Plastic pipe for gas is a relatively new type of equipment. It is increasingly being used to supply and transport fuel material on a private home or in commercial buildings. This equipment has many advantages, however, before using it on your site, you should familiarize yourself with certain product features and installation instructions.

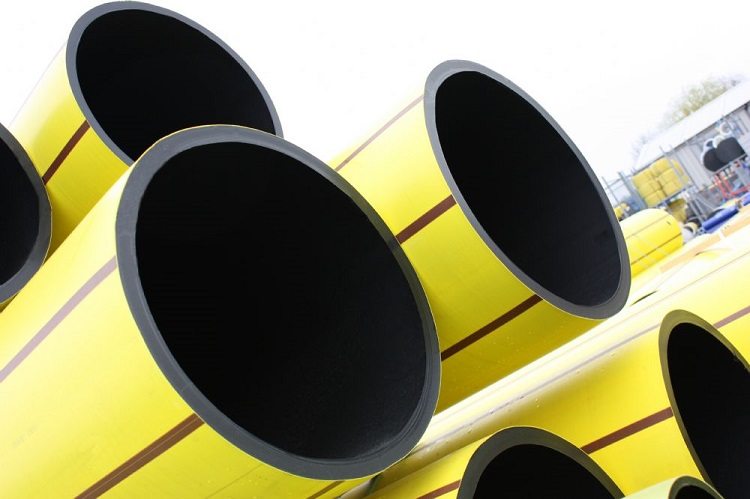

Plastic pipes for gas have many advantages over metal pipes, but it is allowed to lay them only underground

Content

- 1 High-quality gas pipeline for a private house: what it consists of

- 2 Plastic benefits

- 3 Features when comparing with steel counterparts

- 4 Types of Plastic Pipes

- 5 Pros and cons when comparing plastic and polyethylene pipes

- 6 What to consider during installation

- 7 Methods of connecting elements of communication systems

- 8 How to weld pipes

High-quality gas pipeline for a private house: what it consists of

Gasification in a private cottage is a complex and time-consuming process. It requires maximum accuracy, accuracy and professionalism. If it was necessary to build or repair gas communications, it is better to resort to the help of specialists. It is very important to observe all safety measures and make sure that the structure and its installation / repair comply with all fire safety requirements.

The gasification scheme in the house includes such elements:

- gas holder - a special tank for storing gas;

- pipes for supplying fuel;

- gas boiler, water heater, gas stove, fireplace or other consumer devices.

When arranging this system, the correct one is important gas pipe selection. It depends on what working volumes of the pipeline you are counting on, what type, condition of the soil and corrosion activity in the section, as well as what amount you are counting on.

Helpful advice! It is better to use the services of specialists to determine from what material the elements of the pipeline for gas should be made - from metal or plastic. For this, there are certain gasification requirements and state standards.

The gas supply to the house must be carried out in compliance with safety measures, and the choice of pipes here plays an important role

Plastic benefits

Recently, communication equipment for plastic gas has been very popular. The material itself was invented not so long ago, and in the field of construction and repair work they began to use it even later. However, now it is in demand, as it has advantages, compared with analogues of metal.

Firstly, pipes made from it are not susceptible to corrosion, which is the main weak point of iron products. Plastic pipes for the gas pipeline do not need additional protection and insulation also because they do not conduct current, are resistant to the negative effects of the environment, various organic and chemical aggressive substances. In addition, they do not need cathodic protection.

Secondly, the plastic gas pipe functions successfully even with frequent changes in temperature, but not in extreme conditions.

In addition, such a pipe is very durable and strong, which is ensured by a homogeneous structure and operational characteristics of the material itself. Warranty period of use reaches 50 years.

Plastic gas pipes are convenient and easy to install, they are easy to transport to the place of work

Another plus is versatility. Due to its ductility, pipes can be used in the construction of gas pipelines of the most complex devices and in the most inaccessible places, adverse environmental conditions.

Features when comparing with steel counterparts

In addition to the advantages, any product has certain disadvantages, and plastic pipes for the gas pipeline are no exception. Before installing them, note that it is impossible to install such structures:

- Above ground and above ground. Plastic pipes for gas are intended for underground utilities located inside the soil.

- In areas of increased seismic activity. This applies to territories where the level of activity reaches 6 points.

- Within the city, in high pressure gas zones (in gas pipelines of categories 1 and 2).

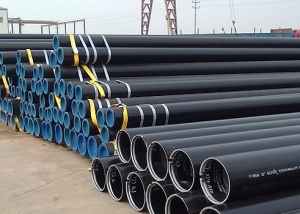

- In enclosed spaces, residential, commercial and industrial buildings, collectors. It is customary to use mainly steel structures here.

- A plastic pipe for gas is inferior to a metal one in strength characteristics.

If we compare plastic pipes for a gas pipeline and steel communications, then we can notice some significant differences:

- Cost. Since steel pipes require additional electrical insulation and protective layers, installation and maintenance takes more time and money. And the prices for steel are slightly higher than for plastic products.

- Weight and transportation. Steel equipment weighs much more, which complicates its transportation. In addition, plastic products are transported in bays, which makes them more compact.

- Universality. If everything is simple with a plastic pipe for gas in a private house, then steel products must be used strictly taking into account temperature, landscape conditions, operational parameters. Depending on this, the desired thickness is selected, design features.

- Installation. Steel piping is somewhat more difficult to install than plastic.

Despite all the advantages of plastic gas pipes, it is forbidden to use them in high pressure gas pipelines

When choosing the right material, be sure to consider the above differences and features.

Types of Plastic Pipes

Depending on the material, plastic pipes come in many forms. Each variety has its own characteristics and specifics, which must be taken into account when laying communications.

The first type is polyethylene pipes of low and high pressure. There are two brands of such pipes, visually distinguished by a colored stripe. Gas marked in yellow. This type of equipment is characterized by affordable price, light weight, elasticity. This option is also suitable for arranging communication systems for cold water supply, as well as sewage.

The second type is PVC pipes. This is a more stable design, but its use in water supply systems is not recommended, because when interacting with individual substances it releases chloroethylene toxin. But for sewers, they are quite suitable as a replacement for cast-iron pipes.

A safer option is polypropylene. It is practically inactive when interacting with chemicals. This gives him the same advantage that metal-polymer pipes have - multifunctionality. That is, it can be used in various types of communication systems, including gas supply.

Pros and cons when comparing plastic and polyethylene pipes

Transporting pipes made of plastic or small diameter polyethylene is equally simple. They are produced in bays of 50-500 m and weigh 2-4 times less than steel counterparts.

Butt welding of gas plastic pipes is also cheaper than in the case of steel. This does not require additional consumables. And the process itself is much simpler and faster. You can use thermistor couplings, which will also simplify the installation procedure. Such a pipeline can be laid by pulling. And he will serve for a long time, without requiring frequent intervention and repair, and also thanks to the smooth and elastic inner surface. Thick-walled polyethylene pipes can be used for a gas pipeline of the third and sometimes even second category.

However, there are some differences between these types of material:

- at extremely low temperatures gas polyethylene pipes lose their operational capabilities and possible damage;

- PVC pipe is more durable and safe in terms of reaction with chemicals;

- polyethylene is not resistant to the negative effects of ultraviolet rays, so you need to install a plastic pipe for gas underground, and not in an open space or in a lit room. Otherwise, this can lead to a decrease in the fate of service and negative consequences. But for PVC pipes, this restriction is not relevant;

- It is possible to lay polyethylene pipes outdoors only in the soil in order to protect the equipment from mechanical damage, while a metal-plastic pipe has greater strength.

A pipe made of metal-plastic has greater strength than HDPE, and it can be used where there is no way to carry out hidden laying of the pipeline

What to consider during installation

Before starting installation work, make sure you can use plastic pipes for gas in your area. For this, attention should be paid to some points.

The gas pipeline from polymer pipes can only be laid by a hidden method. Polyvinyl chloride has a low percentage of expansion, so feel free to install pipes in concrete or specially equipped adits. However, not too tight, but rather with the use of insulating soft material, so as not to damage the pipe.

Helpful advice! Remember that the less you use fittings, various connecting and butt elements, accessories, the more stable the pressure will be. And this means that energy costs for transporting fuel are also reduced.

For pipe connections Use pressed or crimped fittings. Draw up a plan in advance to build a plastic gas pipeline. Make sure that it is approved by the appropriate authorities. Better not try to do the work yourself, but contact a specialist for help. Remember that gas supply and transportation equipment is a dangerous thing and improper installation or maintenance can result in tragic consequences for you and your loved ones.

Methods of connecting elements of communication systems

The plastic pipe should be mounted underground or in another medium (by a hidden method). Connect the pipes mainly by welding.

Plastic pipes are welded using a special welding machine, its type depends on the selected welding method

There are three main ways to weld:

- Electrofusion. The plastic gas pipe melts under the influence of current and connects to the other using a fitting. This technique is used for polypropylene and polyethylene gas communications.

- Butt. This method connects a plastic pipe of all kinds with a diameter of 5 to 16 millimeters.

- Vrastrub. This is a type of welding, intended mainly for the repair and installation of sewer and water supply systems. They connect pipes with a diameter of 15 to 90 millimeters.

As for the plastic pipes for gas in a private house made of polyvinyl chloride, they are interconnected with glue.You should not be skeptical of this type of fastening, as modern technology allows us to produce durable glue that provides a durable connection for several decades. This method is more convenient and does not require special equipment, providing special conditions for the soldering process.

How to weld pipes

To correctly and reliably interconnect gas communication elements, clearly follow the instructions for welding a plastic pipe butt. This method allows you to quickly connect system elements. Thanks to it, even a large pipe with a diameter of 50 to 120 millimeters can be processed without any difficulties.

For this you need a special welding machine. There are different types of equipment:

- with hydraulic drive;

- with electric drive;

- on program management.

Which one to choose depends on how much you expect, what working conditions are provided and, of course, the volume of work matters.

If you have purchased the necessary equipment, you can proceed directly to work.

- first install the ends of the parts in the welding machine. Make sure that the fixation is good and smooth;

- then place the heating element between the ends of the pipes to be joined. Wait until the first bur is formed - that is, when the polyethylene begins to melt;

- remove the hot plate and press the ends against each other with the necessary effort. After the process is complete, allow time for the pipe to cool.

Helpful advice! Do not try to cool the plastic pipe by applying water. The temperature should drop to the level of the environment naturally.

Plastic pipes for gas is a modern material that has a lot of advantages. But gas pipelines have their own specifics, so these pipes are not allowed to be used on all sections of the gas pipeline. Therefore, it is worth consulting with specialists before deciding whether to lay or upgrade the system.