Polymer pipes are the best option for solving many issues related to the installation of a water supply system in an apartment. In today's market you can find a huge number of varieties of these products. Before you purchase any components for repair, you need to understand the properties of each type well plastic water pipes.

Content

Types of plastic pipes for water supply

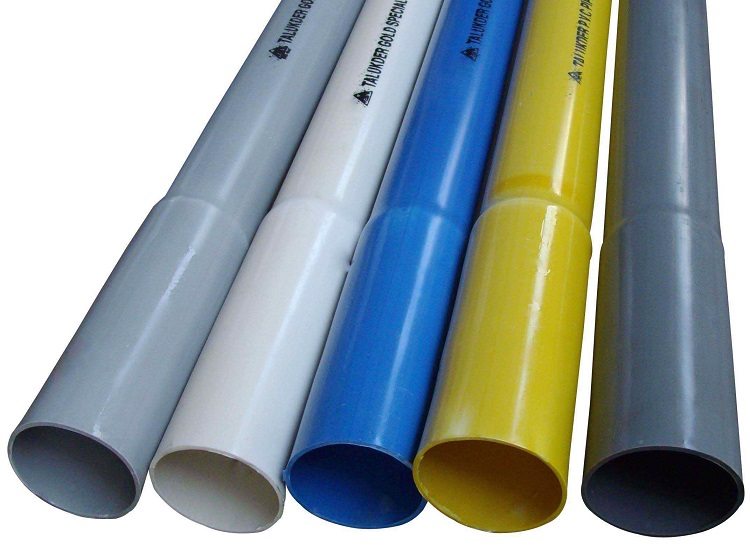

The assortment of plastic pipes is presented in several varieties. Each species has its own differences and advantages.

Pipes made of polyvinyl chloride (PVC or PVC). One of the first types of pipes that became widespread in the economy and industry. They have the lowest cost among other water pipes. They have a fairly aesthetic appearance, so they can be used even in open water supply systems. Most often installation of plastic pipes is carried out by welding or fittings, but products made of polyvinyl chloride can be mounted using the "cold" method. For welding, special plumbing glue is used, as well as rubber cuffs.

PVC pipes they are generally resistant to climate change, but exhibit better performance in cold environments. For laying a hot water pipe in domestic conditions, PVC is not recommended, since when heated to 50-60 degrees this material begins to melt. More suitable for hot water CPVC - chlorinated PVC. CPVC pipes perform well even in heating systems.

Polypropylene pipes (PP). Lightweight and durable pipes designed not only for water supply, but also for the "underfloor heating" system and central heating. One of the insignificant disadvantages of plastic polypropylene pipes can be called their inability to bend. For bends and turns of the structure, component materials are used: corners, tees.

Polypropylene is quite resistant to temperature changes due to its multilayer structure. PP pipes are mounted by thermal weldingcreating a very tight, almost monolithic joint. This means that using polypropylene pipes impossible to make a collapsible connection.

Helpful advice! When welding plastic pipes made of polypropylene, it is important to prevent overheating of the material. Plastic becomes brittle when overheated, so this connection will not last long. Dirt and water at the workplace can also impair the quality of the connection and shorten the life of the pipeline.

Pipes made of polyethylene (PE). Polyethylene is a very flexible material, so it is used for running water even in areas with increased seismic activity. The following types of polyethylene pipes are produced: high pressure (LDPE) and low pressure (HDPE).

Plastic pipes-LDPE is used in main pipelines, as a laying of casing pipes for wells.Due to the low density of high-pressure polyethylene, these types of pipes are not used in everyday life.

HDPE pipes, as a rule, are black (models with marking strips of blue color can be found). Black plastic water pipes are recommended for drinking water supply. Low pressure polyethylene becomes soft when exposed to hot water. In order to avoid network breaks, it is not recommended to use such pipes for heating systems and hot water supply.

Installation of plastic black pipes for water supply has several features. It is not recommended to carry out repair work at a temperature of less than +5 degrees, since polyethylene loses flexibility at low temperatures. If it is necessary to carry out the installation of polyethylene pipes in the winter, insulation is used. Installation of a polyethylene pipeline can be carried out by electric welding and using crimp (compression) fittings.

Cross-linked Polyethylene (PEX) Pipes. They are much better suited as piping for hot water than HDPE plastic pipes. Cross-linked polyethylene pipes are produced under pressure, resulting in improved material properties. Their installation is possible with the help of fittings - fittings. To reduce the likelihood of oxygen ingress into the pipes, it is recommended to create an additional coating with a diffusion barrier when laying them.

Pipes made of metal-plastic (PEX-AL-PEX). They have a multilayer structure. They are made on the basis of cross-linked polyethylene, inside the pipes there is a layer of aluminum (less often - copper) foil. The main ability that distinguishes metal-plastic pipes from other plastic models is the ability to maintain shape when bent. They also withstand high temperatures and atmospheric pressure, but can expand due to thermal fluctuations. When passing through metal-plastic pipes of hot water, their slight deformation is observed.

Which plastic pipes are best suited for plumbing?

Choosing plastic pipes for home and apartment is based on the functional features of the water supply. If you need to purchase plastic pipe for hot water, it is worth stopping the choice on polypropylene models. Cross-linked polyethylene also handles similar functions, but its cost is usually higher.

In addition to the type of plastic pipe, you should pay attention to its diameter when buying. The throughput of the entire system will depend on the correctly selected pipe diameter. The plastic pipe for the water supply must not have a diameter of less than 15 mm. A plastic pipe for water risers is usually used with a diameter of 25 mm.

Helpful advice! If the plan of the future water supply system has many turns and bends, do not purchase plastic pipes of too small a diameter. Because of this, problems with pressure and water supply can occur. In such cases, it is advisable to consider adding pipes with a slightly larger diameter to the wiring.

If you plan to install plumbing communications outside the building, then it is worth remembering that the plastic structure requires insulation. This procedure will significantly affect both the efficiency of the water supply system and its performance. What materials for insulation to choose depends on the depth of the pipe and the climatic conditions of the area.

Advantages and disadvantages of plastic water pipes

The main advantage of plastic is its durability. Unlike metal structures, plastic pipes are more resistant to external factors. They do not corrode, salt and other deposits are not formed on the pipe walls.Since plastic pipes have come into common use relatively recently, it is difficult to determine their exact life. Manufacturers declared a service life of a plastic water pipe of at least 50 years, subject to proper installation and operation.

The latest models of plastic pipes for water supply are made from organically pure material that does not have a negative impact on the environment. They do not impair water quality. Due to the low thermal conductivity of plastic, such plastic pipes used in heating systems and hot water supply systems help to maintain the heat of hot water. It is also noted that the wall density of such pipes tends to suppress the noise of the water stream.

The disadvantage of plastic water pipes can only be called the fact that not all types are suitable for the effective operation of the hot main. But given the fact that industry does not stand still, there are already plastic products on the market that can withstand temperatures of about 90 degrees. Therefore, when planning to carry out water supply, you only need to find out which pipes are suitable for solving your particular problem.

Plastic pipes are great for those who want a durable, easy to install and practical plumbing. Their service life significantly exceeds the warranty period of metal pipes, and installation can be carried out even at home without special training.