One of the important operational requirements for sewage is its noiselessness. Cast iron pipes are thick-walled, heavy and absorb sound well. Modern communications made of polymeric materials with all their other advantages have a significant drawback - they need sound insulation. Sewer pipes are lightweight, their thin walls, being in resonance with the internal vibrations of sound, significantly increase the noise level.

Content

Types of noise in the sewer and the reasons for its appearance

The main reasons for the noise of sewer communications in the apartment:

- poor fastening of the riser and its remoteness from the walls;

- material features and low wall thickness of pipes;

- the interaction of air and water flows inside the pipe;

- runoff speed.

In the sewer system, such noise can occur: shock, resonance, atmospheric. Each of them is characterized by characteristic vibrations, which requires the use of soundproofing sewer pipes to ensure comfortable living conditions for a person.

The cause of the impact noise is poor mounting of the riser, which beats against a wall or an adjacent pipe. Resonant noise in the apartment occurs due to fluctuations in the entire sewer system during the movement of wastewater. This problem may be due to errors in installation during the laying of the pipeline, outdated communications, which over time have lost the strength characteristics. Atmospheric noise is created by air currents passing through the pipes and creating a vibration.

With your own hands, it is necessary to perform sound insulation of sewer pipes in the apartment after determining the causes and type of noise. For example, in the case of impact noise, it is sometimes sufficient to provide a more reliable pipe mount with clamps or auxiliary flanges. The source of the greatest noise is usually a sewer riser, the sound insulation of which should be carried out first.

Basic noise reduction techniques

Sound insulation of sewer pipes can be provided in the following ways:

- Apply silent pipes. Due to the thicker walls and a special structure, they make resonance impossible and, therefore, reduce the noise level.

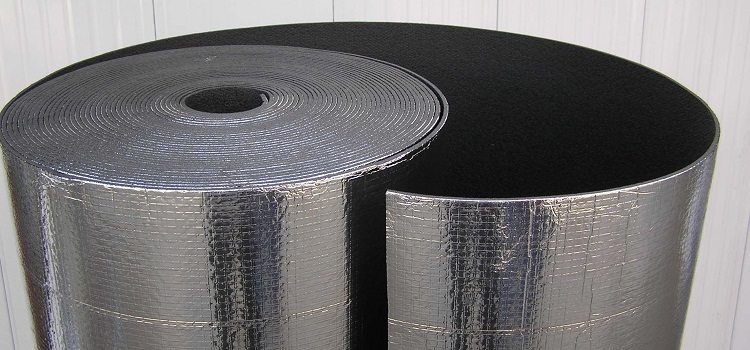

- Use isopropylene, porous rubber or foamed polyethylene for sound absorption.

- Isolate the riser using sound-absorbing coatings having a porous structure.

- Secure the pipes with mounting clamps having rubber inserts to prevent the propagation of sound waves.

- Carry out sound insulation with special materials (synthetic rolled, soundproof tapes, etc.).

Wrapping with these materials does not always look aesthetically pleasing. In this case, the placement of pipes in a box or other masking method is used. At the same time, the design must be collapsible, so that in case of leaks, repair work is quickly carried out.

If the pipes are fixed correctly, but there is still noise, you should wrap the riser with special material

The use of mounting foam for soundproofing sewer pipes is not recommended. This method will not give the desired effect and will create an obstacle in identifying damage and leakage of pipes.

Important! In practice, only noise reduction is possible, and not its complete elimination.

The use of soundproofing materials

Both for partial and complete soundproofing of sewer pipes in apartments, foam shell or polyurethane foam is used. This material is more expensive than some roll sound insulators, but allows you to quickly carry out work in hard to reach places and bends of the pipeline. Polyurethane foam can be in the form of a roll or mat of different thickness and width, a tubular release form is possible. Foam shell is applicable on straight sections of communications. When installed, its joint must pass through the pipe mount to the wall.

Foamed polyethylene, in addition to good sound-absorbing properties, prevents the formation of condensate on the pipes, which protects them from the appearance of fungus and mold. Its shortcoming is fragility. You can use a special soundproof tape that wraps as tightly as possible around the pipe. Roll materials are widely used, but their characteristics are sensitive to environmental influences and air spaces should not arise when wrapping them between layers.

The packaging of soundproofing materials provides information on the level of noise (in dB) that it can absorb. The higher this value, the better the effect. In order for the material to last longer, it is necessary to choose a coating with the most rigid outer layer.

How to carry out sound insulation work

Soundproofing sewer pipes in the apartment can be done by yourself. It is necessary to cut off a strip of soundproofing material equal to the circumference of the pipe. Wrap it in a sewer riser. Noise isolation will be more effective if the edges touch butt. Mounting is carried out with construction tape. It is better to wrap the pipe in several layers, which will increase its mass, reduce resonance and thereby reduce the noise level.

When carrying out noise insulation of sewer pipes with their own hands, to increase efficiency, it is necessary:

- choose the right material for noise insulation of sewer pipes;

- monitor the tightening of plastic fasteners, wire or tape on soundproofing material;

- place a sealing gasket or foamed polyethylene when installing the riser in the ceiling;

- lay soundproofing material in a thick layer;

- plastic fasteners should be placed at a distance of 200-250 mm from each other.

If it is decided to use screeds, it is better to choose reusable ones or stock them, so that in case of pipe repairs, quickly install the insulation again.

If clamps are used as fasteners, then rubber pads should be installed under them.

Important! Sound insulation with mounting foam is unacceptable, since it conducts sound very well after solidification.

Features of using silent pipes

The silent pipe is a heavy-duty, homogeneous, three-layer construction. Soundproofing the sewer riser in the apartment is provided by the structure of the pipe without the use of additional materials.

The inner layer of polypropylene has a smooth surface, which creates conditions for good passability of wastewater. It is resistant to aggressive chemicals and high water temperatures, prevents the appearance of corrosion. The intermediate layer due to special mineral inclusions provides sound insulation of the sewer pipe. The heavy-duty polymer material of the outer layer protects against external mechanical influences.The procedure for installing silent pipes with your own hands is as follows:

- Make the necessary calculations, cut off the pipe according to the dimensions obtained and clean the edges with a file.

- Place o-rings.

- To clear an internal and external surface of a pipe of dirt or other substances.

- Apply silicone to the pipe fittings and push the bell all the way onto it.

- Pull the pipe back 10 mm, which is necessary to compensate for the length of the pipe, which may change under the influence of different temperatures.

- Install the pipe vertically, attach to the wall, floor, ceiling.

Such pipes to the wall also need to be fixed securely so that the sound insulation is maximum.

The use of silent pipes will increase the cost of laying or replacing communicationsbut will provide sound insulation of the sewer riser.

Helpful advice! It is better to clean the cut edges of the pipe at an angle of 150 °. This will prevent the o-rings from breaking.

Sewer pipe and infrasound

In the sewer system, sound waves of such a frequency can occur that the human hearing does not perceive - infrasound. Such fluctuations appear during the formation of plaque or growths inside the pipe during prolonged use. Infrasound is harmful to health. Do-it-yourself sound insulation for infrasound for sewer pipes can be implemented in two ways:

- partial replacement of the riser;

- damping a whole plastic riser.

In the first option, parts of the cast-iron pipe remain together with crosspieces, and the middle part is sawn off and removed. Using special cleaning agents, plaque is removed inside. In place of pig-iron with the help of fasteners and adapters, a pipe made of polymer materials is mounted and soundproofed. Since the plastic pipe is divided into parts no longer than 5 m, the spectral picture of the sound changes and it is suppressed.

The second option is similar, but in this case, the entire riser changes from floor to floor. The soundproofing of the plastic sewer pipe from the walls is made by clamps, from the floors - part of the polyethylene pipe with a large diameter and polyurethane foam filler.

Thus, the nature of sound vibrations indicates the cause of the noise. A variety of solutions to the problem allows you to independently carry out work on sound insulation.