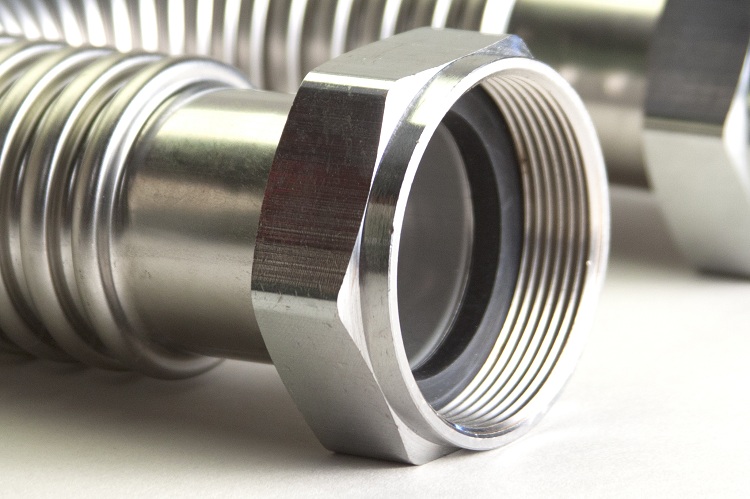

A bellows water connector is a special fixture, which is a corrugated hose made of stainless steel. This product is very practical, however, inferior in flexibility to conventional metal-braided rubber hoses. For the correct selection of the bellows model, you need to familiarize yourself with its features and technical characteristics.

A bellows connection for water or gas is a flexible part that remains strong and leakproof even with repeated deformations associated with pressure and temperature

Content

What is it and where is it used?

Flexible bellows eyeliner for water, made of stainless steel and has a corrugated structure. Such devices are used in cases where the installation of conventional pipes is difficult or impossible.

Consider in which cases a bellows eyeliner is mounted:

- connection of various plumbing equipment to water supply;

- gas supply from the gas pipeline to stoves, boilers, etc .;

- for the organization of connections during the installation of various climatic equipment (for example, air conditioners);

- as well as bellows models of eyeliners are widely used to connect sprinklers (sprinklers), which are part of automatic fire extinguishing systems;

Note! It should be noted that the operational area of the flexible bellows-type water connection is expanded if it is used in combination with various fixation fittings.

Such combined designs are used in enterprises and are part of the equipment that delivers a variety of products:

- air and other gases;

- petroleum products;

- aggressive chemicals.

Today, in addition to bellows liners, there are other varieties of these devices. The range of such hoses is incredibly wide, which allows you to expand the operational scope of the hoses. When choosing an eyeliner, first of all, you should pay attention to the material of the product, as this is considered a decisive factor.

Varieties of Flexible Eyeliners

Consider the main varieties of flexible eyeliners on the material of manufacture:

- rubber hoses equipped with a special stainless steel braid. In some cases, aluminum or nylon is used as the braid, and sometimes there is no braid at the rubber hose;

- cross-linked polyethylene hoses. This material is characterized by high flexibility;

- stainless steel corrugated tube (bellows eyeliner).

It should be noted that each of the above models is distinguished by its pros and cons. Rubber hoses equipped with an aluminum braid are used to connect water or gas and have a service life of up to 3 years. The pressure that such devices can withstand does not exceed 0.5 MPa, and the temperature resistance is not more than 80 ° C. The main disadvantage of this model is its low resistance to the harmful effects of corrosion.

The stainless steel reinforced rubber hose is more reliable than the first option in terms of performance. The pressure indicators that such a hose can withstand are 1 MPa, and the maximum temperature of the working medium reaches 95 ° C. The operational life of such models is about 10 years.

Rubber flexible eyeliner equipped with a nylon braid is very popular in today's market. The service life of such models in a braid of polymer filaments can reach 15 years. The pressure indicators that such models are able to withstand are 2 MPa, and the maximum allowable temperature of the working medium is -110 ° C.

A product made of durable cross-linked polyethylene, equipped with a metal braid, is considered quite reliable. Such models are characterized by high rates of resistance to corrosion and aggressive chemicals. However, polyethylene liners have temperature limits.

Bellows models of eyeliners are made of stainless steel and feature a corrugated surface. Such products are far superior to all previous types in their technical characteristics.

Design and features of bellows water connections

The bellows model is made from different grades of stainless steel (for example, AISI 304). The manufacturing process of this device itself can take place using various technologies. Depending on the manufacturing technology, two main types of bellows hoses can be distinguished:

- welded;

- seamless.

Regardless of the technology of execution, bellows products have almost the same technical characteristics. The wall thickness of these devices, as a rule, is 0.3 mm. In addition, they are all equipped with special structural elements - union nuts.

The bellows nuts are mainly made from the same material as the liners themselves. However, in some cases, these elements can be represented by brass or bronze. To increase the service life, brass and bronze nuts are coated with a protective layer of nickel or chromium. And also it is worth noting that to obtain the most reliable nut-hose connection, the end of the eyeliner, consisting of approximately 2-3 rings, is folded.

Helpful information! Bellows water hoses cannot be mounted without a special element - a lock ring. This part ensures that the fold and the special gasket are uniformly joined to the pipe or fitting during installation.

In addition, in order to dock the bellows hose with the equipment under the fitting, special adapters are used. Adapters are made of steel or brass and, among other things, ensure the docking of this device with pipes, the cross-sectional indicators of which differ from the diameter of the connection itself.

Bellows Hose Performance

Stainless steel is a very reliable and durable material. It has resistance to corrosion and aggressive chemical compounds, and also has resistance to temperature fluctuations. Let us consider in more detail the characteristics of corrugated bellows liners made of stainless steel:

- the operating life of bellows models can reach 20 years (and in some cases more);

- temperature indicators that bellows models can withstand vary from −40 to +200 ° C;

- the operational pressure of such products varies depending on the cross-sectional index of the hose and the thickness of its walls, however, in most cases, stainless steel bellows models can withstand from 1.5 MPa to 3 MPa.

In addition, it is worth noting that the most reliable part that is part of the flexible bellows eyeliner is a special gasket. The gasket is made of the following materials:

- paronitis;

- fluorine-containing polymer;

- copper.

The sealing element, as a rule, experiences the same pressure as the bellows device itself. Based on this, experts recommend the use of gaskets with a thickness of at least 2.5 mm.

The excellent performance characteristics of stainless steel make the bellows water hose a versatile fixture. These products are allowed to be used for:

- communications of cold and hot water supply;

- heating communications;

- gas pipelines.

Benefits of Using Stainless Steel Bellows

Consider the main advantages of using flexible corrugated stainless steel bellows eyeliners:

- resistance to oxygen diffusion;

- stainless steel is a fire resistant material;

- stainless steel is an environmentally friendly material and does not emit any harmful substances that can cause any harm to human health;

- high wear resistance.

Important! It is worth noting that during installation in the case of bending the bellows hose, it does not change the shape of its working section (it does not pinch). This is very important, since in this case the same pressure values are maintained along the entire length of the hose.

In addition, the use of such hoses in production is an ideal option, as they can be used to transport aggressive working environments and oil products. Since these devices are durable, they are allowed to be used for transporting bulk solids.

But such products have some disadvantages. For example, stainless steel bellows are inferior to rubber hoses in terms of flexibility. Because of this, the installation of bellows connections is not always convenient, especially in confined spaces. However, this property is also a virtue, since the device is able to maintain and maintain its shape without supporting structures.

Eyeliner Tips

The following rules should be followed when choosing the right sizes of bellows water inlet:

- Before purchasing this product, you need to find out the water temperature and pressure indicators in your system, which will allow you to buy a product that meets the necessary parameters;

- the diameter of the product is determined by the consumption of water of one or another plumbing equipment. The optimum cross-sectional indicators for connecting to the toilet water pipe are 8 mm, for the sink - 10 mm, and for the bath - 15 mm;

- the length of the bellows eyeliner is determined on a case by case basis. It is not recommended to install such a device in conditions of too limited space. In addition, the hose should not be too tight.

- product fittings must not have any defects or deformations.

If necessary, you can always consult with a specialist who will help to choose the necessary device for a particular case and explain to you all the nuances of using and installing such an eyeliner.

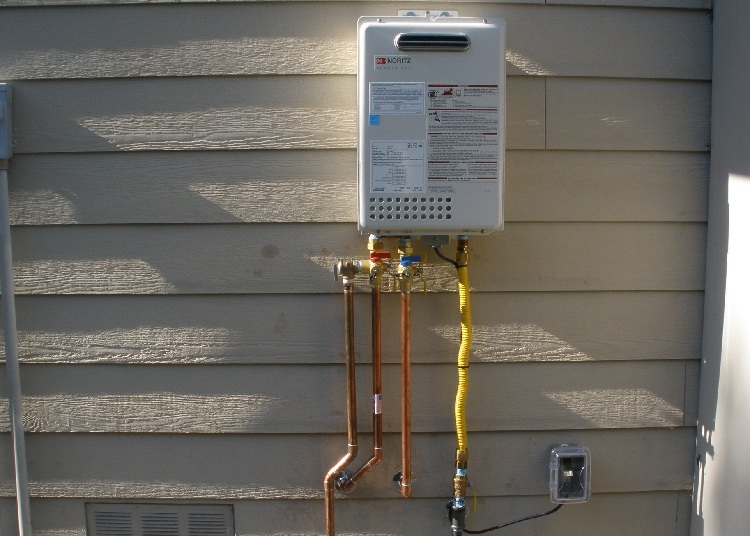

Bellows gas connector

Of the three main types of connections, it is recommended to use a bellows hose to connect gas. This is due to the fact that it has the highest technical characteristics and is very reliable. Such hoses easily carry the pressure created in the gas pipe by the gas stream. The bellows, as mentioned above, is a stainless steel corrugated hose equipped with two fittings for connection to a pipe and device (stove, boiler, etc.).

The gas supply is attached to the pipe and equipment by means of union nuts. As a gasket, plastic metals are used, among which:

- copper;

- aluminum.

It is worth noting that the sealing element in this case can also be made of a polymer substance. The hose itself is made of stainless steel, which is marked AISI 316. And the fittings are made of steel with increased strength with the marking AISI 304 or AISI 303. In addition, the fittings can be made of carbon steel.

Advice! It is best if both the hose and fittings are made of the same material. This eliminates the possibility of an electrochemical reaction (during welding) between the structural elements of the supply. In other cases, the destruction of the weld is possible.

If the nipples are soldered with tin or silver to the corrugated hose or glued to it, then such a connection will not be durable and will not last long. In addition, it is worth noting that the price of bellows gas hoses is at least 2 times higher than ordinary rubber hoses equipped with a metal braid or a braid made of a polymer material.

A bellows that undergoes a special annealing procedure can stretch, increasing its length by 2 times, however, such stretching negatively affects the rigidity of the device and is not recommended by specialists. Corrugated bellows inlets are resistant to pressure up to 0.6 MPa, and the temperature range for such products is from −40 to +200 ° C.