As practice shows, elements of industrial pipelines are not enough to weld together, or assemble by means of a coupling thread. The resulting compounds will be non-separable or very unreliable. That is, both options may not suit the user. People need to form a very strong connection that provides sealing of large-diameter pipes, but allows to disassemble it if necessary. Steel flanges will help to solve this problem.

Design

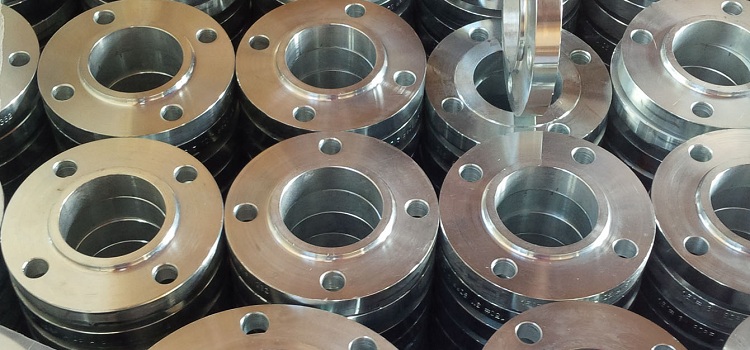

The flange connection of metal pipes is today one of the most popular methods for assembling pipelines. The considered products deserve such an attitude from professionals for many reasons. Welded flat steel flanges look like plates in which there are holes. The main one is located in the center of the plate. Through this hole, the part is connected to the pipe.

In this case, it is necessary to take into account the following requirement: the diameter of the inner hole on the ring at the flange must completely coincide with the value of the same indicator on the pipe. Then, when installing and fixing it, there will be no difficulties, and the docking will take place qualitatively and quickly.

Along the perimeter of the plate there are several holes, but already somewhat smaller in diameter. These are places for bolting. They tighten and fix the plates with bolts.

A compound of this type has both pros and cons. The main advantage is the ability to quickly remove and disassemble it. Moreover, to work you will need only an appropriate size wrench. On the other hand, the bolted connection is still inferior to welding in terms of solidity and reliability. The use of steel flanges implies in most cases their additional sealing with O-rings. Previously, this problem was solved by using rubber on the ring.

Under the gaskets on the flanges, steel flat welds on the inside even cut a channel or groove. A sealing ring is placed in it, and then screwed onto another, in everyday life called the reciprocal.

Advice! When purchasing, check that the flanges are absolutely identical. Otherwise, you will not succeed in combining them qualitatively.

Pros, Cons, and Application

The main advantages of such products, experts include:

- functionality;

- an opportunity to use at any characteristics of a working environment and on any pipelines;

- simplicity in installation;

- durability of the connection;

- reasonable cost;

- reliability.

Of the main disadvantages it is worth highlighting:

- the quality of the connection is very seriously affected by the conformity of the plates, as well as their size;

- wear of o-rings. Over time, these elements will have to be replaced with new ones.

Flange connection is used for installation of pipelines of various types, including those that operate under high pressure.

Flanges of this type are used almost everywhere. They are in demand in the assembly of civilian central pipelines, gas pipelines, domestic water supply systems, heating mains, industrial systems, etc. Against this background, the fact of the availability of GOST for these products is absolutely not surprising.

Moreover, there are several such regulatory documents. The action of each of them extends to its direction. For example, the weight of the flanges of steel welded flat, their dimensions and the used steel grade indicates GOST 12820-80. But similar parameters of collar models are determined by GOST 12821-80. There are other state standards. Some of them will be mentioned below.

Varieties

In general, the classification of steel flanges is as follows:

- cast. These are the connecting elements of fittings and pipelines made of any material. Temperature range -250 ≤ T ≤ + 600ً С. Working pressure - 1.6 ≤ P ≤ 20 MPa

- welded flat. Operating temperature range: -70 ≤ T ≤ + 300ً C. Able to withstand pressure 0.1 ≤ P ≤ 2.5 m Pa;

- for butt welding. Work at a temperature of -250 ≤ T ≤ + 600ً C. Able to withstand operating pressure 0.1 ≤ P ≤ 20 MPa;

- steel flanges equipped with a welded ring. The operating temperature range is -30 ≤ T ≤ + 300ً C, pressure 0.1 ≤ P ≤ 3 MPa.

Welded-type fittings are put on during installation on the pipe end, and then fixed with welds (2 seams are enough). Elements for butt welding are fastened with one seam. It is located between the collar of the flange and the pipe cut. The design of products with a welded ring consists of two parts - a ring and a plate of identical diameter. In this case, one ring is welded to the pipe, and the flange itself does not lose a degree of freedom, due to which it can scroll around its own axis.

Good to know! Such a technical solution is aimed at use in hard-to-reach places or in areas where regular maintenance of the pipeline or its repair is necessary.

Flanges for connecting pipes to equipment or vessels are classified in accordance with GOST 28659 in the following varieties:

- octagonal section. Temperature -70 ≤ T ≤ + 550ً C, pressure 6.4 ≤ P ≤ 16 MPa;

- for butt welding. The temperature range is -70 ≤ T ≤ + 540ً C, operating pressure 0.7 ≤ P ≤ 6.5 MPa. The sizes of steel flanges of this type range from 40 ... 4000 mm (meaning their diameter). GOST 28759-3;

- flat. Operating temperature -70 ≤ T ≤ + 300ً C, pressure 0.3 ≤ P ≤ 1.7 MPa. Similar flanges are available in sizes that allow docking equipment and vessels with a diameter of 400 ... 4000 millimeters. GOST 28759-2.

For the most complete information, it is worth mentioning the following term - an insulating flange connection (abbreviated as IFS). For its arrangement flange constructions of any type can be used. The use of IFS allows protecting pipelines from electrochemical corrosion, a phenomenon that acts as the main reason for the accelerated wear of systems laid underground.

The design of the insulating flange connection is 2 flange-tightening pins, between which a gasket of dielectric material is laid. As a rule, it is paronite or thermostabilized graphite. This design prevents the distribution of electric current through the pipeline, limiting it to a certain section of engineering communications. IFS contributes to a significant increase in the service life of underground pipelines. It has been used for 15-20 years, after which the dielectric gasket changes to a new one. The replacement procedure is performed using the so-called accelerators - wedge-shaped jacks. The force they produce spreads adjacent flanges. Modern industry produces hydraulic and manual (mechanical) accelerators. The first develop a force of 15 tons.

Characteristics and prices

Since steel flanges are subject to strict standardization, their parameters are very clearly defined.The departure of manufacturers from assortment sizes and technology is prohibited. Before you buy the necessary batch of these products, require a certificate from its manufacturer.

The main characteristics are the dimensions of the connecting parts. With regard to steel flanges, even a special certificate is valid, in which all their sizes are painted. In order not to encounter any further troubles, examine the passport of the flanges for compliance with this document, and if there are differences from the purchase, it is better to refrain.

Flanges must be manufactured in accordance with GOST and have all the necessary certificates confirming their quality

It should be remembered that the connections are completely identical to each other in their outer and inner diameters. Also pay attention to the level of working pressure that the flange can withstand for a long time.

Helpful information! This indicator is measured in bars and indicated by PN symbols. The price of flanges is a derivative of this characteristic, as well as of the conditional diameter (DN).

For example, you can purchase connectors with PN 16 and DN 50 mm for little money - from 3 to 5 dollars. But for a model with a remote control of 150 millimeters, you will have to pay 11-13 dollars.

Price differences are also inherent in various types of flanges. So, you can buy butt welded steel flanges also inexpensively - for 2-4 cu, if a part with an internal cross section of 50 mm is considered. A collar model with identical characteristics will cost $ 5-6.

The dimensions and type of steel flanges determine their weight. It is understood that the weight of collar products is greater than that of steel flat connectors. However, the weight parameters are not always in the focus of the buyer’s attention, since they do not have any specifics on the operation and scope of use of the flanges.

Among the most critical characteristics is the grade of steel used to manufacture the part. In industry, steel flanges made of stainless steel are most often found. This fact is quite obvious and at the same time justified. Indeed, such stainless steel products are characterized by greater reliability and durability compared to connecting elements made of ordinary alloy steel. But they are sold at a price almost two times higher. Here you need to prioritize for yourself. And when choosing, you must be guided by the conclusions made.