Homework masters often face the need to reconfigure, in other words, bend the pipe to a given size. Then many people recall the existence of such a tool as a manual pipe bender for a round pipe, which you can not only buy, but also assemble with your own hands. Moreover, the second option is preferable, since there is a lot of similar equipment of factory execution.

Content

Device relevance

The use of pipe benders for a round pipe is not limited to plumbing. And if to be completely accurate, the pipes are bent when they are carried out infrequently. Fittings and bends are used to change the route of laying engineering communications. The latter are pipe sections bent in the factory, characterized by a standard set of parameters with the following restrictions:

- number of rotation angles. In addition to the direct, there are 180˚, 60˚, 45˚;

- bending radii (1.5 and 1 Du);

- connection method - welding.

But sometimes other radii and bending angles are required, and welding can not always be used. In this case, a manual pipe bender for a round pipe is definitely not enough.

Owners of cottages and private houses are engaged in bending pipes for other reasons. Indeed, the farm may have non-standard forms of greenhouses, arched structures for grapes, showers, fences, etc. The design of these objects is formed by cold-rolled round, and often profile products, so this equipment is also useful here.

At the same time, even many professionals prefer to work with a do-it-yourself pipe bender for a round pipe. After all, a home-made device is usually developed taking into account the anthropometric features and professional skills of its future owner. This factor increases the usability of the pipe bender, which, in turn, contributes to the quality of work.

Device classification

To subdivide such devices into groups, experts use several criteria. The main ones include:

1. Drive - manual, electric, hydraulic.

2. Installation - stationary and portable.

3. The method of exposure. There are several of them:

- winding. Where the death will begin, there is an emphasis. The pipe is clamped to the pipe bender roller (movable template). While rotating, the roller stretches it between the stop and itself (the template and the pipe are movable);

- running in. The pattern is motionless. The end of the pipe is clamped. Moving, the pressure roller bends it around the template;

- crossbow method (impact by stock). The pipe rests on two stationary rollers. The template on the stem presses the pipe in the center, and bends it between the stops;

- rolling (rolling). One central and two supporting, located in one line, rotating rollers are used. The location of these parts in relation to each other determines the radius of bending. Most often, the central roller presses the pipe.

Helpful information! The disadvantage of the first three methods is that the bending radius in them is specified by the template.

The implementation of a winding method using a homemade pipe bender for a round pipe is rare. More often it is used in industrial designs. The following drawback is inherent in the crossbow method: almost all the pressure created by the rod is transferred to the pipe where the top point of the template is located. At this point, the steel is most susceptible to tension, due to which the wall weakens, which is accompanied by a loss of shape up to its rupture, if the pipe is thin-walled. The latter method is practically devoid of disadvantages. Steel bends are produced in industrial conditions by rolling.

Rolling is the best way to bend pipes, with this method the risk of deformation or rupture of the metal is minimal

What professionals recommend

Before you start making a pipe bender with your own hands, choosing a specific model, you should take into account general recommendations regarding the bending radii of a steel pipe. They are presented in table No. 1.

Table 1

| Outer diameter of the pipe, D, mm | Bending radius (smallest) at wall thickness | |

| Over 2 mm | Up to 2 mm | |

| 60≤D≤140 | 5D | ———- |

| 35≤D≤60 | 4D | ———- |

| 20≤D≤35 | 3D | 5D |

| 5≤D≤20 | 3D | 4D |

The data presented in this table should be considered as optimal for specific sections of steel tubular products. But this does not mean that it is impossible to reduce the radius. However, in order to ensure the required quality of bending, it will be necessary to use a mandrel, and this is more difficult from a technical point of view. In addition to the mandrel, hot rolling is used in the factory.

In case if pipe bender completely made of metal, and its frame includes a fixed bed, then hot rolling is possible in the home workshop with your own hands. To do this, use a gas burner or blowtorch.

Homemade pipe bending tools

The low cost of such devices is determined by the fact that you can create a structure using used spare parts from various equipment and improvised materials. Moreover, in some cases, for the manufacture of a pipe bender for a round pipe, do-it-yourself drawings may not be required at all. The best illustration of this thesis will be the following example of a manual type device.

Its basis is a concrete slab. Holes are drilled in it, into which one inch metal pins are driven in (we are talking about their diameter).

Important! The distance of adjacent elements from each other should not exceed 50 cm.

Having fixed one end of the pipe between the pins, you can proceed to manual bending, putting pressure on its other end. After gaining the required form, leave it in a tense state. And so that the product does not return to its original state, pass through the metal pin into both opposite holes and weld a temporary jumper to them.

Everything is intuitive and, as we see, a drawing was not required to make a homemade pipe bender for a round pipe. Of course, the most primitive construction is described above. With your own hands you can create more complex products. Let us briefly dwell on some of them.

The simplest template manual pipe bender

The method is running-in. The material is wood. The drive is manual.

A template is made of wood. In the drawing and in real execution, its shape should correspond to the required bending radius, and the thickness should exceed the diameter of the pipe. The convenience of the work will contribute to the profiling of the end face of the template. You can create the necessary profile using 2 boards with a cut line, beveled inward.

The template is attached to a fixed base. From one side, a stop is screwed to the same base and a pipe is applied. If the lever is insufficient, you can increase it with a piece of reinforcement. Bend slowly so as not to allow the pipe to slide off the template.

It is also impossible to classify such home-made hand tools as high-tech equipment. However, he also has the right to life, especially if it is necessary to bend a pipe with a large bending diameter with his own hands at the lowest cost.

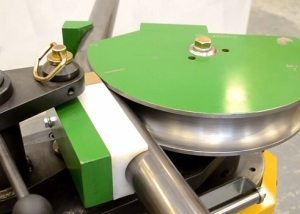

Steel break-in pipe bender

Among home-made devices, such a device is most widely used. Used billets from the engine are used as blanks. However, some home craftsmen order such parts from a familiar turner or dial from washers with different diameters. And in this case, you can do without the drawing of a pipe bender for a round pipe, but it's better to do it all the same. At least in order to indicate to the turner the dimensions of the required part.

A self-made steel break-in pipe bender can be seen in the garage or shed of almost every masterful owner of the house. Devices of this type are suitable for working with plumbing pipes of all running sizes. The lever can be strengthened by lengthening it to any reasonable extent.

Manual winding machine.

It is similar in design to the previous product. However, the winding pipe bender provides the ability to bend the workpiece into a ring. Using other adaptation options makes this difficult. You can easily find the drawing of the device on the World Wide Web. When studying it, pay attention to the fact that the cheeks of the template pulley are removable. This design allows you to pull the workpiece closed in a circle.

Helpful information! For the manufacture of a winding machine with your own hands, in principle, you can use any material, from wood to metal and textolite.

Features of manufacturing a hydraulic pipe bender for a round pipe

If you need a more serious device for professional work, it is better to build a hydraulic pipe bender with your own hands. The strength of the hydraulic jack included in its design will allow to avoid significant physical labor.

Forming the drawing of such a device, it is necessary to take into account that the best option for the manufacture of sidewalls is a thick rod with a diameter of 18-20 millimeters and a corner with a side width of 25 millimeters. In addition, to make these elements, you will need 10 mm thick sheet metal. Holes for mounting eccentric supports will be drilled in these plates.

The support is a tube of a suitable size. A bolt of 18 millimeters is welded into it. Also in the drawing, show that there is a semicircular hole in the middle of the support. The workpiece bent during operation of a manual hydraulic pipe bender will abut against it.

To make a punch, a sheet of metal 4 mm thick is used. Two semi-circles in the form of blanks are cut from the plate. The radius of each of them should be equal to the estimated radius of the pipe bend. Then the pipe with a diameter of 32 mm is cut in half and one of the halves is bent in accordance with the preforms prepared at the previous stage, after which the pipe and plates are welded. For reliability, so that during operation of the hydraulic pipe bender the punch does not crush, jumpers are welded inside. This will ensure structural rigidity.

A tube is welded into the center of the bed. It will serve as a stop for a drive made of a hydraulic jack. All these features should be displayed on a preliminary drawing of the designed device. So you can create a set of necessary materials with the given sizes, and in the absence of some items, order parts for a hydraulic pipe bender from a familiar milling machine operator and turner.

Based on the foregoing, we can say that there are many options for how to make equipment for bending pipes.The main thing is the availability of tools and desire.