When laying a home water supply or heating system, a reasonable question often arises: how to bend a metal-plastic pipe at home. You can get a high-quality result even without special skills and knowledge. For effective bending of metal-plastic constructions, there are several methods, each of which has its own advantages and features.

Content

How to bend a plastic pipe: basic methods

Almost in every plan of the pipeline there are bends and turns. Therefore, the technology of bending metal pipes is used very often. If you try to give the pipe the desired shape, not knowing its characteristics, you can spoil the product. Fragile metal-plastic walls can deform or crack.

If necessary, bending a metal-plastic pipe at home uses several methods.

Manual pipe bending. The most affordable method of bending metal pipes that does not require the use of tools. You can bend with your hands a structure whose diameter does not exceed 20 mm. Large diameter pipes are difficult to bend by hand. Despite the speed, this method can be called the most unreliable. Is it possible to bend metal-plastic pipes in this way without violating their structure is a matter of practice, but without certain experience there is too much chance of violating the integrity of the material.

Springs for bending metal pipes. This method is optimal for structures made of medium hard plastic. Springs for bending metal-plastic pipes, provided that the diameter is correctly selected, allow for high bending accuracy. This will require a sufficiently strong spring, not amenable to deformation. A wire of length sufficient to remove the spring after bending is attached to one of its ends.

A spring is pushed along the inside of the pipe to the place where the bend is planned. It is important to ensure that the centers of the spring and the future bend match exactly. The product bends smoothly at the desired angle, while you can emphasize the knee. Upon completion of bending, the spring is removed.

Rigid wire for bending metal pipes. The process of bending by wire is longer, but also quite effective. The wire is cut into small pieces, which should fill all the voids of the pipe at the bend. A layer of wire will serve as a frame that prevents the appearance of bumps and breaks. Further, the pipe bends in the same way as in the case of the spring. Used wire is carefully removed from the structure. It is also necessary to check if there are any pieces remaining in the pipe.

Sand application. One of the most time consuming ways to bend. It is often used in cases where it was not possible to find the required spring size. Fine sifted sand is poured into the pipe part so that there are no empty spaces in the pipe.Plugs are put on both ends of the pipe to prevent sand from spilling out. The product is clamped in a vice in a place far enough from the intended bend. Before bending, the pipe section is heated with a blowtorch.

Helpful advice! There is a danger of overheating the pipe, so the degree of sand heating should be checked. To do this, bring a sheet of paper to the heating site. If the paper begins to char, then the sand is quite calcined.

After giving the product the desired shape, sand spills out. If necessary, the pipe can be flushed. Instead of sand, salt can also be used.

How to bend plastic pipes with a pipe bender

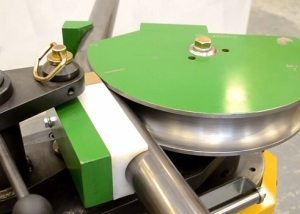

A pipe bender (Volnov's machine) is a device thanks to which it is possible to easily bend a metal-plastic pipe at home. Pipe bender allow bending structures without preheating, the bending radius can reach 180 degrees. Bending metal-plastic products using a pipe bender is completely safe, while completely eliminating the possibility of defective parts. Volnov's hand-held machine has a simple design. It consists of a handle, a movable roller, a template roller, a bracket and a bent pipe. Using this device is very simple, you can even make it yourself.

At home, crossbow or spring pipe benders are most often used. It is better to lightly grease the surface to which the pipe will bend before starting work. This will reduce friction between parts, and the pipe surface will not be damaged.

Helpful advice! An analog of a pipe bender can be made at home. It will consist of boards sawn in a semicircle pattern. Such a pipe bender must be tightly fixed on the base. It is important that the thickness of the board exceeds the diameter of the pipe.

More modern pipe benders are available for sale, such as hydraulic or electromechanical. On the farm, a pipe bender can be useful only for its intended purpose, that is, during the repair or installation of the pipeline. Therefore, the purchase of expensive models makes sense only if there is a very large amount of work to be done or if such work will be permanent.

The calculation of the bending radius of the plastic pipe

There is a universal formula for calculating the bending radius of a metal-plastic construction. According to this formula, the bending radius will be 5 pipe diameters. The principle of operation of this rule can be visualized using the example of a pipe with a diameter of 20 mm:

- For subsequent calculations, you need to determine a quarter of the circle. If the specified diameter is 20 mm, then the radius, according to the formula, is 100 mm (20 x 5 = 100).

- The starting points for bending the angle are calculated. The formula C = 2ΠR / 4 is used, where C is the size of the site on which work will be performed; Π = 3.14; and R is the radius obtained above. Substituting your own data, the following is obtained: 2 * 3.14 * 100 mm / 4 = 157 mm. So, a section of pipe with a length of 157 mm will be involved in bending.

- It turns out that every 10-20 mm is about 15 degrees from the total bend. On the surface of the pipe, the boundary of the section is marked with a pencil. Now you can start any method of bending.

Bending metal pipes at home: tips and tricks

Before starting work, it is worth making several test bends on the sample. This will help determine the desired pressure, choose a convenient position and method of bending. But no matter how the bending method is chosen, strong pressure and kinks cannot be allowed. A perfectly smooth bend will not work out with a sharp movement.

Plastic pipes different brands and manufacturers will have varying degrees of rigidity. Accordingly, they will also bend in different ways.If there is no experience in using metal-plastic products, you can purchase several segments for training. In order for the pipe to hold the desired shape, you can bend it to a sharper angle, and then bend it to the desired one. So the design will be securely fixed.

All the technologies for bending metal-plastic pipes described above are time-tested and are actively used in the construction industry. There is nothing technically complicated in creating an even bend in a pipe that does not interfere with the functioning of the system. The main thing is to follow the instructions and act as carefully as possible.