The pipeline used for casing wells is made of different materials: alloy and carbon steel, asbestos cement, polymers. For a long time, steel pipes were used. Today, plastic products that have a long service life and high environmental friendliness are a good alternative for these purposes (especially when equipping mines up to a hundred meters).

Content

Types of Plastic Casing

Plastic casing is used because of the shedding of the walls of the wells, especially when drilling loose soil layers. Polymer products have unique performance characteristics, they are durable and lightweight, and also have a low cost.

The production of plastic pipes for wells is based on the use of several types of polymeric materials. Most are produced from low pressure polyethylene (HDPE) and polyvinyl chloride (PVC) by thermoplastic extrusion. Since the process is automated, high accuracy of products and optimal consumption of raw materials are ensured.

PVC-U pipes have high strength and resistance to chemicals. They are not heavy, and the threaded connection is equipped with a sealing ring.

Note! The disadvantages of such products are the inability to use at low temperatures and low ductility.

Polyethylene casing pipes are quite flexible, withstand significant internal and external mechanical pressure. Such products allow laying with a small bend.

Plastic pipes for wells are classified into two types:

- threaded;

- without thread.

The first type of pipe is connected by a thread that runs on the inside of one end of the product and on the outside of the other. It can be of tape type or type of cylindrical trapezoid with a pitch of 6 mm and a depth of 2.2 mm. Such a thread increases the tightness of the joint. Threaded connection takes place using patch couplings.

Polymer pipe application options

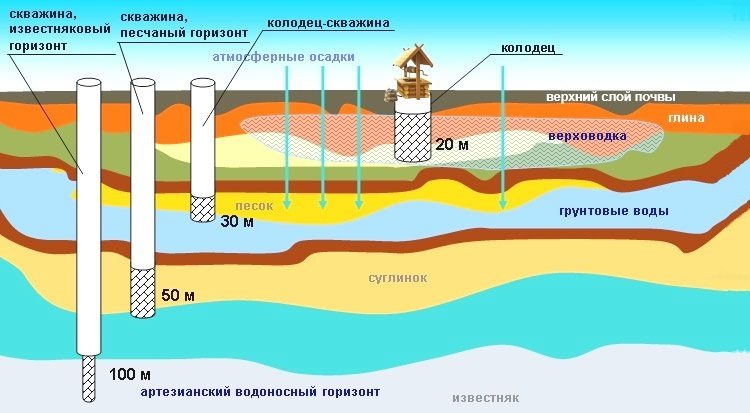

There are several types of water layers in the ground:

- artesian waters;

- groundwater;

- top layer.

The top layer is located closest to the surface, the depth of which can reach up to 5 meters. The main source of water in it is precipitation, which determines the quality that does not meet the standards. This layer fluctuates throughout the year. For wells in it, plastic pipes may well be used.

When choosing pipes, you should first determine the depth of the future well: for artesian wells, plastic pipes should not be used

Groundwater is located at a considerable depth - usually up to several tens of meters. Since water passes through multilayered layers of clay and sand, it is much cleaner.

Since water is of high quality in such a layer, and the cost of drilling is low, a large number of underground wells are located in it. The most commonly used plastic pipe with a diameter of 125 mm.

At the level of artesian water is the highest quality water - the depth is 40-250 m.At such depths, wells are infrequently made. Soil layers exert a high pressure on the pipe, which requires the use of products of increased strength. In this case, pipes made of polyethylene and PVC are suitable, but it is better to give preference to stainless steel.

PVC casing pipes can be with different wall thicknesses. The diameter of the casing element and the main pipe depends on the well’s ability to deliver the required amount of water for a certain time, pump power, and water consumption calculations.

Characteristics of casing HDPE pipes

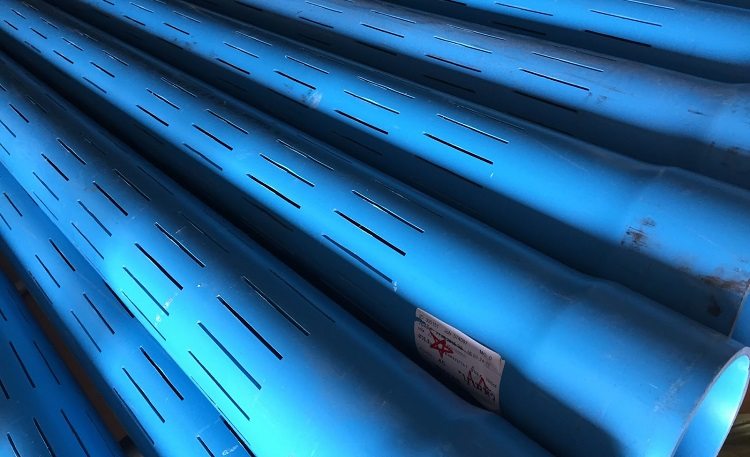

Pipes made of low-pressure polyethylene for casing wells are most often produced in black or blue.

Note! The main operational properties of the well are service life, productivity and water quality, which is explained by the absence of factors of all kinds of pollution.

Upsetting HDPE pipes have an outer diameter from 90 to 180 mm, wall thickness from 7.3 to 14.0 mm. The standardized length is 4 meters, but any pieces of products from one to 12 meters can be delivered.

HDPE pipes have high impact strength, chemical resistance and the necessary density. The smooth surface prevents the accumulation of precipitation, which lengthens the operational life.

The symbol for a plastic pipe for a well includes such characteristics:

- name of material;

- type of pipe;

- value of the dimensional relation;

- outer diameter (nominal value in mm);

- wall thickness (nominal value in mm);

- application area;

- technical conditions.

Such products can be used during the drilling of oil and gas wells or in the search for water, minerals.

Advantages of plastic casing pipes

Upsetting plastic pipes for the well are environmentally friendly. Smooth inner surface provides low resistance to water flow. The pipeline is also resistant to aggressive environments, corrosion and chemicals.

The casing design has high annular rigidity and strength. It does not narrow and is not subject to structural deformations due to atmospheric changes or after some time.

The low weight of plastic products for wells reduces the duration and simplifies installation work. In addition, they have a low cost compared to analogues of other materials and are easy to maintain.

You can store products in open areas, in awnings or in rooms without heating. The laying height is up to 2-3 meters depending on the shelf life. For transportation of casing pipes for wells with a diameter of more than 22.5 cm, mandatory packaging is not provided.

Installation of plastic products for wells

Well casing is performed during its drilling or immediately after completion of this process.

Plastic pipes are lowered into the shaft so that no wall shedding occurs. The pipeline is fixed in the middle of the shaft by pouring cement between the installed pipe and the wall of the well.

Pipes are installed in the well during drilling or immediately after it to prevent channel walls from sprinkling

The method of obtaining the barrel depends on the type of docking. Non-threaded casing plastic pipes used for the well are connected with a sleeve or socket. An adhesive solution is applied to the outer surface of the pipeline, as well as inside the connecting element. Next, the elements are joined.

Note! As the weight and loads gradually increase, this method is used only at shallow depths.

This type of casing with plastic pipes is cheaper, but it is less reliable. For deep shafts, it is better to use welded couplings.They melt from the inside, and the pipeline from the outside, by heating, and then connect. The resulting joint is durable and tight.

With a threaded connection, the presence of internal and external threads at the ends of the products is assumed. If only external threads are cut, a coupling is required for the connection. The reliability of the joint affects the cleanliness of the rising water, so it is better to use threaded pipes.

Plastic pipes for casing wells are widely used due to their low weight and ease of installation. However, it should be borne in mind that according to SNiP their use at great depths and with a significant water consumption is not allowed.