The sewer system will reliably fulfill the functions assigned to it only if it installation ensure the absence of potential leakage sites. This concerns both the correct laying of pipes and the complete sealing of their joints. Builders usually check whether the sewage is leaking, and if not, the commission signs the acceptance certificate for the facility. But due to wear, the joints of the sewer pipes can leak. How to prevent this phenomenon, and what to do if it does occur?

Content

Sealing Materials

It is known from construction practice that re-sealing joints of sewer pipes and deformed joints in terms of work volume is comparable to arranging the system from scratch. Therefore, this process should be approached with all seriousness.

Important! When arranging an external sewage system, it is necessary to exclude the presence of leaks not only from the inside of the pipeline, but also into it. So you will avoid overflow of the drainage system, which may arise from the penetration of groundwater into it.

Today, the following materials are most popular:

- silicone sealants;

- cement mortar and resin tow;

- tapes for sealing.

The most popular are silicone based products.

In addition, modern industry produces special tools. So, if you are looking for how to seal sewer pipes made of ceramics, pay attention to oil bitumen and asphalt mastic. It will be the best choice. And you can reliably seal the socket joints of cast-iron pipes with the help of technical sulfur.

The most common sealing methods

Silicone sealants. This material is a mastic that can harden under the influence of air. One of the advantages of silicone sealant is the absence of the need for preliminary surface treatment of pipes with primers. For its manufacture, silicone rubber is used, in which special additives are added that enhance the degree of adhesion and, accordingly, the strength of the sealing layer.

Performing work takes a minimum of time and does not require professional skills. For extrusion, a mounting gun is used. If it is not at hand, and the sewer pipe flows at the joints, you can use a simple hammer, the handle of which will serve as a piston. Upon completion of the vulcanization process, silicone mastic will turn into a kind of substance similar in its properties to rubber.

Table number 1. Silicone Sealant Consumption

| Meters per cartridge 110 milliliters. | |||||||

| Sealing layer width, millimeters. | |||||||

| Depth of a layer germ., Mm | 25 | 20 | 15 | 12 | 10 | 7 | 5 |

| 5 | ˗˗˗ | ˗˗˗ | ˗˗˗ | ˗˗˗ | 6,0 | 8,0 | 12,0 |

| 7 | ˗˗˗ | ˗˗˗ | ˗˗˗ | 3,0 | 4,0 | 6,0 | ˗˗˗ |

| 10 | ˗˗˗ | 1,5 | 2,0 | 2,5 | 3,0 | ˗˗˗ | ˗˗˗ |

| 12 | 1,0 | 1,2 | 1,7 | 2,1 | ˗˗˗ | ˗˗˗ | ˗˗˗ |

| 15 | 0,8 | 1,0 | 1,3 | ˗˗˗ | ˗˗˗ | ˗˗˗ | ˗˗˗ |

| Meters per file pack 600 milliliters. | |||||||

| Sealing layer width, millimeters. | |||||||

| Depth of a layer germ., Mm | 25 | 20 | 15 | 12 | 10 | 7 | 5 |

| 5 | ˗˗˗ | ˗˗˗ | ˗˗˗ | ˗˗˗ | 11,0 | 15,0 | 23 |

| 7 | ˗˗˗ | ˗˗˗ | ˗˗˗ | 6,0 | 7,0 | 11,0 | ˗˗˗ |

| 10 | ˗˗˗ | 3,0 | 4,0 | 5,0 | 6,0 | ˗˗˗ | ˗˗˗ |

| 12 | 2,0 | 2,4 | 3,0 | 4,0 | ˗˗˗ | ˗˗˗ | ˗˗˗ |

| 15 | 1,4 | 1,9 | 2,5 | ˗˗˗ | ˗˗˗ | ˗˗˗ | ˗˗˗ |

Cement mortar and resin tow. Sealing sewer pipes using these materials is a classic way to eliminate leaks. It is performed by caulking 2/3 of the depth of the socket with a resin bundle, followed by pouring in the remaining 1/3 of the cement mortar made on the basis of cement grade M300. Cement mortar is prepared in a ratio of 1: 9.

For those homeowners who are looking for ways to close up the joints of the sewer pipe with the lowest labor costs, it is recommended to use a special expanding waterproof cement.In this case, they will be able to seal the problem area without a resin tow. This is due to the fact that such cement quickly hardens and simultaneously expands. The solution must be prepared immediately before use, mixing cement with water in a ratio of 1: 2.5.

Important! The bell-shaped joint should be centered, fixed and only then carefully filled with the prepared mixture.

Self adhesive tape. This material is considered to be a highly effective sealant. In addition, dielectric and anticorrosion properties are inherent in the tape. Not the least role in its high popularity is played by ease of use.

Self-adhesive tape, or FUM tape, is used to seal bends, insets, plugs, turning angles and, of course, when the sewer pipe flows at the junction. In the latter case, you must perform a certain sequence of actions. The first stage is the preparation of the surfaces of joined pipes for the upcoming procedure by cleaning from dirt and dust. After allowing the surfaces to dry, if necessary, coat them with a primer.

Next, the tape is neatly with good constant tension wrapped in a spiral around the connected pipes. In this case, it is necessary to prevent the formation of any, even small, folds. To seal securely, wrap pipes with 50% overlap. Then the surfaces and the joint itself will be covered by two layers of self-adhesive tape.

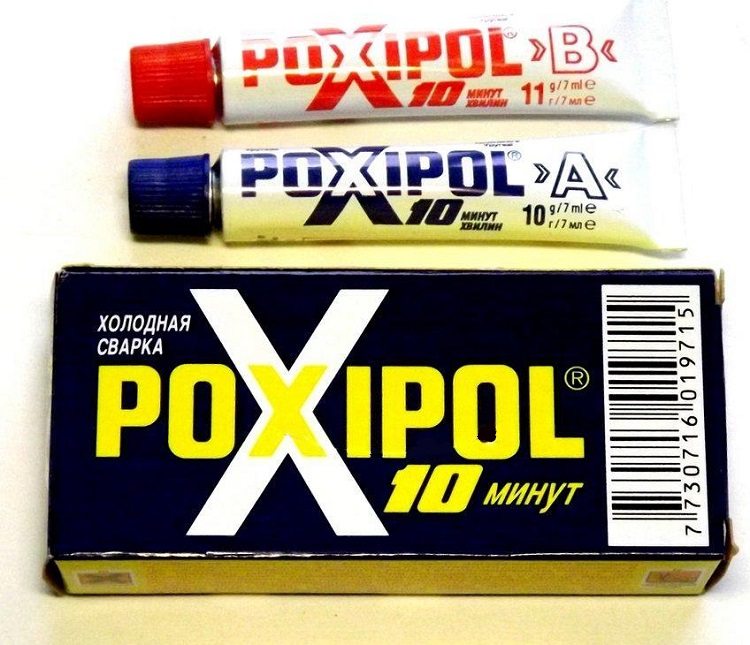

Cold welding

Cold welding is a mixture of epoxy with special fillers. It is they who give the created product the required qualities, including strong surface adhesion. Thus, the roughness present on the joined surfaces only contributes to their more reliable adhesion to each other.

In appearance, cold welding resembles two-color plasticine. Before use, it is necessary to knead it and mix both colors until a uniform shade is obtained. Then this mixture should be pressed as quickly as possible to the brushed, dried and thoroughly fat-free course of the leak.

One of the significant advantages of this material is its excellent adhesion to the surface on which moisture is present. Thus, if a sewer pipe leaks at the junction, the use of cold welding allows you to quickly seal an existing leak.

The connection created in this way will become reliable after 1 ˗ 24 hours. The exact time depends on the amount of material used and temperature conditions. But in any case, for this period you have to refuse to use the sewage system.

How to seal a joint of plastic and cast iron pipes

If a pig-iron sewer pipe flows, the owner of the house can replace the damaged segment with a piece of pipe from the same material. But there is an alternative option in the form of plastic products. However, in this case, it is necessary to know the nuances of how to seal the sewer pipe, which consists of components that differ in their characteristics.

To achieve a good result, first of all, you should purchase rubber or polymer adapters. Having done this, you can get to work. First you need to clean the cast-iron bell from rust and dirt. To improve the level of tightness, it is then recommended to degrease it. Next, a layer of silicone sealant is applied to the inner surface of the bell. The same operation must be performed on the outer surface of the adapter pipe. Then this structural element is carefully inserted into the bell. Upon completion of the polymerization process, the pipe joint with the plastic part is connected to the pipeline.If there is no spare pipe, the best solution to eliminate leaks would be to use a metal clamp.

You can purchase such a mount already with a rubber seal, or you can cut a piece that is suitable in size yourself. A clamp is generally a universal solution to many problems associated with pipe repair.

Helpful advice! For best results, rubber pads are applied to the problem area in one or even two layers, after which this design is tightened with screws.

You should not discount the easiest way to seal the joints of sewer pipes: sealing them with paint. Although this method is rarely used, it also gives good results. Moreover, on all types of sewer pipes. It is performed in two stages: first, the bell must be hammered with a cloth and filled with paint. Then, using a screwdriver, the contents of the bell are well rammed. After solidification of the resulting mass, you can begin to operate the repaired drainage system.

The following factors affect the choice of a suitable sealing option for sewer pipes: the location of the pipeline and the material from which it is made. But know: you can do this job with your own hands. To do this, you just need to clearly set yourself the task, carefully study the instructions for using this or that material and follow the tips of common sense.