Polymers have penetrated almost all spheres of activity of modern man. Particularly in demand today is low-pressure polyethylene (HDPE). It has occupied a significant niche in the segment of sanitary equipment in the world market. Today, most of the pipelines and pipeline fittings are made from it. The advantages of HDPE pipes include ease of installation, it can be performed by one person due to the low weight of products made from polyethylene.

Content

Types of connections

PND pipe connections are of the following types:

- detachable. During operation, they can be disassembled. To create such a connection, steel flanges are used;

- one-piece. Disassembly during operation is not possible.

The last type of connection is made in two ways: by butt welding of polyethylene pipes and by welding of polyethylene pipes with couplings.

Installation of large-diameter pipelines is carried out using thermoresistive fittings, as well as by welding butt pipes. In any case, the connection is monolithic and, therefore, very reliable.

Do-it-yourself butt welding of HDPE pipes

Butt welding of polyethylene pipes requires the use of special welding equipment. But the simplification of the installation process leads to the absence of the need for additional details. Use this technology only for HDPE pipes the same diameter.

Helpful information! Butt welding of pipes PND only then it will turn out high-quality, when it will be done with one seam. This ensures equal contact strength of adjacent pipe parts.

Installation performed by butt welding of polyethylene pipes is the most versatile and efficient. When using it, the flexibility of polyethylene along the entire length of the pipeline is maintained. This process does not create any difficulties, regardless of the type of pipeline laid out by the project: open pipe laying, the traditional method or trenchless renovation.

Butt welding of polyethylene pipes with their own hands using a heating tool is performed as follows:

- first install the ends of the pipeline elements to be welded in the centralizer welding unit;

- after their alignment and reliable fixation, clean the ends of the pipes from dust and dirt with a cotton towel;

- then treat the surfaces to be welded mechanically using a trimming device. When you get uniform chips, the thickness of which will not exceed 0.5 millimeters, stop trimming, remove the device and use your hand to check the mutual parallelism of the ends;

- if you find that there is a gap between the surfaces to be welded that exceeds the permissible value, repeat the trimming operation;

- then with the help of a heating tool with non-stick coating heat the ends of the pipes to be welded;

- when the fusion of the ends reaches the highest phase, dissolve the surfaces to be welded and remove the heating element from the welding zone;

- Having done this, close the surfaces to be welded and begin to uniformly raise the pressure of the clamp until its value reaches the required value;

- seam withstand under the set pressure a certain period of time.

At the final stage, check the quality of welding of the HDPE pipe by the appearance of the burr, as well as by height and width.

DIY method for welding HDPE pipes

Welding performed by this method requires a special welding machine - a soldering iron, equipped with a set of special nozzles. Diameters of nozzles correspond to standard values of this parameter of fittings.

When welding PND pipes, fittings are used. They can have a different configuration: couplings, corners, tees. The surfaces to be welded are parts of the pipe and fitting. If this is your first time doing the work yourself, unsuccessful connections or skews can occur.

Helpful advice! Given the above, buy fittings with a margin.

Socket welding can be performed in cramped conditions where axial movement of pipes is limited. The heating of the polyethylene components is carried out by contact with a heated welding nozzle made of metal. Its design includes 2 screwing parts. The inner surface of the fitting is heated by the part of the nozzle, called the mandrel. The other half is called a sleeve. A pipe is inserted into it. In order to insert the nozzle into the hole of the soldering iron, the mandrel and sleeve must be unscrewed. Socket welding technology involves the following steps.

Fitting and welding nozzle preparation

Before starting the connection, you need to do some preliminary work.

- Cutting the pipe with special scissors to the desired size. It is necessary to perform this operation so that the section of the cut is strictly perpendicular to the longitudinal axis of the pipe.

- Cleaning surfaces subjected to welding of polyethylene parts. To exclude additional cooling, the free ends of the pipes are closed with plugs.

- Cleaning the surface of the welding nozzle from the remnants of previously performed work.

After completing these preparatory operations, heat the nozzle to a welding temperature. The fact that the value of this parameter has reached the required value, you will be signaled by an indicator that is installed on the body of the soldering iron.

The polyethylene pipe is inserted into the sleeve until it stops, and the fitting is put on (also to the end!) On the mandrel. Due to the difference in diameters, these steps will require some effort from you. Everything needs to be done quickly, but carefully. Below is a table of welding times. It contains data on pipes with the most popular outside diameters.

Table 1

| D, mm | Loading seconds | Tsoed., Seconds | Cool., Minutes |

| 16 | 5 | 4 | 2 |

| 25 | 7 | ||

| 40 | 12 | 6 | 4 |

| 50 | 18 | ||

| 75 | 30 | 10 | 8 |

Here: Dnar is the outer diameter, Tnagr is the heating time, Tconn. - connection time, Cool. - cooling time.

During the introduction of the pipe and putting on the fitting until it stops, the excess layer of their surfaces is melted and squeezed out. As a result, the so-called burr is formed on the edges of the parts to be welded - an annular bead.

When the fitting and pipe reach the stop, the pressure should be stopped. This is a very important requirement. Failure to do so will result in a connection failure. And rely on the fact that an increase in resistance to the advancement of parts will signal the achievement of emphasis, especially not worth it. Due to the fusion of the material, it will increase slightly, and you may not notice it.

Helpful advice! In order not to miss this moment, put on the pipe with a felt-tip pen at risk.

The final stage of the methodology presented, how to weld an HDPE pipe with your own hands in a sleeve method, is very important.A few seconds after the stop is reached, remove the parts from the nozzle. Then insert the pipe into the fitting so that it abuts against the ring roller. Do not expose the resulting solid part to cooling or any other sudden impact until it cools.

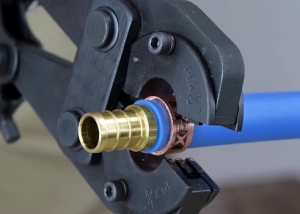

Electrofusion welding of polyethylene pipes

To implement this type of connection, a coupling is used, equipped with embedded electric heating elements. From an economic point of view, HDPE pipe welding performed by this technology is less profitable compared to butt welding.

However, this method is very popular due to the fact that the passability of the pipes does not decrease, since no burrs are formed on their inner surface. And in a limited space, when it is not possible to place the overall unit for welding, there is no alternative to this method.

The connection of two HDPE pipes in a straight section is most often done using a simple electrofusion coupling. But saddle bends and electrofusion tees are also suitable for this operation. Below we will talk about how to weld HDPE pipes with your own hands using exactly the electric coupling. In addition to hands, you will need an electrofusion welding machine. Welding is carried out by a polyethylene welded fitting.

This product has some features. Special spirals are built into it, serving as heating elements. The part of the fitting body melted from the heated spiral will connect to the plastic of the parts that form the pipeline. In this case, the spiral remains forever in a monolithic seam. This technology creates a connection of high strength. However, it is relatively expensive. Most often used in the assembly of gas pipelines.

Carrying out electrofusion welding of HDPE pipes provides for the following actions:

- using a special cutter, the pipeline is cut into pieces of the right size;

- cleaning from dirt and degreasing the inner surface of the electrofusion coupling and the welded surfaces of HDPE pipes;

- drawing on pipes pipes to control the depth of input;

- to exclude additional cooling, the free ends of the pipeline are closed with plugs;

- special wires connect the welding machine to the electrofusion coupling and press the "Start" button on the machine;

- the end of welding is carried out by automatically turning off the device. You can use the resulting compound in at least an hour.

Important! A prerequisite for high-quality electrofusion welding is the immobility of the parts during the heating and cooling processes.

The following requirements are imposed on welded joints:

- the weld should be located not lower than the outer level of the pipe surface;

- the offset of the welded segments relative to each other should not exceed 10 percent of the wall thickness of the polyethylene pipe;

- the height of the high-quality weld bead on pipes whose wall thickness is not more than 5 mm inclusive, should be up to 2.5 mm. If pipes with a wall thickness of 6 ... 20 millimeters are connected, its height should not exceed 5 mm.

When choosing a connection method, consider the operating conditions of the created pipeline. Only then will the whole system function reliably for a long period of time.