A cast-iron flange tee is a product that is used to branch the auxiliary line from the trunk communication. Also, through these connecting elements, shutoff valves and measuring equipment are mounted for communication. Such parts are used, as a rule, for water supply engineering networks. A cast iron tee of flange type is mounted using a special sealing gasket and tightened with bolts equipped with nuts.

Content

Production and use of cast iron flanged tees

Today, flange connecting products of this type are widely used for joining individual elements of pipeline structures. Using this connecting element, it is possible to branch the flow of the working medium in three directions.

The use of such products allows the installation of pipeline structures with different configurations. And modern industry is able to give cast iron high technical characteristics that increase the operational life of these devices.

Let's consider for which communications cast iron flanged tees are most often used:

- plumbing systems;

- heating networks;

- gas pipeline structures.

Important! The temperature of the working medium in communications where such cast-iron connecting elements are mounted must not exceed a certain indicator, which is 175 ° C.

In addition, such products are often used in plumbing communications that transport cold water. Pressure indicators in such systems reach 1.0 MPa (10 atmospheres). For the manufacture of tees, certain brands of cast iron are used. As a rule, special brands are taken not lower than SCh20. The dimensions and weight of the products are presented in table No. 1.

Table 1

| TF sizes | Weight kg |

| 100 x 100 | 33,2 |

| 150 x 100 | 51,7 |

| 150 x 150 | 61,6 |

| 200 x 100 | 67,9 |

| 250 x 250 | 120,3 |

| 300 x 100 | 106,8 |

| 300 x 250 | 129,9 |

| 300 x 300 | 138,0 |

| 400 x 100 | 191,3 |

| 400 x 400 | 282,5 |

| 500 x 100 | 206 |

| 500 x 300 | 272 |

| 500 x 500 | 359 |

| 600 x 150 | 273 |

| 600 x 300 | 343 |

| 600 x 500 | 434 |

| 600 x 600 | 498 |

| 700 x 150 | 440 |

| 700 x 200 | 442 |

| 700 x 250 | 447 |

| 700 x 500 | 555 |

| 700 x 700 | 699 |

Product Advantages

Pig-iron tee with flange connection method, like any other product, has its own advantages. Consider the main operational advantages of cast iron flange tees:

- these products are cheap, if we compare this indicator with brass counterparts;

- can be used in sanitary communications, especially in cases where there is no need to install presentable equipment;

- differ in high strength characteristics. The most durable is considered to be a connecting tee VChShG (high-strength cast iron with spherical graphite). Models made of such a material can withstand pressures of 25 atmospheres, if their cross section is less than 300 m. Models with cross-sectional indicators exceeding 300 mm are used in communications with pressure indicators not exceeding 20 atmospheres.;

- they are highly resistant to the harmful effects of corrosion due to epoxy powder coating;

- in addition, such products have good wear resistance and do not even lose their performance characteristics over time;

- installation of these parts does not require special construction equipment;

- these devices are characterized by a high coefficient of fire resistance. In case of fire, such products do not ignite;

- the life of these products can reach 50–80 years under normal use.

Varieties and installation

Depending on the operational features, all cast iron fittings with flanged type of connection are divided into two main types. Consider them:

- direct;

- transient.

Straight cast iron tees with flange type of connection are used in cases where it is necessary to join three pipes with the same cross-sectional indicators. Direct products have bends that are identical in their geometric characteristics.

Transitional cast iron products with a flange type of connection are used for joining three pipes in case one of them differs in diameter from the other two. Accordingly, the cross-sectional index of one of the taps of the part will differ from the other two.

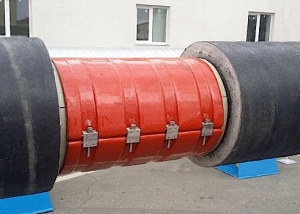

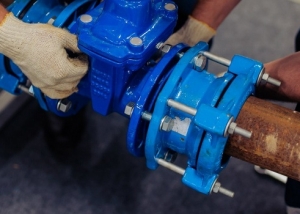

Installation of such devices is performed as follows:

- First of all, it is necessary to dock the connecting tee with one of the pipes. Such an attachment, as a rule, is performed in the same way as the docking of another popular connecting piece - a branch.

- Next, you need to dock the two remaining bends of the connecting part with the pipes. A special gasket is inserted between the flanges, after which the resulting structure is fixed with bolts equipped with nuts.

Product sizes over 800x200 and their weight are shown in table No. 2.

table 2

| TF sizes | Weight kg |

| 800 x 200 | 562 |

| 800 x 250 | 566 |

| 800 x 500 | 689 |

| 800 x 800 | 1003 |

| 900 x 200 | 672 |

| 900 x 250 | 678 |

| 900 x 400 | 809 |

| 900 x 500 | 814 |

| 900 x 700 | 1090 |

| 900 x 900 | 1254 |

| 1000 x 250 | 956 |

| 1000 x 600 | 1264 |

| 1000 x 700 | 1297 |

| 1000 x 800 | 1351 |

| 1000 x 1000 | 1570 |

| 1200 x 300 | 1311 |

| 1200 x 700 | 1729 |

| 1200 x 800 | 1966 |

| 1200 x 1000 | 2409 |

| 1200 x 1200 | 2603 |

Note! Installation of a cast-iron flange tee is made in any necessary position. When installing this product, experts recommend using washers under the heads of bolts without fail. This is necessary so as not to damage the anticorrosive epoxy layer.

A wide range and excellent strength characteristics, as well as other advantages allow the use of a connecting cast iron flange tee in systems with different configurations. Installation of such tees is easily carried out using a conventional wrench, which is very convenient.