Polymeric materials have long strengthened their positions in all areas of activity. For many decades, they have found new niches of application due to their versatility. The first of these is polyvinyl chloride, a polymer whose annual worldwide consumption today amounts to 30 million tons.

What is NPVC?

In the process of polymerization of vinyl chloride, for the production of which raw materials are used from petroleum products and sodium chloride (sodium chloride), PVC is obtained. If you make some modifications to the technology for manufacturing a PVC product, you can get a polymer with completely different qualities. So, excluding plasticizers from the composition, they produce hard, durable PVC or unplasticized polyvinyl chloride (NPVC, RPVC, PVC-U) - a safe plastic that is best suited for the production of drinking water supply and sewage pipes.

The NPVH pipe during its existence has been thoroughly investigated under normal conditions of use as directed. The final result was practical indicators of the stability of characteristics over a 50-year period. Trust was the result of continuous use of PVC-U pipes in the construction of pressure / pressureless systems.

Externally, the pipes differ in size (diameter, wall thickness, length), color and the presence of a bell. It all depends on the destination. Gray color is usually for internal systems, orange (brown) for outdoor, blue and white casing pipes for wells are also found.

Plasticizers are not used in the manufacture of PVC-U pipes, therefore, such products are more rigid than conventional polyvinyl chloride

Household and industrial applications

The most common application examples are:

- construction of water intake systems while drilling autonomous artesian wells. It uses a casing NPVH pipe equipped with a bell-shaped threaded pipe-to-pipe connection, so that it can be installed in the ground to a depth of 300 meters;

- design of a cold water system;

- construction of internal and external sewage of gravity and pressure type with laying in the ground to a depth of 1-8 m;

- design of a technical pipeline with transportation of various media, the temperature of which is not higher than 45aboutWITH;

- drainage, drainage and storm drainage;

- construction of irrigation systems in agriculture;

- power cable protection;

- repair of plumbing and sewer systems from other materials (replacement of a part of a metal pipeline).

Performance characteristics of NPVC pipes:

- smooth external and internal surfaces provide constant high throughput, resistance to abrasion, wear, overgrowing, bacterial reproduction;

- stiffness, strength, endurance to the tested external (160 atm) and internal pressure (6.3-25 bar), hydraulic shock, shock loads;

- complete absence of corrosion, chemical neutrality to alkalis, acids, salt solutions, alcohols, industrial gases, fat, gasoline and other aggressive environments. Do not affect the taste, color and aroma properties of the liquids in the food industry (juices, vegetable oils);

- do not support combustion (have self-extinguishing up to a limit of 450aboutC), operating temperature from -50aboutC to 78aboutC, fluidity occurs at 180aboutC, thermal conductivity is low;

- light weight (however, it does not float in the water, which is important when a large amount of water comes into the well), bio / environmental safety, and a service life of 50 years or more.

Important! PVC dissolves in contact with acetone, dichloroethane, chlorine / nitrobenzene.

The narrow limits of the operating temperature range somewhat limit the NPVC pipe in use. So, in conditions below -50aboutSince it becomes fragile, therefore, it is advisable to warm it, the temperature of the conducted substance should not exceed 45aboutC (90aboutC withstands no longer than 1 minute), installation should not be done in a space with a temperature below -10aboutWITH.

The dimensions of the NPVC pipes and the presence of the socket depend on their purpose. For internal non-pressure networks (gray color of the products) there is a diameter of 32-110 mm with a wall thickness of 1.5-3.5 mm and 4-8 mm for systems with pressure. For external networks (orange, brown), pipes with a diameter of 90-1000 mm with a wall thickness of 5.5-30 mm are used, designed to work in pressure conditions. The length of the products is from 300 mm to 2000 mm (internal), from 500 mm to 6000 mm (external).

The table shows the dimensional grid of the NPVC pipes relative to the working pressure, where SDR is the standard size ratio of the outer diameter to the wall thickness.

Table 1

| Outer diameter mm | Wall thickness, mm at PN (nominal pressure), bar | ||||||

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.7 | SDR11 | |

| PN6 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | |

| 12,0 | 1,51 | ||||||

| 16,0 | 1,51 | ||||||

| 20,0 | 1,51 | 1,91 | |||||

| 25,0 | 1,51 | 1,91 | 2,31 | ||||

| 32,0 | 1,51 | 1,61 | 1,91 | 2,41 | 2,91 | ||

| 40,0 | 1,51 | 1,61 | 1,91 | 2,41 | 2,99 | 3,71 | |

| 50,0 | 1,61 | 1,99 | 2,41 | 2,99 | 3,71 | 4,61 | |

| 63,0 | 1,99 | 2,51 | 2,99 | 3,81 | 4,71 | 5,81 | |

| 75,0 | 2,31 | 2,91 | 3,61 | 4,51 | 5,61 | 6,81 | |

| 90,0 | 2,81 | 3,51 | 4,31 | 5,41 | 6,71 | 8,21 | |

| PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 | |

| 110,0 | 2,72 | 3,39 | 4,21 | 5,31 | 6,59 | 8,11 | 10,1 |

| 125,0 | 3,11 | 3,92 | 4,81 | 5,99 | 7,42 | 9,21 | 11,41 |

| 140,0 | 3,52 | 4,31 | 5,42 | 6,71 | 8,31 | 10,31 | 12,71 |

| 160,0 | 3,99 | 4,89 | 6,19 | 7,72 | 9,52 | 11,81 | 14,61 |

| 180,0 | 4,41 | 5,51 | 6,92 | 8,61 | 10,71 | 13,29 | 16,41 |

| 200,0 | 4,98 | 6,23 | 7,71 | 9,62 | 11,89 | 14,71 | 18,21 |

| 225,0 | 5,51 | 6,95 | 8,61 | 10,79 | 13,41 | 16,59 | |

| 250,0 | 6,22 | 7,71 | 9,62 | 11,91 | 14,99 | 18,42 | |

| 280,0 | 6,95 | 8,61 | 10,71 | 13,42 | 16,92 | 20,61 | |

| 315,0 | 7,71 | 9,72 | 12,11 | 14,99 | 19,11 | 23,21 | |

| 355,0 | 8,72 | 10,93 | 13,61 | 16,91 | 21,52 | 26,12 | |

| 400,0 | 9,83 | 12,31 | 15,32 | 19,11 | 23,98 | 29,39 | |

| 450,0 | 10,99 | 13,82 | 17,02 | 21,51 | 26,71 | 33,11 | |

| 500,0 | 12,31 | 15,31 | 19,11 | 23,89 | 29,99 | 36,79 | |

| 560,0 | 13,74 | 17,23 | 21,41 | 26,71 | |||

| 630,0 | 15,41 | 19,32 | 24,12 | 29,99 | |||

| 710,0 | 17,42 | 21,81 | 27,21 | ||||

| 800,0 | 19,61 | 24,51 | 30,62 | ||||

| 900,0 | 21,99 | 27,62 | |||||

| 1000,0 | 24,51 | 30,60 | |||||

Important! The lower the SDR, the higher the pipe strength.

Marking is applied to the surface of the product, includes:

- product material (NPVH, PVC-U);

- the presence of a bell;

- size (nominal diameter and wall thickness);

- destination;

- technical conditions;

- the date.

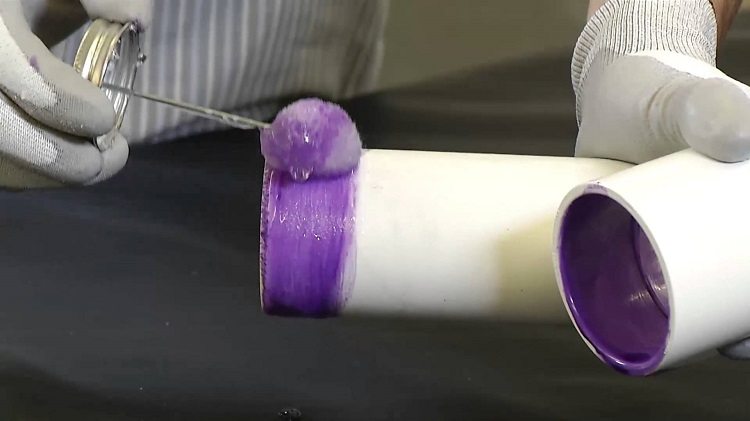

An important advantage of NPVC pipes is the ease of installation - they can simply be “planted” on special glue

The installation of the pipes does not cause difficulties due to its light weight and simple connection methods, which can be threaded (casing, flange), using a rubber ring-seal (gravity drainage), adhesive, fitting (using special fittings that are seamlessly joined by soldering). All types of docking are simple, airtight and do not require energy. In the event of damage to the pipeline, everything is designed for quick repair, as it is possible to replace the defective area using docking repair parts.

The main distinguishing feature of NPVC pipes is the stiffness of the material, which allows them to be laid deep in the ground without the risk of deformation from loads. Bookmark Depth should be below the level of freezing of the soil, otherwise they should be insulated.

Experiencing pressure inside and out, the pipeline will function perfectly for many years without major repairs. The decisive factors here will be: the correct selection of high-quality pipes, professional installation and operation under normal conditions.