Fittings for sewage made of polyvinyl chloride (PVC) are shaped elements that are used in the installation of sewer structures and act as connecting elements. Through these products, individual elements of the sewer systems are docked. The range of these polymer products is very wide today, which allows you to mount sewer structures of almost any configuration.

Content

Feature of PVC sewer fittings

Today, pipes for sewer systems are made from modern polymeric materials, such as: polyethylene (PE) and polyvinyl chloride (PVC). Shaped parts of sewer pipes are also made of these materials. The most demanded are sewer pipelines made of polyvinyl chloride, as they have many advantages over others (especially when compared with old cast-iron sewer structures).

Note! The use of PVC fittings allows you to quickly and easily install sewer, as this does not require welding equipment or other specialized tools.

We can note with certainty the fact that the use of connecting elements made of this material increases not only the operational properties of the mounted system, but also increases its shelf life in general.

The most popular such connecting parts for the installation of sewer structures in apartments and private houses. PVC fittings have a long-term heat resistance of no more than 80 ° C. In addition, they can withstand short-term exposure to temperatures up to 95 ° C. Pipes and fittings made of this material can transport not only drains, but also chemicals. Chemicals transported through such pipelines have a certain pH range (from 2 to 12).

Benefits of Using PVC Fittings

PVC sewer fittings have many advantages that distinguish them from other materials. Consider these advantages:

- low weight. This advantage is considered one of the main, since the small weight of the shaped elements made of polyvinylchloride provides high-speed installation of the sewer structure without any special costs. Installation of polyvinyl chloride products can be performed alone. The low weight of these devices simplifies their transportation;

- long service life. The shelf life of such products, as a rule, is at least 30 years (in some cases more);

- high resistance to harmful corrosive effects;

- resistance to aggressive chemical compounds;

- high coefficient of moisture resistance;

- smooth inner walls. Thanks to the perfectly smooth inner walls, PVC products are not prone to overgrowing due to the accumulation of salt deposits;

- ease of installation.Labor costs during the installation of the sewer system using PVC connecting fittings are minimized. A sewer structure of this kind is mounted like a designer (the edge of the first pipe is put on the end of the second).

- the ability to mount the design of almost any configuration.

Polyvinyl chloride products are popular and easy to assemble and, in addition, have high performance characteristics. Reliability and a long service life are two main guarantees that are inherent in products made from this material.

Types of Sewer PVC Fittings

All sewer fittings made of polyvinyl chloride are divided into two main types, depending on where they are installed:

- fittings for domestic sewage;

- for external sewer communication;

Helpful information! The first type includes products installed inside apartments and private houses, as well as other structures. The purpose of the internal sewer communication is the transportation of effluents to the external sewage system, which performs the function of their discharge to treatment facilities. Pipes and fittings of the external sewer system are mounted outdoors.

According to the connection method, two main types of fittings made of polyvinyl chloride are distinguished:

- by means of a rubber sealing element (gasket);

- with glue. In this case, docking is performed without the use of a sealing ring.

Almost all PVC fittings are typically mounted using a rubber seal. This allows you to achieve the required level of sealing compounds.

PVC fittings for domestic sewers

Consider a variety of polyvinyl chloride fittings for internal sewage, mounted using a rubber sealing element:

- compensation pipe. This product is used to repair sewer structures inside residential, industrial and other structures. The compensation pipe is mounted on the site of the cut out (broken) communication section. Its docking to the pipe is carried out by means of a connecting bell on one side, and on the other, with the help of another connecting element - a coupling. Such sewer pipes are considered very popular products and are equipped with rubber sealing elements;

- coupling. The connecting piece, which is made of PVC and is used for joining pipes on a flat section of the pipeline. There are two types of couplings for internal sewer communications: with emphasis, full bore (used during repair);

- reduction. This is a connecting part, which is used to organize transitions between pipes with different cross-sectional indicators. In addition, it is also used to connect pipes from different materials (for example, for joining PVC and cast iron);

- audit. It is equipped with a cover and is used if cleaning measures are planned;

- tee. A popular fitting that is used to connect an auxiliary branch to the main sewer line. The most popular tees, which have the following angles: 45, 90 °;

- a cross (with one or two planes). Connection piece for joining four pipes together. Sewer cross may have a different diameter of pipes, for joining pipes with different cross-sectional indicators;

- stub. It is used to clog a deaf section of sewer communication.

- challenge. This is a device that is used to branch the sewage system at a certain angle. Typically, these angles are 30, 35 and 90 °.

PVC fittings for outdoor sewage

For the external sewer network, the same fittings are used as for the internal one, however, there are some distinguishing features in their structure. Docking of such products is also performed by means of a rubber seal. So, we consider the types of fittings for external sewage and their features:

- challenge. An outlet for external sewage is characterized in that it has a greater variety of angles. With the help of such a connecting element, it is possible to arrange a pipe turn by: 15, 30, 45, 67, 90 °;

- two-bell branch. The product, each side of which is equipped with rubber sealing elements;

- coupling. In this case, it is represented by only one species;

- tee. It differs in that its angle is always 90 °. The tee for the external sewer network can be three-bell-shaped;

- a crosspiece (single-plane). It is always located at right angles, like a tee;

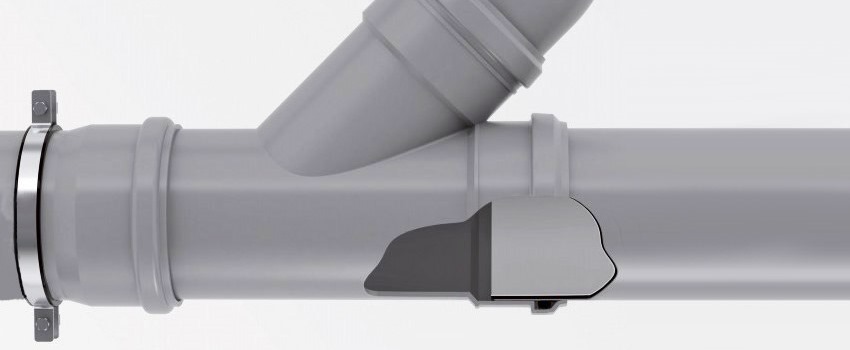

- check valve. Such a fitting is mounted on a horizontal sewer line, the slope of which does not exceed 2 centimeters per meter;

- two-knee siphon.

When installing an external sewage system, it is very important to choose the right connecting elements. This is necessary for the organization of branches and the implementation of the desired bias of the system.

Adhesive Mounted Fittings

Using glue, the following types of fittings are mounted:

- coupling;

- bend, with which you can organize the rotation of the system at 30, 45, 87, 90 °.

- a tee, which is mounted on glue and has rotation angles corresponding to that of a tee for an internal sewer structure;

Helpful information! Connecting products, which are installed by using a special adhesive, can be used for internal and external sewer communications.

- reduction;

- revisions;

- a cross (two-plane), which has angles of 45 and 90 °;

- glue plug;

- saddle. This is a special connecting device that is used for tapping into the main riser. This element can be equipped with a socket located at an angle of 90 °.

Installation of fittings with glue is considered a fairly simple event, however, the reliability of the sewer system without rubber sealing elements is not so high. Specialists recommend the use of rubber o-rings in combination with various sealants (preferably based on silicone) for the private installation of this communication.

Silicone sealant, although it has a rather high cost, is a popular tool that can provide the necessary sealing performance in sewer communication.

Features of installing PVC fittings for sewage

For proper installation of the sewer structure with your own hands, you need to familiarize yourself with the features of using individual elements, as well as with the installation rules. There are some useful tips that can help you avoid problems when building this communication. Consider them:

- PVC pipes must be cut with a special hacksaw (for metal). It is desirable that the teeth on the canvas are small. This is necessary in order to get the most even cut, without sticking out plastic pieces;

- after cutting the pipes into segments of the required size, it is recommended to process their ends. The ends should not have burrs, be rough. To do this, you can use sandpaper. The preparation of the ends will contribute to a denser shrinkage of the fitting. In addition, during operation, well-cleaned parts minimize the risk of leakage;

- the ends when stripping should not be wet;

Joints of pipes with fittings should not have any voids.If voids are present, it is recommended to treat them with a sealant to avoid leakage of the problem area during operation.

Consider the phased installation of the connecting fitting, which includes a rubber sealing ring:

- First of all, the connecting device must be cleaned from dust.

- Next, you need to make sure that the rubber o-ring is positioned correctly.

- At the third stage, it is recommended to use a marker. A marker will be needed in order to mark the depth on the PVC pipe to which the connecting element will be mounted.

- Then, silicone-based sealant must be applied to the inside of the fitting. It is recommended to carry out this work carefully, as the excess consumption of sealing material will affect financial costs.

- At the last stage, it is necessary to dock the sewer fitting with the pipe. Docking is performed according to the previously marked line marker.