The presence in the country house of centralized water supply solves many problems associated with providing residents with drinking water. If it is not there, a well usually acts as a source today. Its depth is determined by the characteristics of the site, in particular the remoteness of the aquifer from the earth's surface. But for the durability of the system and the quality of the water is largely responsible for the well filter for the applied variety of casing pipes.

Content

Device and filter types

Currently, there are 4 options for systems that purify water from solid impurities:

- wire;

- holey;

- slotted;

- gravel.

Homemade devices have the following requirements:

- the materials used must comply with the sanitary standards in force in our country;

- corrosion resistance;

- compact with high bandwidth.

The design of a conventional filter on a pipe for a well includes only three main parts:

- filter element. It prevents sand, fine gravel, silt and debris from entering the water supply pipe. The simplest filter element is a regular grid;

- sedimentation tank. Penetrated rock particles accumulate here;

- superfilter section. Performs the function of the fastening element to the pipe. If a plastic pipe is used to manufacture the filter, there is no need for a filter section.

The water produced by the new well must be returned for analysis to a specialized sanitary facility. You can use it for domestic purposes upon receipt of appropriate confirmation. But only boiled water is allowed.

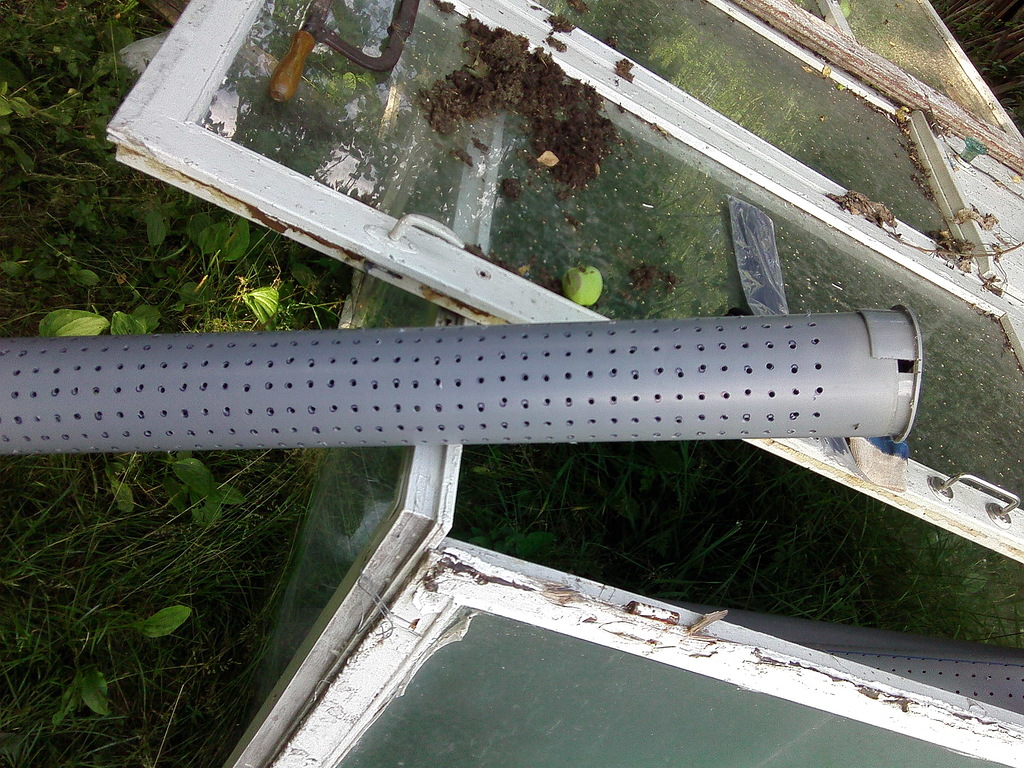

Making a hole filter for a well from a plastic pipe

This design, filtering water from the well, is most widespread. Time-tested performance, ease of manufacture and low cost are its main advantages.

For work, prepare:

- hand drill;

- a piece of metal mesh;

- a wooden stub;

- chalk for marking;

- a plastic pipe of a suitable diameter.

Advice! Select the diameter of the drill, taking into account the characteristics of the soil, in particular taking into account the granulometric composition of the rock.

Work on the manufacture of a hole filter is performed in the following sequence:

- With the plastic pipe horizontal, mark it out. At the same time, the requirement that the perforation is applied to the fourth part of the pipe located directly in the water intake zone must be fulfilled. The first row of holes is planned at a distance of 10 centimeters from its edge, and the distance of the holes from each other should be 1-2 centimeters. They should be arranged in a checkerboard or linear order;

- drill holes. This must be done in accordance with a specific technology. Position the drill bit relative to the surface of the pipe at an angle between 30 ... 60˚. And drill holes from bottom to top.Upon completion, remove the chips by tapping the pipe;

- to prevent clogging of holes during operation, wrap the device with a special mesh;

- close the bottom of the pipe with a wood plug. It will reliably separate the filter element from the casing shoe.

Casing Slit Filter Production

A device of this type is nothing more than a casing plastic pipe with crevice perforation. In addition to performing its main function - to prevent the penetration of particles of soil and debris into the cavity of the water column, the filter will additionally strengthen the shaft of the shaft from collapse.

Well productivity depends on how freely water will flow through the grooves cut in the pipe. If we compare two such sources, the water loss will be greater for the one whose working surface is larger.

Before starting work, measure the length of the sump. The value of this parameter usually ranges from one to one and a half meters and is the value of the derivative of the depth of the well.

To make a slotted type filter for casing, you will need:

- cutting tool (hacksaw or grinder);

- stainless steel or brass mesh;

- pencil or chalk for marking;

- piece of plastic pipe.

Operating procedure:

- markup. Put with chalk the places where the cracks will be located. You can cut them over each other or in a checkerboard pattern;

- slotting. The width of the cut depends on the thickness of the cutting tool, while its length should be 2.5 - 7.5 centimeters. So that the pipe does not lose the ringstiffness, leave areas without cuts on it. Then they will be installed reinforcing belt;

- fastening of a protective grid. Wrap the pipe first with a 3 mm stainless wire. Apply spirals at a distance of about 20 centimeters from each other. Every 50 centimeters, the winding is soldered pointwise. Then the lap is wound around the grid and fixed with wire (the inter-turn distance is 5-10 centimeters). Each turn is soldered or fastened with pliers.

Note! To choose the right grid, it is necessary to find out what sizes are characteristic of soil particles. To do this, pour a handful of sand taken from the well on a graph paper and estimate the size of the grains of sand. Choose a grid based on the data. It can be square or galloon weaving.

The experience of professionals shows that for gravel soil a square weave network is preferable. At the same time, the best indicators of strength and permeability are inherent in the brass grid of brass weaving.

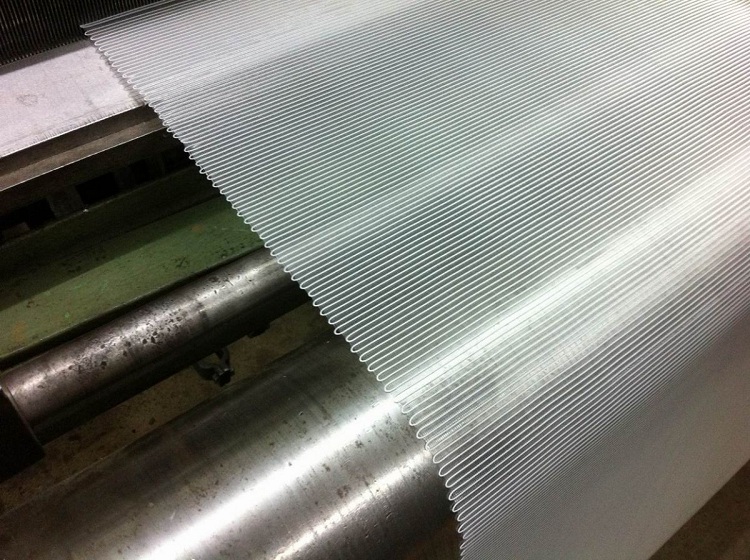

Manufacturing a wire filter system

Such designs are characterized by increased strength, and compared with previous versions, they also have a longer service life. They are arranged quite simply: perforated pipe, wire winding and protective mesh. To create a wire filter, perform the following sequence of operations:

- make the primary slit filter;

- solder the longitudinal stiffeners. For this purpose use stainless steel rods with a diameter of 5 millimeters;

- wrap the resulting base with stainless steel wire with a cross section of 2.5 mm.

It would seem that everything is quite simple. However, a violation of technology, such as errors in winding or poor soldering, will cause malfunctions. Therefore, it is recommended to buy a wire nozzle ready. Combining it with the main one is easy.

If filter removal is necessary

It is immediately necessary to warn that it is possible to dismantle the filter only if two columns are installed in the well: production and filter. In this case, it is only necessary to extract the second.For this purpose, you can attract professionals. But at the same time, one must be prepared for significant material costs to pay for their work. If the family budget does not allow you to use the services of drillers, do the following sequence of events:

- lock the end of the pipe. To do this, use a special clamp for casing and hinges;

- fasten the latch on the short shoulder of the pre-selected long lever. Having done this, you can begin to pull out the pipe;

- then disconnect the destroyed filter and install a new one;

- then drill again at the installation site of the filter column. This should be done using a clay solution as protection. Finally, install the filter column.

As you know, this product can be made of various materials. In order to dismantle the plastic structure, it is recommended to use a crimp clamp for casing.

And since you started to modify the design of the well, you know - this is a great opportunity to mount the adapter on the casing. With this device, sections of the water pipe are discharged directly through the casing pipe. A feature of the adapter is that it allows you to display the elements of the water supply system below the freezing point of the soil. At the same time, the tightness of the structure is guaranteed.