600 ° C. Such material is obtained from basalt melt. A sandwich pipe with such a heater has a rather attractive cost.

Ceramic wool is able to withstand temperatures up to 1260 ° C, which is more than 2 times higher than that of basalt material. However, the cost of pipes with such a filler is higher than for sandwiches with vermiculite or basalt wool.

Sizes of Sandwich Tubes

First of all, when choosing a suitable sandwich pipe, it is necessary to rely on the indicator of the outlet cross section of the boiler pipe. During installation, the sandwich pipe is mounted on this conclusion, so its diameter must necessarily be larger.

To date, diameters from 110 to 300 mm are found. Most often, a sandwich pipe for a chimney has the following dimensions: 0.5 and 1 m. However, there are other pipe sizes, but they are much less common.

Important! Connecting elements for a sandwich design are available with an angle of 90 ° C (corners, tees) and 135 ° C (tees).

The thickness index of the inner wall ranges from 0.5 to 1 mm. The outer wall is most often produced with a thickness of 0.7 mm. The dimensions of the outer diameter, as a rule, range from 200 to 430 mm. A layer of internal thermal insulation can be from 2.5 to 6 cm.

The dimensions of the cross sections of the inner and outer pipes are indicated, as a rule, in the technical passport for these products (for example, 110/170).

When choosing a chimney, you need to pay attention to the diameter of not only the outer, but also the inner pipe

Varieties of connecting elements

In the heating structure, in addition to sandwich pipes, the following shaped elements are present:

- Chimney-convector. It is used to divert combustion products outside the house.

- Knee. It consists of several elements docked at a certain angle. Using this device allows you to change the direction of the chimney.

- Tee. It is used in chimney structures quite often and performs the function of removing smoke and condensate.

- Audit. It is necessary in order to clean the structure of soot.

- Adapter. The most common shaped element through which the individual pipes are joined.

- Kagla. Performs traction control function.

- Weather vane and cone. These products are used to protect the system from atmospheric precipitation.

- Rosetta. An element that is used to decorate a chimney structure.

- Fungus. It is made of galvanized steel sheet and is used to protect the chimney from rain and snow. Mounted at the end of the outlet pipe.

Helpful information! It is very important to remember that the thicker the layer of stainless steel and galvanized sheet from which the inner and outer pipes are made into a sandwich structure, the longer the service life of such a system.

All these additional products are used in certain cases, depending on various factors and design features of the chimney and have diameters of 120, 150, or 200 millimeters. Calling the diameter of a sandwich chimney and its shaped elements, as a rule, imply an indicator of the cross section of the inner pipe.

How to choose a chimney sandwich?

When choosing a sandwich pipe for a chimney, it is necessary to pay attention to several factors. First of all, the quality characteristics of a sandwich structure depend on how strong steel was used in its production. In addition, it is worth paying special attention to the dimensions of the chimney sandwich and the insulating layer, which should be tightly laid between two steel pipes. You also need to carefully examine the pipe seams. They may be:

- rolled;

- laser.

Products with rolled seams are recommended to be used only for gas boilers.Laser seams provide the maximum possible sealing and are used if the chimney is used for a boiler that processes solid fuel. The inner tube in most cases is made of heat-resistant stainless steel, however, it happens that this layer of sandwich is galvanized. Such a sandwich design can only be used for gas boilers of small capacity.

If you use a sandwich product with internal galvanization - this design will not last long and will have to be changed. There are other metal varieties of internal pipes, but they are used in conditions with low temperatures or for the installation of ventilation structures.

A pipe in which both the outer and inner parts are made of stainless steel is the most reliable and durable option for the chimney

Chimney Sandwich Location Tips

Installation of such a structure as a chimney sandwich is a fairly simple event and is affordable for almost anyone. However, in order to carry out the correct installation of a sandwich design, you must be guided by certain rules:

- the height of the chimney sandwich above the vertical roof should not be lower than 0.5 m;

- if the distance from the outlet pipe to the ridge of the roof corresponds to 1.5 m, then its height should not be less than 0.5 m;

- if the roof is made of flammable materials, then chimney height need to do at least 1 m;

- if the distance from the ridge to the pipe is more than 3 m, then the height is calculated by drawing an imaginary line from the ridge of the roof to the horizontal (at an angle of 10 °).

Chimney Sandwich Pipe Life

The approximate service life for different products is from 10 to 15 years. Of course, these figures are calculated on the basis that all the rules for choosing the chimney are met (the material, diameter, thickness of the sealing layer, etc., are chosen correctly). Some owners do not take into account all these important points, as a result, the service life of the sandwich pipe is reduced and the replacement of the chimney is required after 5 years, and even earlier.

The reasons for the early breakdown of the sandwich design can be many. Moreover, even taking into account all of the above factors, you can purchase low-quality products. For example, a product can be factory-defective, so experts advise you to be careful about your choice. chimney pipes and whenever possible carefully check the design for defects.

Important! A very important point is that it is necessary to carry out preventive cleaning in the system on time. If you find any deviation in a constructive sense, you must stop operating such a system and carry out repair work or a complete replacement of the chimney.

Compliance with all the necessary rules and measures for the purchase and operation of a sandwich design is the key to the fact that it will serve you for a long period. Otherwise, an emergency may occur that may cost you and your loved ones life. If you are not sure that you can correctly select the necessary components or carry out their installation, then the best way out of this situation is to consult with specialists who will help you figure out any question.