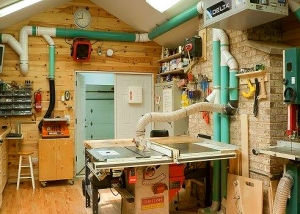

Today, there are many manufacturers of polymer pipe products in the air conditioning industry. The key factors behind its popularity are the convenience and speed of duct installation, as well as a presentable appearance. Therefore, a flexible plastic ventilation pipe is the main element in the creation of exhaust and fresh air intake systems in apartments, country houses, supermarkets, etc.

Domestic use

More recently, installation of air conditioning systems in residential premises was carried out using mainly galvanized pipes. But such properties as unreliable joints, difficulties in maintenance and prophylaxis, a tendency to corrosion damage and aging led to the fact that they began to be replaced by plastic (round or rectangular) pipe products. Today on the market you can find flexible ducts for ventilation from polymers such as polyurethane, polyvinyl chloride, polypropylene.

Good to know! Pipes used in the installation of air conditioning systems belong to the category of medium type.

Polyvinyl chloride is an environmentally friendly material. Pipes from it are easy to mount, they are airtight and cheap, so the purchase of PVC products does not greatly burden the family budget. Another important point: a lightweight flexible plastic duct is much easier to hide under a suspended ceiling. Therefore, the demand for such products is constantly growing.

Advantages and disadvantages

Experts highlight the following positive qualities of flexible plastic pipes for ventilation:

- the ability to install systems of complex configuration without the use of additional elements. The design of the flexible duct provides the ability to easily change the direction of the ventilation line and easily rotate at the desired angle;

- due to its light weight, the cost of fasteners is reduced. In addition, lifting such pipes to a height is not fraught with difficulties. Therefore, only 1-2 workers can perform installation of a ventilation system from plastic flexible ducts;

- the materials in question are characterized by a significant working resource, resistance to aggressive environments and corrosion. They also differ in durability;

- unification of the diameters of flexible ventilation pipes makes it possible to carry out installation together with elements whose design has increased rigidity;

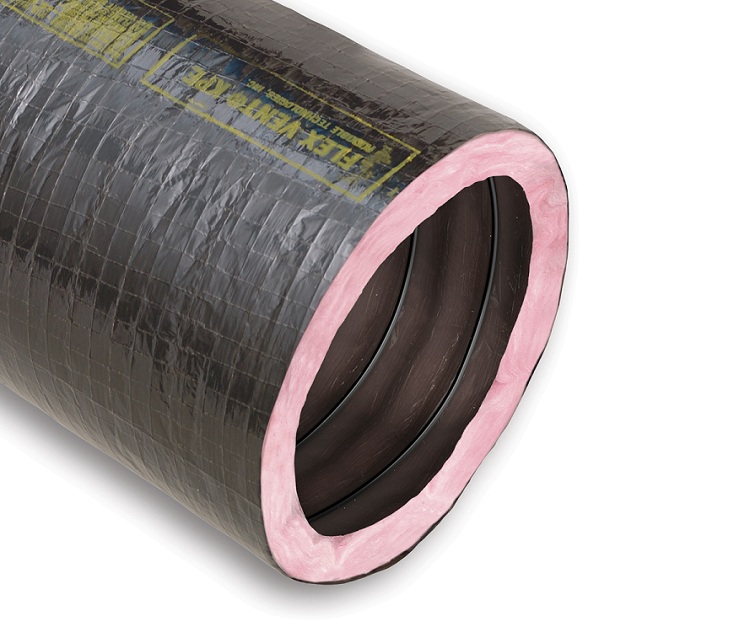

- the surface of the plastic duct is easily insulated with a variety of heat-insulating materials. In addition, modern industry produces a fairly large assortment of products with applied thermal protection. The insulated flexible ventilation pipe can be mounted outside buildings, as well as in unheated rooms.

The disadvantages of such products include:

- if the installation requirements are not complied with, during ventilation, the noise level may increase significantly;

- the design of the flexible pipe is a multilayer combined structure with a small layer thickness. This, on the one hand, allows you to reconfigure the duct without any difficulties. But on the other hand, with inaccurate installation, its surface can easily be damaged. Therefore, when attaching flexible pipes, as well as during commissioning, it is necessary to carefully monitor the integrity of the network.

In principle, such disadvantages cannot be called critical, however, when installing these qualities should be remembered.

Types of household ducts

The following types of flexible ventilation pipes are on sale:

- multilayer structures based on polyester compounds and aluminum foil. The necessary level of rigidity is provided by the presence of a wire frame.

Good to know! Flexible aluminum ducts meet fire safety requirements, and when exposed to open fire do not emit volatile substances harmful to human health.

- flexible pipes with double-sided polyvinyl chloride coating. Such advantages are inherent in them:

- minimal airflow resistance. Due to this property, the level of noise arising during the operation of the ventilation system is reduced;

- plastic ducts less accumulate static electricity. However, you still have to ground the entire system.

This type of soft ventilation pipe has one significant drawback. It consists in the possible peeling of the coating with excessive stresses on twisting and stretching / compression.

- frameless corrugated aluminum pipes, the raw material for the manufacture of which used a single sheet of metal. This technical solution provides them with increased rigidity and strength. Therefore, these products are resistant to mechanical damage and have a significant working resource. They can be used to ventilate rooms with air containing a large amount of large mechanical impurities.

Industrial use

Flexible air conditioning and ventilation ducts are used in educational institutions, hospitals, large public centers, etc. We all know this. But there are still branches of modern industry in which such products simply cannot be dispensed with. It is about building tunnels, mines and mine workings. Conventional means for supplying air are not applicable here, so specialized ones are used, including flexible shaft ventilation pipes. Due to the large diameter, the output of polluted and the influx of fresh air masses they provide in sufficient volume.

Features Flexible mine shaft ventilation pipes are of two types:

- stitching pipe. For stitching parts, specialized sewing machines are used. At the final stage of the joining procedure, the seam is carefully poured with the appropriate adhesive;

- welded pipe. Welding is carried out by heating the ends of plastic parts, as a result of which they soften, and after joining each other under a certain effort form a single whole. This eliminates even minimal air leakage and thus provides the necessary tightness.

Flexible mine shaft ventilation pipes are manufactured in accordance with the requirements of the following regulatory documents: TU 3146-017-25779585-06 and TU 3146-002-25779585-08.

Helpful information! As a raw material for the production of such products, non-combustible reinforced antistatic vinyl artificial leather is used, which is a fabric base of chemical threads. On both its surfaces - internal and external - a layer of special PVC coating is applied.

For industrial purposes, pipes made of artificial non-combustible fabric coated with a protective layer are used.

Categories. These products are usually divided into three types:

- products manufactured for mines of the mining industry or coal mines, including those where the dust and gas content is at a dangerous level. Such systems must withstand pressure not lower than 1000 kPa;

- pipes for mines and mines with similar conditions that can withstand pressure up to 500 mPa;

- air ducts for mines and coal mines in the airspace of which there is no dust and gas. Despite such facilitated conditions, one serious condition is put forward for such products. It is formulated as follows: a flexible ventilation shaft pipe must remain operational at a pressure of the same 500 MPa.

All the above types of ducts are attached by suspension to a tensioned cable or wire. Here it is necessary to prevent sagging of the pipeline. Otherwise, the volume of air entering the mines and mines will decrease.

Exploitation. In this regard, it is necessary to observe a number of important conditions:

- to subject pipes to blows with a blunt, and even more so sharp object is not allowed;

- Do not transport ventilation plastic products. This may cause damage to the material;

- in the event of a fire, it is necessary to immediately begin to extinguish the flame that engulfed the ventilation pipes. You can use all available methods and means - water, fabric, foam, inert gases and so on.

- inspection of the air duct should be carried out along the entire length at least once a day;

Regardless of the type of ventilation pipes you need to make sure that you have a certificate of compliance with the requirements of regulatory documents in force in our country.