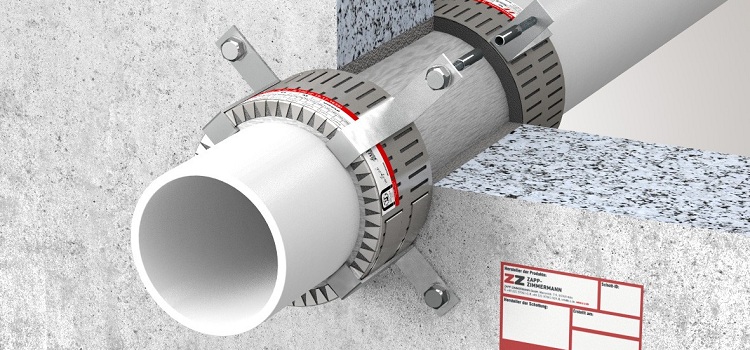

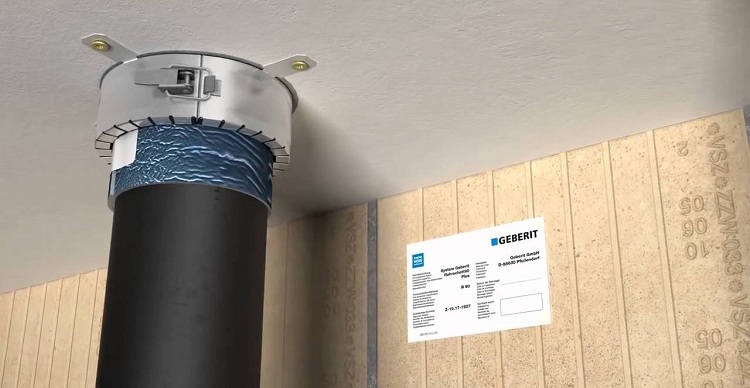

A fire protection sleeve (PPM) or cut-off is a product that is used for passive protection against the spread of fire in the event of a communication fire. Mount this element at those points where the pipeline crosses a variety of fences. Such couplings are used in various polymer communications: water pipes, sewer systems, etc.

Content

Scope of use of fire couplings

Today, pipes made of modern polymers have won great popularity in the construction market: polypropylene (PP), polyethylene (PE) and polyvinyl chloride (PVC). This is due to the fact that the cost of plastic products is lower than that of metal counterparts, and the transportation and installation of such polymer pipes is simple due to their low weight.

Plastic pipelines are widely distributed and are used almost everywhere. It should be noted that they are laid not only for economic purposes, but also at various enterprises. Water and sewer systems made of polymer materials pass through many floors.

Important! Installation of fire cut-outs is a mandatory measure, which is regulated by the normative documentation of fire safety ФЗ 123 dated 07/22/2008.

In case of fire and fire spread, the plastic pipe softens due to high temperature. The temperature required for polymer communication to melt is approximately 180 ° C. At this temperature, the pipes soften and then burn out, due to which fire can spread to neighboring floors through the holes formed in the ceilings.

Self-activating fire cut-offs operate on the principle of conventional fixing elements for pipelines. In sewer systems, this principle looks like this: the coupling connects a pipeline that does not have a special connecting element - a socket. The service life of such couplings may be 50 years. The main difference between the fire protection sleeve and the conventional retainer is that a special polymer insert is located inside the cut-off, which expands under the influence of high temperatures.

Fire couplings play the role of a barrier, eliminating the possibility of the spread of fire and smoke through floors and walls. In case of fire, the PPM couplings block the passage points of the polymer pipes through the ceilings and walls, by expanding the polymer liner.

Fire Coupling Requirements

MRPs are used to prevent the fire from spreading to neighboring floors, so their installation is recommended, especially in cases where communication is located at the enterprise.

The fire clutch contains a special substance, which at high temperature increases in volume up to 10 times. The direction of expansion of this substance is both internal (inside the pipe) and external.Based on this, it can be noted that the substance of the fire-fighting sleeve fills the openings in the floors and walls, blocking the free access of oxygen and stopping the source of ignition.

In addition, according to the provisions of fire safety (PPB), such devices are mounted to create belts in residential and industrial buildings.

Consider the main types of pipes on which the installation of fire compartments is recommended:

- storm sewer pipelines. In this case, the installation of cut-offs is carried out when the communication passes through the slab (at the entrance to the building);

- plastic sewer pipelines. The rules stipulate that when passing through technical floors and accessing the roof, installation of fire couplings is recommended;

- plastic water pipes. It is recommended to equip water utilities made of plastic with cut-offs in the places of passage through the floor floors.

In addition, the regulatory documentation says that the installation of cut-offs is necessary if the communication is made of a polymer such as polypropylene.

Advantages of Fire Couplings

Like any other product, fire couplings have several advantages. Consider the main advantages of such devices:

- cutoffs are made of refractory materials. Thermodynamic material provides reliability when blocking technical holes;

- ease of installation and, in addition, the ability to quickly dismantle the device;

- no special tools and equipment are required to install the fire protection sleeve. It is enough to have a punch and fixing elements (dowels);

- fire cut-off is highly resistant to corrosion;

- fire couplings have a high coefficient of moisture resistance, which allows you to mount these devices in high humidity conditions;

- the service life of this device is usually about 50 years, however, some variations in the shelf life depending on the manufacturer are possible.

Fire couplings have many positive qualities, their use is recommended by appropriate documentation. The efficiency and reliability of these devices, as well as the long operational period, allowed them to occupy a confident position in the construction market.

The device and materials used for the manufacture of individual PPM elements

The structural elements that make up the cut-offs are made of different materials and, accordingly, have some differences in technical characteristics.

Note! A fire clutch, as a rule, consists of two main components: a body made of metal and a polymer liner.

Consider the materials from which the individual components of the planning run are performed:

1. Case. The body of the fire protection sleeve is made of steel obtained by cold rolling or galvanized. The thickness of the body (cuff) can be from 0.5 to 2 mm. In addition, it is worth noting that at the production stage the case is painted with weather-resistant paint.

2. The castle. It is usually made from durable galvanized steel. The locking joint (like the case) has a protective paint layer, which guarantees a long service life of this element of the fire protection sleeve.

The main technical characteristics of fire couplings are presented in the table below.

Table 1

|

Couplings, mm |

Outer diameter mm |

Weight, kg |

| 160 | 210 | 1,25 |

| 110 | 130 | 0,26 |

| 50 | 65 | 0,15 |

| 40 | 54 | 0,08 |

| 32 | 46 | 0,07 |

| 25 | 35 | 0,065 |

| 20 | 33 | 0,06 |

3. Bent (inward) teeth. The teeth perform two functions:

- fastening function, holding the polymer refractory liner inside the part;

- guiding function, ensuring the extension of the liner in case of fire in the necessary directions, which contributes to the rapid clogging of the technological hole.

4. Petals of fastening. Such elements are fixed with a hole, bend effortlessly and have a length of 35 mm. This length provides easy and convenient installation. In addition, it is worth noting that most companies produce individual parts on order. Such parts may have mounting petals of 70 mm or more. Fire cut-offs with such petals are mounted on pipes that are laid in metal casings. This technology is used in the construction of monolithic buildings.

Fire Coupling Installation Steps

Installation of fire cut-outs does not require the use of special equipment and is quite simple. Consider the phased installation of PPM on the pipe:

- First, you need to translate the mounting tabs of the product in the working position. To do this, they need to be bent at a right angle (90 °).

- At the second stage, it is necessary to unbend the coupling, and then put it on the pipe.

- Next, it is necessary to mark the places on the wall or the floor, in which the fire clutch will be mounted. This is very simple - through the holes in the lobes of the mount.

- At this point, drill holes at previously marked points.

- Conventional dowels are driven into the holes.

- Next, you need to put on the polymer thermodynamic liner.

- Then the PPM case is put on a polymer insert.

- At the eighth stage, the housing is tightened by means of a metal lock connection. It is worth noting that the design of the lock for different models may vary.

- Next, you need to fix the resulting structure on the wall or ceiling. To do this, you need anchor bolts.

- The niche in which the fire coupling is mounted is sealed with cement mortar.

Helpful information! In order to fix the MRP on the working surface, it is recommended to use only metal dowels. This is due to the fact that in case of fire, plastic fasteners are likely to melt.

Fire safety should be provided at facilities of any purpose, and pipeline systems are no exception. Couplings are simple but effective products used in both domestic and industrial conditions.