Corrosion-proof fittings are among the most important components of the pipeline. They are used to connect pipes, create branches, turns, transitions to a diameter of a different size and so on. These parts are widely used in chemical, food, pharmaceutical industries. As practice shows, without the use of stainless steel fittings, it is impossible to create metal structures that work in conditions of negative environmental impact.

Fittings for communications for various purposes can be made of stainless steel, they are resistant to corrosion

Content

Features

The functions performed by stainless fittings are exactly the same as any other standard counterparts.

By and large, metal connectors are the standard in plumbing. They began to take their positions under the pressure of the popularity of cheaper (but less practical) polymer parts only now. Previously, pipelines were equipped exclusively with steel fittings. After all, any such engineering communications must be reliable. However, steel is not showing its best. This metal is subject to corrosion. Even under normal conditions, rust will sooner or later appear on steel, let alone use it in heating and water supply systems. This is why stainless steel fittings are the preferred option for pipes.

Unlike ordinary, stainless steel copes well with its functions as a raw material for the manufacture of pipes for industrial as well as civil purposes. It is inherent sufficient resistance to moisture and microorganisms to be suitable for operation for at least several decades.

However, sooner or later, steel will also begin to collapse from corrosion. This process for the metal elements of the pipeline, unfortunately, is irreversible, it can only be delayed. However, this did not greatly affect the position of stainless pipes and fittings. As before, they are widely used in plumbing equipment, mainly industrial, heating pipelines, utilities, which transport a working environment other than heated water, etc. In other words, where the natural qualities of polymer pipes are already lacking.

Advantages and disadvantages

The advantages of stainless fittings include:

- increased resistance to corrosion;

- strength;

- durability;

- inertness to the effects of chemicals;

- wide range of operating temperatures;

- market availability;

- ease of installation.

On a note! Of course, for fittings made of polymeric materials, the value of this indicator is higher, but when compared with ordinary black steel or even galvanized steel, this is a big step forward.

Of the minuses, experts and home masters distinguish:

- high cost;

- sooner or later, the part made of steel will collapse.

The high cost of stainless steel is the main negative point. Accordingly, fittings made from it will cost more than connecting elements made of black steel. On the other hand, this factor is leveled by the excellent qualities of stainless steel parts. Black steel will begin to rust after some 10 years of active use, and this period is not critical for stainless steel.

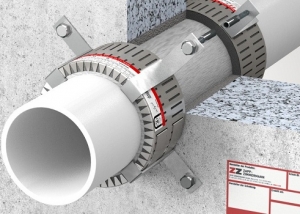

Installation of stainless fittings is a simple and convenient process that does not require special skills

As for the destruction, it must be understood that no matter how metallurgists improve steel, this phenomenon can be avoided. Especially where the assembly was performed poorly. Then the fittings will need to be replaced after 20-30 years.

Types and differences

Modern industry produces stainless steel fittings in various designs and various functional orientations. There are really a lot of similar products. So, there are fittings used to connect pipes of a particular type, for example, corrugated. In addition, these products differ depending on the design tasks being solved with their help. The simplest criterion for dividing fittings into types is the connection method. From this point of view, stainless steel fittings are:

- threaded;

- compression;

- welded;

- crimp.

Stainless steel threaded fittings are used most widely. There are a great many variations of such products. Starting from traditional designs focused on working exclusively with end threads, and ending with today's fashionable “Americans,” the design of which includes two additional union nuts.

In any case, threaded products operate according to one principle. There is a pipe on which an external or internal thread is cut, and there is a fitting with a threaded counter thread. Both parts are connected together by twisting, and then tightened in one way or another. In more complex models, this is done with the help of additional nuts, and in simpler models, the body of the fitting or pipe is twisted.

Compression fittings are essentially the evolution of threaded products. They are equipped with conical ends and their design includes crimp union nuts and gaskets.

On a note! The use of gaskets allowed to solve the main problem of products of this type - gradual depressurization.

Welded fittings are welded to the pipes. These products have been used since ancient times. In the world of plumbing, along with threaded, they became pioneers. It turns out that the welded joints are really tight and reliable, to their quality, subject to the work of an experienced welder, claims, as a rule, do not arise. That's just without the use of special equipment, it is impossible to perform welding. Actually, it will also fail to disassemble the pipeline branch after welding.

The design of crimp fittings consists of a body and side nuts or washers, which are deformed by a special tool. Usually used to connect pipes from polymers, most often metal-plastic pipe products.

Varieties

Both stainless steel pipes and fittings are designed to solve certain problems in water supply or heating systems. According to this criterion, the connecting parts are divided into the following types:

- couplings. Such devices are designed to connect straight pipe segments of the same type and made of identical material;

- adapters. Details of this kind are used to implement the transition between the pipe segments of different types;

- bends. Provide rotation of the axis of the pipeline at an angle of 45-90 degrees. Steeply curved, bent, single and double bell-shaped bends are produced;

- corners. Change the direction of movement of the working medium down, up or sideways by a fixed 45.90 and 180 degrees;

- crosses, tees. They are installed where the trunk forks into 3 and 2 threads, respectively;

- stubs.These parts are placed at the dead ends of the pipes during repair work in order to temporarily block the flow of the working medium;

- flanges. They are used to connect various devices with bolts, studs or to insert plumbing fixtures;

- fittings. Transition to a flexible hose from a pipe. Most often used to connect household appliances;

- shutoff valves. It is used to stop or start the flow of the working medium in the pipeline.

The range of stainless steel fittings includes connecting and transition elements, shut-off and control valves and other types of parts

Leading manufacturers

The abundance of offers in the segment of stainless fittings of the domestic plumbing market cannot but please home craftsmen. But, on the other hand, in order not to waste money, it is necessary to purchase such products from time-tested manufacturers. The following companies are among the world brands whose quality of manufactured fittings you have no complaints about:

GENEBRE (Spain). The history of the brand began with the opening in Barcelona in 1981 of a small workshop for the production of fittings for pipelines. Over time, the workshop was transformed into a small factory, and then into a huge company, which gained fame on all continents. For more than 36 years, the company has specialized in the production of butterfly valves, strainers, stainless steel crimp fittings and other valves.

AWH (Germany). This company was founded in 1900, and for the second century its products have been very popular.

Helpful information! Today the assortment of the company includes more than 38,000 (!) Standard positions. In addition, AWH manufactures products according to customer drawings.

The company produces the following types of parts from stainless steel: milk coupling, ball valve, disk lock, thread-cutting products, welding fittings and other valves;

EUROBINOX (France). This brand began its activities in 1982. And to this day, its products continue to be successfully exported around the world. Today EUROBINOX company offers such stainless steel products:

- ball threaded valve;

- air operated butterfly valve. If this option is unnecessary, you can buy a disk shutter without a pneumatic actuator;

- check valve;

- welded fitting (matte and polished).

NIOB FLUID (Czech Republic). This company uses different grades of stainless steel for the production of fittings used in the food, pharmaceutical and chemical industries. The issue was launched in 1992, and to date, the NIOB FLUID brand has become widely known thanks to the production of:

- direct and three-way shut-off valves with electric, pneumatic or manual control;

- half-turn and ball valves;

- food fittings;

- check valves and other stainless steel products.

How to extend the service life

When purchasing stainless steel fittings even from world-famous brands, remember that such products require adequate handling. In order not to encounter problems when operating these devices, be guided by the following rules:

- when purchasing a large batch of connecting parts, carefully read the conditions of loading, transportation and unloading. Inaccuracies can cause mechanical defects. The packaging of the fittings must be waterproof. And these devices should be transported in well-fixed wooden boxes protected from penetration of dirt, moisture and dust;

- Store purchased connectors in a dry and clean environment.

- wipe fittings with warm water. Do not use chlorine-based detergents that are popular today with disinfectants.

By fulfilling these simple requirements, you will extend the life of stainless steel fittings.