No construction is complete without water and gas pipes. Water supply is necessary in production, in agriculture and in residential buildings. The main advantage of steel products is the possibility of laying them in an open area, which can not be said about plastic pipes. Those can be used only in certain areas: communication inside the building, pressureless sewage, local water supply.

Advantages and disadvantages

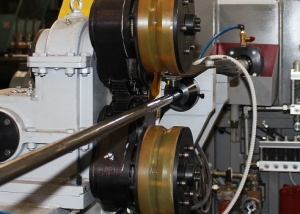

Water and gas pipes are produced by molding from steel billets - strips. The edges of the workpiece are welded with a reinforced seam, which undergoes a quality control procedure. GOST 3262 75 states that for this it is necessary to use radiography.

These products are made, as a rule, straight-seam, since resistance to external loads is not so important for them as resistance to internal pressure.

Of the advantages of a water and gas pipe GOST 3262 75, experts distinguish:

- low coefficient of expansion;

- gas, including oxygen, impermeability;

- high strength. This property allows the installation of water and gas pipes GOST 3262 75 in any areas and by any suitable method;

- affordable cost;

- durability. With proper maintenance, the steel water pipe will last 50 years.

The disadvantages include:

- relatively considerable weight. Because of this, installation is difficult and requires a large number of fasteners;

- metal accumulates electricity. Static stress relief is carried out by regular preventive maintenance;

- the need for thermal insulation of steel water and gas pipes GOST 3262 75 when laying them in the ground. The expansion of the freezing liquid with constant product parameters can cause damage to them up to ruptures.

Specifications

Water and gas pipes are used in the construction of residential private and apartment buildings, industrial facilities, educational institutions, office buildings and other facilities. They are used to organize:

- gas pipeline;

- cold and hot water supply systems;

- heating.

Important! Hot water supply is based on welded pipes with thick walls. For cold, products with average indicators are suitable.

The footage of steel welded water and gas pipes GOST 3262 75 is as follows:

- measured length 4 ≤ L ≤ 8 or 8 ≤ L ≤ 12 meters;

- unmeasured lengths of length 4 ≤ L ≤ 12 meters.

According to the parameters of the wall, this type of pipe is conventionally divided into the following groups:

- ordinary;

- reinforced;

- lungs.

Tables No. 1-3 show the metric data of the products of each of these groups. The ratio of the mass and size of the pipes depends on the steel grade, wall thickness, diameter and the processing method of the material (non-galvanized, galvanized).

Table 1 presents the dimensions and weight of ordinary steel water and gas pipes GOST 3262

Table 1

| Nominal bore, DN, mm | Weight per meter, kg | Outer diameter, days, mm | Wall / board thickness, S, mm | The number of meters in one ton, Nt, m |

| 150 | 17,81 | 165 | 4,5 | 56,14 |

| 125 | 15,04 | 140 | 4,5 | 66,5 |

| 100 | 12,15 | 114 | 4,5 | 82,29 |

| 90 | 9,6 | 101,3 | 4,0 | 104,2 |

| 80 | 8,34 | 88,50 | 4,0 | 120 |

| 65 | 7,05 | 75,50 | 4,0 | 141,8 |

| 50 | 4,88 | 60 | 3,5 | 205,1 |

| 40 | 3,84 | 48 | 3,5 | 260,4 |

| 32 | 3,09 | 42,3 | 3,2 | 324,1 |

| 25 | 2,39 | 33,5 | 3,2 | 418,2 |

| 20 | 1,66 | 26,80 | 2,8 | 603,4 |

| 20 | —— | 26,8 | —— | —— |

| 15 | 1,28 | 21,30 | 2,8 | 782 |

| 15 | —— | 21,3 | —— | —— |

| 10 | 0,8 | 17 | 2.2 | 1245 |

| 8 | 0,61 | 13,50 | 2,2 | 1631 |

| 6 | 0,4 | 10,2 | 2,0 | 2473 |

Table 2 presents the parameters of steel reinforced welded water and gas pipes of GOST 3262 75.

table 2

| Nominal bore, DN, mm | Weight per meter, kg. | Outer Diameter, Days, mm | Wall / board thickness, S, mm. | The number of meters in one ton, Nt, m |

| 150 | 21,63 | 165 | 5,5 | 46,22 |

| 125 | 18,24 | 140 | 5,5 | 54,81 |

| 100 | 13,44 | 114 | 5 | 74,41 |

| 90 | 10,74 | 101,3 | 4,5 | 93,03 |

| 80 | 9,32 | 88,5 | 4,5 | 107,3 |

| 65 | 7,88 | 75,5 | 4.5 | 126,9 |

| 50 | 6,16 | 60 | 4,5 | 162, |

| 40 | 4,34 | 48 | 4 | 230,4 |

| 32 | 3,78 | 42,3 | 4 | 264,7 |

| 25 | 2,91 | 33,5 | 4 | 343,6 |

| 20 | 1,86 | 26,80 | 3,2 | 536,9 |

| 20 | —— | 26,8 | ——- | —— |

| 15 | 1,43 | 21,30 | 3,2 | 700,1 |

| 15 | —— | 21,3 | ——- | —— |

| 10 | 0,98 | 17 | 2,8 | 1020 |

| 8 | 0,74 | 13,50 | 2,8 | 1353 |

| 6 | 0.47 | 10,2 | 2,5 | 2106 |

Table 3 presents the parameters of the pipes of steel light welded water and gas pipes.

Table 3

| Conditional pass, Du, mm. | Weight per meter, kg. | Outer Diameter, Days, mm | Wall / board thickness, S, mm. | The number of meters in one ton, Nt, m |

| 150 | 15,88 | 165 | 4,0 | 62,96 |

| 125 | 13,42 | 140 | 4,0 | 74,54 |

| 100 | 10,85 | 114 | 4,0 | 92,16 |

| 90 | 8,44 | 101.30 | 3,5 | 118,5 |

| 80 | 7,34 | 88,50 | 3,5 | 136,3 |

| 65 | 5,71 | 75,50 | 3,2 | 175,3 |

| 50 | 4,22 | 60 | 3,0 | 237,1 |

| 40 | 3,33 | 48 | 3,0 | 300,4 |

| 32 | 2,73 | 42,3 | 2,8 | 366,6 |

| 25 | 2,12 | 33,5 | 2,8 | 471,7 |

| 20 | 1,5 | 26,80 | 2,5 | 667,5 |

| 20 | 1,42 | 26,80 | 2,35 | 705,7 |

| 15 | 1,16 | 21,30 | 2,5 | 862,7 |

| 15 | 1,1 | 21,30 | 2,35 | 910,5 |

| 10 | 0,74 | 17 | 2,0 | 1352 |

| 8 | 0,57 | 13,50 | 2,0 | 1763 |

| 6 | 0,37 | 10,20 | 1,8 | 2682 |

Metallurgical plants produce such products on order. Therefore, the dimensions - wall thickness, diameter and length may differ from the data given in the tables.

The length of the pipes is regulated by GOST, but non-standard products may be produced in agreement with the customer

Metallurgical plants produce such products on order. Therefore, the dimensions - wall thickness, diameter and length may differ from the data given in the tables.

It should be noted that the weight of galvanized pipes for water supply is 3% more than the value of this parameter of un galvanized ferrous metal products. But according to GOST 3262 75, the maximum mass deviations should not exceed 8 percent (for a batch this figure is: 10%).

Technical requirements

The GOST for water and gas pipes says that these products are divided into steel black and galvanized. According to the installation method, they are threaded and welded. Consider the requirements for them in more detail.

The pipes are black.

- The presence on the surface of the film, blisters, sunsets is excluded.

- Minor defects are allowed: rowaniness, risks, dents, scale layers, cleaning marks.

- Checking the exposure of hydraulic pressure in accordance with GOST for steel water and gas pipes is carried out according to the following indicators: for ordinary and light products - 25 kgf / m² (2.4 MPa); for reinforced - 32 kgf / m² (3.1 MPa); for pipes on special order - 50 kgf / m² (4.9 MPa).

- Examination for the distribution of steel water and gas pipes GOST 3262 75 is carried out taking into account the following figures: with a nominal diameter of 15 ≤ Du ≤ 50 mm - from 7%; if Du ≥ 65 mm - not less than 4%.

Important! But provided that the metric characteristics of the final product do not go beyond the permissible deviations.

Galvanized pipes. Requirements for steel water and gas galvanized pipes GOST 3262 75 are formulated as follows:

- the thickness of the zinc coating should be at least 30 microns;

- on a galvanized surface, the presence of bubbles, peeling from the starting material, as well as various inclusions (hartzink, charge, oxides) is not allowed;

- galvanized water pipes should be continuous;

- rare traces of capture and flux spots may be present on the surface;

- GOST 9307 allows re-coating of defective areas. But only if they occupy no more than 0.5 percent of the surface of the galvanized water pipe.

The assembly of the pipeline from products of this type is carried out mainly by a threaded connection. It is not recommended to use welding without special electrodes, since the protective anticorrosive layer of zinc will simply burn out. If you still decide to mount galvanized pipes in this way, it will be useful to listen to the opinion of professionals. They advise using electrodes with calcium fluoride or rutile coating with a diameter of 3 mm.

To increase the service life of galvanized water pipes, they are subjected to heat treatment.

Steel threaded pipes. These products are available with short and long threads. The requirements for it are presented in table No. 4.

Table 4

| Conditional pass Do millimeters |

Type of thread and its length to the run, millimeters | amount thread |

||||

| short | long | |||||

| 150 | 36 | 42 | 11 | |||

| 125 | 33 | 38 | 11 | |||

| 100 | 30 | 36 | 11 | |||

| 90 | 26 | 33 | 11 | |||

| 80 | 22 | 30 | 11 | |||

| 65 | 19,50 | 27 | 11 | |||

| 50 | 17 | 24 | 11 | |||

| 40 | 15 | 22 | 11 | |||

| 32 | 13 | 20 | 11 | |||

| 25 | 11 | 18,0 | 11 | |||

| 20 | 10,50 | 16 | 14 | |||

| 15 | 9 | 14 | 14 | |||

| 10 | — | — | — | |||

| 8 | — | — | — | |||

| 6 | — | — | — | |||

Welded water and gas pipes. The requirements for products of this type fully coincide with the requirements for products made of black steel. Nevertheless, one cannot ignore the two nuances contained in GOST.

- If the production of water and gas pipes with a passage of 1.5 cm and above is carried out by kiln welding or by the reduction method, a shallow form of small height (up to 0.5 mm) is allowed at the location of the weld.

- On the threads of the thread at the seam may be black. But under one condition: the normal profile height should not be reduced by more than 15%. However, GOST 3262 75 allows the consumer to demand a decrease in this parameter by no more than 10%.

As you can see, the nomenclature of water and gas pipes is very extensive. The increased demand for these products is due to their high strength and long service life.