Water supply is something without which it is impossible to imagine a modern private house or land. In order to use the water supply as comfortable as possible, it is not necessary to resort to the help of professionals. Laying a water pipe in the ground is not a technologically complicated process, but it requires accuracy and attention to detail.

Content

- 1 The choice of water pipes for laying in the ground

- 2 Tools for installing water supply

- 3 Pipeline conditions

- 4 Methods for laying an external water supply

- 5 How to lay a water pipe underground?

- 6 Installation of water pipes when laying in the ground

- 7 Problems encountered when installing pipes in the ground

- 8 Water pipe insulation

The choice of water pipes for laying in the ground

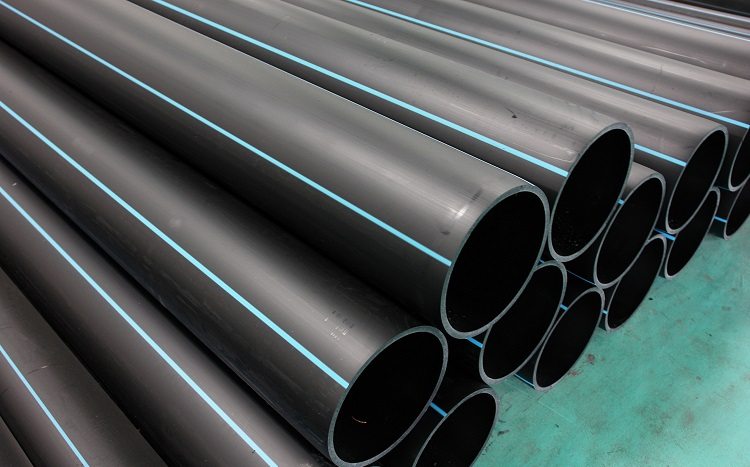

Type of pipes for underground water supply, their diameter and material of manufacture will be determined depending on the functional purpose of the pipeline. Due to the significant disadvantages of steel pipes, previously widely used in the economy, it is worth giving preference plastic pipes. Plastic also has many varieties, but for private purposes, low pressure polyethylene (HDPE) and polypropylene are best suited. Plastic pipes have a long service life compared to metal pipes; fittings and accessories can be easily selected for them. There is also a higher throughput of plastic pipes.

Polyethylene pipes. This option is well suited for laying water pipes in the ground, since polyethylene has high strength, resistance to temperature extremes, affordable price. It is almost impossible to damage HDPE pipes in the ground. Can manually install polyethylene pipeswithout using special tools or instrumentation (using fittings). HDPE pipes do not affect the quality of water, therefore, they are used for laying domestic water pipes. If it is necessary that the polyethylene pipe withstands constant pressure, it is worth purchasing a model marked PN10. Such pipes are able to withstand pressure up to 10 atmospheres. For underground water supply it is undesirable to use PND PND pipes - such pipes have a low density and, accordingly, a shorter service life.

A disadvantage of polyethylene is the relatively high thermal expansion of the material. During installation, this is usually taken into account, therefore, L- or P-shaped bends are introduced into the system.

Polypropylene pipes. Like polyethylene, polypropylene is very durable and is not exposed to biological and chemical factors. Its only drawback is the lack of flexibility, but this problem is solved by means of adapters and corners. A pipe bender is not required to lay a water pipe from polypropylene pipes in the ground. Polypropylene pipes can also be connected to systems of other materials, for example, with steel water supply.

"Helpful advice!" For plumbing designed for the supply of hot water, it is better to choose polypropylene pipes marked PN20 or PN25. These pipe models contain a reinforcing layer of fiberglass or aluminum foil.When hot water passes through them, the pipe will not soften or deform.

The diameter of the water pipes for laying in the ground depends on the length of the pipeline. The calculation is made at an average rate of water in the pipe up to 2 m / s. Pipes with a diameter of 20 mm are suitable for systems whose length does not exceed 10-15 meters. Pipelines up to 30 meters long can be laid using pipes with a diameter of 25 mm. For large-scale systems over 30 meters, it is worth purchasing pipes with a diameter of 32 mm.

For a quality connection of pipes with fittings, you need to choose products from the same manufacturer

Before starting laying work, you must ensure the quality of the purchased pipes and accessories. The surface of the pipes should be smooth, without any roughness, roughness or sagging material. It is desirable that the fittings and pipes were produced by the same company.

Tools for installing water supply

In order to qualitatively carry out installation work on laying water pipes in the ground, it is far from always necessary to resort to the help of special equipment. Many of the fixtures for laying are available on the farm in most homes. You will need the following set of tools:

- pipe cutter, sharp scissors for cutting pipes, knife or hacksaw;

- drill or perforator;

- sandpaper;

- construction pencil;

- roulette;

- set of gas and wrenches (for tight tightening of fittings);

- soldering iron (if the installation will be carried out by hot welding);

- earthwork tools: shovel, compact scrap.

Pipeline conditions

The laying of any type of water supply is possible only subject to certain conditions established by regulatory documents. Compliance with technical standards ensures stable and safe operation of the entire system.

Calculation of the depth at which water pipes can be laid in the ground: the depth indicator of the water system will be determined by the depth of freezing of the soil. These data are individual for each region and climatic zone. You can get the most accurate information about the depth of freezing in the local meteorological service. This value also depends on the composition of the soil, the density of the vegetation cover, the presence of groundwater, and the degree of heating by the sun. This indicator is very important, since freezing of water in the pipes threatens the occurrence of pipe depressurization, cracks and ruptures. The sunlight penetrating through the soil also has a negative effect on the integrity of the pipes.

For the northern regions, the laying depth is at least 3-3.5 m. For areas located in the middle lane, an indicator of 2.3-2.5 m is taken. For the southern regions, 1.5 meters will be sufficient. It is desirable to lay the water system half a meter deeper than the calculated freezing depth of the soil.

The presence of third-party communications in the land is of great importance. Water pipes are allowed to be laid from sewer communications at a distance of at least 2-2.5 meters. If electric or telephone cables pass on the site, the pipeline should be separated from them by 0.75-1 meter. In those cases when the intersection of the water supply system with any other pipeline is inevitable, the distance between the communications should be from 0.2 meters. Moreover, water pipes are laid above an existing pipeline.

The pipeline can pass near the bottom of the foundation of the house on the site. In this case, the probability of building settlement should be considered. For this purpose, the water supply system is laid at least half a meter above the foundation. And above the pipe, a soil gap of 15-30 cm is formed.In places of intersection with the foundation, you can lay a protective strip of tarred rope and softened clay. It is also advisable to clarify in the communal service whether the main and engineering networks and routes pass on or near the site.

Methods for laying an external water supply

It is possible to lay water supply outside the house both on the ground and in the ground. The trenchless method is used when laying an external water pipe from polypropylene pipes, but at the moment it is considered more promising than demanded.

There are several methods for trenchless laying:

- reorganization. Implied replacement of old water systems to new pipes. If the site already had an external water supply that does not cause any special problems, then there is no point in changing it by laying pipes in a trench. New pipes are mounted both by the relining method (i.e., hauling the new pipe in the thickness of the old one) and by the renovation method (the old pipe is not dismantled in advance, but is destroyed simultaneously with the laying of the new structure);

- piercing. This method can be considered when laying pipes whose diameter does not exceed 150 mm. Also, its use is possible only in small areas. To lay pipes in this way, it is necessary to dig two pits, passing, for example, on both sides of the track. Using a hydraulic jack, a steel pipe is pushed into the pit, after which a polypropylene pipe or HDPE pipe is introduced into its cavity.

Trenchless methods are used in rare cases, referring to their inconvenience and high cost. They can be relevant when decorative or functional elements are present on the site that cannot be subject to demolition.

How to lay a water pipe underground?

The most effective, convenient, but at the same time long-term way of carrying out a pipeline on a site is laying pipes in the ground. The water supply hidden in the ground is almost impossible to damage, and it will not spoil the aesthetic appearance of the site. To perform work by this method, it is enough to dig a trench in the right direction under the water supply.

Before starting work, the territory of the site is marked according to the plan-scheme. In this case, it is very convenient to use a cord for marking. They dig a trench in any convenient way, even with the help of an ordinary manual shovel. If the soil on the site is rocky and solid, it is best to consider the possibility of using construction equipment. This option is more expensive, but also more productive.

"Helpful advice!" Digging not only trenches, but also drain pits, foundations, it is much more convenient to carry out a bayonet shovel with rounded edges. With the help of such a tool it is possible to work productively even with soils of increased hardness. To clean the cut soil and the bottom of the trench, a shovel is useful.

If the depth of the trench is not determined by individual factors, then its width is usually standard - 70-90 cm. It can be wider or already declared parameters depending on the number of pipes. The dug trench before laying pipes into it must be prepared, namely, to level its walls and carefully seal the bottom.

Before strengthening, make sure that no large pieces of soil, stones, or construction debris remain at the bottom. The next step will be to create a cushioning pad for the bottom of the trench. It is evenly filled with river sand, the layer of which can reach 10-12 cm, after which this layer is abundantly spilled with water and compacted with force.

Backfilling of the trench is carried out using soil excavated during trench digging. It is desirable that the land intended for backfill is clean and loose.Stones larger than 20-30 mm are removed from the soil. Spraying should be done slowly and accurately, the soil can not be strewed on the laid water supply. First, the earth is rammed in small layers of 10-20 cm on each side of the pipe, thereby fixing it in a horizontal position. Fine gravel or crushed stone can be used to compact dusting. The sealing layer is laid at a distance of 5 cm from the protruding edge of the pipe, then is again filled with earth.

The layout of the pipeline should be carefully thought out. It is necessary to take into account such moments as the location of communications already existing on the site, the distance between buildings and other objects. The plan should show all the bends and bends of the pipeline. Moreover, the presence of too sharp angles when cornering the system is not allowed, as this often becomes the cause of clogging of the entire sewer. The drains in these sections of the water supply system need much more force to move, which is why deposits begin to form on the inner surface of the pipes.

Installation of water pipes when laying in the ground

Laying water supply pipelines from pressure polyethylene pipes can be carried out by welding or using crimp (compressor) fittings.

Installation of external communications from pipes is most often carried out by the welding method. After the correct welding cycle, a one-piece integral product is obtained. Non-separable joints are suitable for the trench method of laying pipes, since in this case any further structural amendments are excluded.

Welding and installation work with polyethylene pipes can be carried out according to the basic scheme, or by the route method. The last option is to pre-weld individual pipes, after which the resulting sections are transferred to the working object already in finished form. The section length can be any size convenient for transportation. Sections are welded into a single system already in place, after which they are neatly, without violating the bending radius, placed in a trench.

At laying water pipes from polypropylene pipes You can also use the method welding. For polypropylene, the optimum temperature for heating the soldering iron will be 260-270 degrees. It is necessary to pay attention to the heating time. For polypropylene pipes with a diameter of 25 mm, 9-10 seconds of heating will be sufficient, for pipes with a diameter of 32 mm this time should be increased by 2-3 seconds. Due to the heating, the parts of the polypropylene construction can become very bent, therefore, for a quality connection, it is important not to damage the surfaces of the products. Especially critical consequences can be after turning the parts along the horizontal axis during welding.

"Helpful advice!" In no case should blackening of the plastic be allowed during welding. The blackened melted area must be removed, since such a pipe is damaged and is not subject to further operation.

A serious mistake in soldering polypropylene pipes there will be too little heat, in which case the connection will be fragile. In no case should there be traces of water, dirt, dust on the elements connected by the welding method. To prevent gaps between the edge of the pipe and the stops of the fitting, which also often cause leaks and breakdowns in the pipe, the depth of the pipe is initially marked at the end of the pipe. It is not worth removing the swarms that inevitably appear during welding immediately after soldering - this leads to pipe deformation.

In order not to make a mistake with the depth of fitting fitting on the pipe, you need to pre-mark the parts to be welded

After laying the water pipes in the trench, it is necessary for several days to test the piping system under different pressure.Only after the pipes can be tested for sufficient strength can the system be commissioned.

Problems encountered when installing pipes in the ground

The trench method of laying water pipes is undoubtedly optimal for most sites. But it is also worth mentioning the difficulties that may arise during the installation of polypropylene pipes and HDPE pipes in the ground, as well as how to solve them.

The structure of the soil limits the possibility of digging to the required depth. If the soil is too hard, and this creates inconvenience when digging a trench, it is recommended to wait for a wetter season to start work. Moist soil is much easier to handle with hand tools.

Too loose, constantly crumbling soil can cause serious problems when operating a pipeline buried in a trench. Therefore, with this type of soil, it is better to mount the water pipe by the puncture method. First, a steel pipe is laid, then a plastic pipe is placed in its cavity. Loose soil can also be strengthened with special geotextiles.

An object is located on the site (for example, a structure), which interferes with the straight pipe laying. In this case, a more rational solution would be to carry out water supply by a trenchless method of laying. The piping can also be further insulated with a steel casing.

Water pipe insulation

A correctly selected type of pipe and its laying depth allow avoiding freezing of water in the pipeline in the cold season. But most outdoor pipelines still need additional protection. It is quite problematic to find and get laid water pipes in the ground, so it is better to provide quality insulation to the pipes in advance. To insulate a pipe held underground, you can use one of the available methods.

Piping in a case. The main, existing water supply is laid inside a pipe with a large diameter. Between the walls of the pipes, an air cushion is formed that retains the heat of water in the main pipe. This method is often used for trenchless laying of an external water supply.

Pouring the pipeline with polystyrene concrete (foam concrete). Thermal insulation is a monolithic layer of lightweight porous concrete.

Wrap the water pipe with insulation. Climatic protection of polypropylene pipes and HDPE pipes can be carried out using polyurethane foam or dense foam. These materials are quite resistant to moisture, durable, and, most importantly, do not attract small rodents.

Water pipe wrapping with heating cable. The cable can be laid both inside the pipe and on its surface. Lay cable It stands either helically around the pipe, or in two parallel lines (heat from one line may not be enough). The most economical option is to wrap the cable with a wavy line.

Pressure increase in the water supply. The ability to increase the pressure of the pipeline is not available in all systems, however, this method is one of the most effective. The liquid in the pipes does not freeze at high pressure even in the absence of physical thermal insulation.

Systems that will be used for irrigation do not need additional insulation. Freezing water in an irrigation water supply is not scary, since it will be operated primarily in the warm season. But, when laying this type of pipeline, it is worth paying attention to its frost resistance, since in winter the very structure of the pipe material may deteriorate.