In order to stay in a private house as comfortable as possible, it is important to properly arrange and establish all communications. And home plumbing is no exception. "What pipe is used for running water underground?" - This question is asked by everyone who is just starting to housekeeping and has no experience in laying communications.

Content

Basic requirements for pipes for water pipes in the ground

Digging wells and drilling wells are quite expensive activities, so residents of private houses increasingly prefer the installation of an underground water supply. The optimal type of pipe should be selected depending on many factors: the purpose of the water supply, the length of the site, and the budget. There are several general requirements that all must meet. underground water pipes:

- Quality. Pipes must be produced in accordance with technological standards, their surface must be flat, smooth, without any dents, creases or bulges.

- Reliability. Implied resistance to mechanical stress, the ability to withstand high pressure.

- Durability. The material from which the pipe is made must be wear-resistant, not exposed to biological factors: corrosion, rust, rodents.

- Resistance to sharp changes in temperature. Resistance to soil freezing is also taken into account. Even a well-insulated pipe will experience constant thermal changes, which should not affect its performance.

Also, pipes for water pipes in the ground, especially designed for supplying drinking water, must be made of environmentally friendly material. Then the water passing through them will remain transparent, no odors and impurities will be detected in it.

Varieties of water pipes

The right choice of pipes is the first condition for the effective operation of the entire water supply system. In today's market you can find quite a lot types of pipes, and each of them has its own advantages and disadvantages. In order to determine exactly which pipes are best for underground water supply, it is necessary to consider in detail the characteristics of each variety.

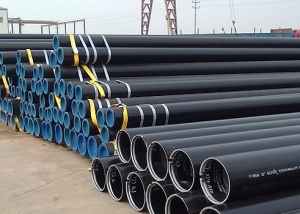

Metal pipes (steel, cast iron, copper). Pipes made of metal gradually cease to be used, as they have a lot of disadvantages. Steel structures are very heavy, quickly corrode, and their installation is difficult to do with your own hands. Of all types of metal pipes, copper pipes can be considered an exception.

Important! The service life of copper pipes is many times greater than the operational qualities of steel pipes, but at the same time, their purchase and installation (especially underground) will be quite expensive.

Plastic pipes. Products having a multilayer structure. Water pipes are made of polymer, additionally reinforced with aluminum. Strong and wear-resistant, devoid of thermal expansion.This option is better than steel, but cannot be considered the most practical, since the cost of metal-plastic pipes is high, especially with respect to plastic.

Plastic pipes. A relatively new type of pipe, which has become an excellent alternative to metal structures. Unlike steel, plastic does not rust; holes and leaks do not form in it over time. Plastic pipes have a low cost, they are easy to install, their installation can be carried out even without special equipment. For water pipes made of plastic, it is easier to find fittings and accessories. There are several types of plastic pipes, and each of them is suitable for different types of work.

Pipes PND (polyethylene of low pressure). A good choice for outdoor work, but when buying, you should pay attention to the marking of the pipe. PND pipes of the PN10 brand are better suited for underground water supply. PND pipes of the PN6 brand are available for sale, their cost is lower, but the properties do not meet the specified requirements. This type of pipe does not violate the quality of drinking water. Despite the high density (HDPE pipes withstand up to 10 atmospheres), they are extremely flexible. The desired shape of the pipe can be given without much effort, for better work it is better to find a pipe bender. HDPE pipes are usually available in black, possibly with blue marking stripes. At the same time, polyethylene pipes do not tolerate cold well and need high-quality thermal insulation, including when laying underground. Their installation is undesirable at temperatures below 5 degrees.

There are also LDPE pipes made of high pressure polyethylene, but due to the low density in the economy they are practically not used.

PVC pipes (polyvinyl chloride) can be used for outdoor work, but only as a pipeline for cold water supply. PVC pipes do not tolerate high temperatures, and the passage of water above 40 degrees significantly reduces the service life.

Helpful advice! In retail chains you can find PVC pipes in gray and orange. Orange PVC pipes are used for laying sewers, including underground. The density of the walls of gray PVC pipes is less high, but they are quite suitable for laying under small layers of soil.

Polypropylene pipes. They have very high strength and resistance to temperature changes. Polypropylene has a high melting point, so it can be safely used for hot water supply and even heating systems. It is worth paying attention to the fact that pipes from this material are completely devoid of flexibility. You can find a solution to this problem: turns and bends of the system should be carried out using polypropylene corners and tees. Polypropylene structures are able to withstand the highest pressure, for example, when laying underground to a depth of more than 2 meters. This is especially true for northern regions with a high degree of soil freezing.

Features of the choice of water pipes for laying in the ground

Which kind of pipe to choose for future water supply also depends on the selected water source and the type of soil prevailing on the site.

When the main as a direct source of water, the type of pipe is not fundamental. As in any other case, the main water supply system is laid to a depth of 0.5 m below the zero freezing point of the soil. Typically, the distance from the surface of the earth to this limit is 1.2-1.5 m. When laying a water pipe from a well, you must either purchase pipes that are highly resistant to cold, or properly insulate the pipeline. Steel water pipes are less sensitive to low temperatures, but, taking into account the rest of their shortcomings, it is better to pay attention to polypropylene structures taking into account thermal insulation.

In order for the water supply to fulfill its functions in the cold season, the pipes need to be insulated

If the water supply is planned as a means of supplying water for irrigation, then it is not necessary for him to purchase pipes from too dense material. This type of plumbing system is allowed to be deepened a small distance from the soil surface.

Depending on the type of soil, the selection of pipes may have the following features:

- sandy, loose and clay soil. The not very rough structure of such soil makes it possible to lay pipes of light materials: metal-plastic and flexible varieties of plastic (HDPE, PVC). In this case, the soil will not exert pressure on the pipeline and will not create obstacles when digging a trench under the water supply. If it is necessary to install a water pipe with a wide diameter in clay soil, it is better to use corrugated pipes;

- stony, hard soil. The pipeline in areas with problematic soil should be dense enough to withstand high loads. It is better to use the trenchless installation method of the water supply system using the puncture method (a plastic tube of smaller diameter is placed in the cavity of the steel pipe). Exceptionally plastic pipes, especially those with a trench installation method, will not work, as they will not be able to withstand pressure for a long time.

Common mistakes in laying water pipes in the ground

Instability in the operation of the water supply system can be associated not only with the wrong choice of pipe variety. Installation and installation errors also do not have the best effect on system performance. One of the common mistakes, often caused by the desire to save on laying water pipes, is the lack of thermal insulation. The freezing of water in the pipes threatens not only the loss of water supply or sanitation, but also damage to the structure of the pipes. If in the winter months the water froze in the system naturally, then it can only thaw out by the end of April-May. Finding a site with frozen water and eliminating clogging will also be difficult.

Helpful advice! Warming of the water supply system by laying a heating cable can hardly be called the most budgetary (due to the mandatory purchase of a transformer and energy consumption), but its effectiveness is a proven fact. A heating cable will prevent freezing of water even at the lowest ambient temperatures.

For additional protection of both pipes and heating cables, insulating materials can be used. Energoflex insulation (13 mm thick will be enough), polystyrene or fiberglass will do.

A lot of problems can bring inconsistency with the site plan at the beginning of repair work on the installation of the pipeline. Be sure to consider the possible location of existing communications, so as not to hurt or damage important lines when laying.

There can be several ways to find underground water pipes or any other pipes. Firstly, you should contact the utility for information on the passage of underground routes near the site. Most likely, it will be possible to find the relevant documentation in Vodokanal or in the housing and communal services department. Secondly, you can use technical equipment to find passing pipes. Metal pipes are detected using a metal detector. Hot water pipes can be found underground using a thermometer or thermal imager, even at a depth of several meters. The laying of new communications underground must be carried out according to certain rules, at a distance indicated by building codes.