Corrugated products are the most famous and popular version of electrical pipes used in modern energy. They are successfully used for the formation of cable lines laid in hidden concrete and hollow structures. In addition, on the basis of electrotechnical corrugated pipes, power supply and control networks for machines with moving mechanical components are created.

Content

Varieties of material

The idea of laying a cable in pipes cannot be called a new one. But only earlier, for this purpose, the products of metal pipe rolled from steel, aluminum or copper were used. But the plastic pipes made of polyvinyl chloride (PVC) and low-pressure polyethylene (HDPE) that appeared almost completely replaced them. However, in some cases, regulatory documents require cabling in steel pipes for electrical wiring.

HDPE corrugated pipe. Such products are characterized by high mechanical strength and ability to withstand the effects of low temperatures. Therefore, they can be mounted both open and hidden. Today, two-layer pipes are also produced: the inner layer is made of less durable high-pressure polyethylene, and the outer one is already made of HDPE.

Corrugated PVC pipe for cable. The strength characteristics of these products are at a fairly high level. For their production, a special modification of PVC is used, which contains some specific additives. When a short circuit occurs, the pipe does not burn, does not support combustion, but only melts. The melt obtained during this process isolates the damaged area, thus preventing the spread of fire.

PVC electrical pipes do not burn, so they are often used for laying open wiring in residential premises

Steel electrical pipe. As with previous products, in its design there are sections with a large diameter and with thick walls, which are interspersed with segments of a smaller diameter and with thin walls. The presence of the latter elements causes inability corrugated steel wiring pipe stretch a lot. But flexibility corrugation metal, especially of small diameter, is on top.

Today, PVC products are most in demand, and there are good reasons for this.

Advantages and types of corrugated pipes

Polyvinyl chloride pipes for electrical wiring are used for laying computer, telephone, television and electrical networks in the open air and indoors.

Important! It is not recommended to carry out installation at air temperatures below 5 ° C.

Compared to similar metal products, corrugated electrical PVC pipes The following indisputable advantages are inherent:

- if the cable insulation layer is damaged, the risk of electric shock is excluded;

- ease of installation and laying;

- lack of need for protection against corrosion and the organization of grounding;

- the cable can be laid not only in rooms with high humidity and underground, but even under water.

- long service life and low weight;

- the ability to bend the material and the lack of need for welding greatly facilitates the installation of PVC corrugated pipes for electrical wiring;

- provide reliable protection of electrical wiring, which is a guarantee of uninterrupted operation of the network.

If there is a need for wiring inside the walls or floor, you need to use heavy pipes that can withstand heavy loads

Depending on the maximum allowable load, these products are divided into the following groups:

- superheavy. Able to withstand a load of 1250 N / 5 cm. They are allowed to be laid underground and are used in those organizations where increased requirements are imposed on the safety level of wiring - child care facilities, hospitals, cinemas, etc .;

- heavy, FH series. The maximum permissible load is 750 N / 5 cm. You can use such a PVC pipe for laying the cable in a concrete screed when monolithic construction is carried out;

- lungs, a series FL. Maximum load 350 N / 5 cm. They are used inside buildings of any type. Allow open laying on walls, ceiling and floor. This is the best option for false ceilings.

Inside the tubular channel of the product of each series, a broach can be placed - a metal wire with a diameter of 0.9 mm. With its help, the process of laying the cable in a flexible sleeve is greatly simplified. Therefore, in order not to encounter unnecessary difficulties during installation, before purchasing, take an interest in whether there is such an accessory in the model of corrugated pipe you like. In GOST 51613-2000, which manufacturers should be guided by, this requirement is not specified.

Corrugated Product Specifications

When purchasing a polyvinyl chloride corrugated pipe for electrical wiring, you must remember that the catalog indicates the outer diameter, which is several millimeters larger than the inner. Therefore, choose the electrical corrugation with a value of this parameter that exceeds the cross-section of the wiring harness.

The choice of the diameter of the corrugated pipe depends on the cross-section of the cable that will be laid in it

What are the inner and outer diameters of corrugated PVC pipes, you will find out by reading the data presented in the table.

Table 1

| Inner diameter mm | Outer diameter mm | Bay length, meters |

| 50,6 | 63 | 15 |

| 39,6 | 50 | 15 |

| 32,5 | 40 | 15 |

| 24,3 | 32 | 25 or 50 |

| 18,3 | 25 | 25 or 50 |

| 14,1 | 20 | 50 or 100 |

| 10,7 | 16 | 50 or 100 |

Advice! To select the profile of the desired diameter, it is necessary to take into account the fact that the space allotted for cables should not exceed half the volume of the cavity of the corrugated sleeve for electrical wiring. Otherwise, pulling the harness of the occasions will be impossible or difficult.

In the presence of a broach cable, depending on the type of equipment connected to the mains, the optimal value of the diameter of the corrugated pipe is:

- if the power is supplied indoors to the lighting fixtures, 16 mm will be sufficient;

- for laying wiring to switches and sockets, you should purchase an electrotechnical corrugated PVC pipe with a diameter of 20 mm:

- in the interfloor spans and in the walls of buildings, it is recommended to lay corrugated PVC electrical pipes for a cable with a diameter of at least 40 mm.

For the convenience of pulling wires, you should choose a corrugation with a probe, but its presence should be taken into account when choosing the diameter of the pipe

Specifications for corrugated PVC hoses are presented in the following table.

table 2

| Material | Self-extinguishing polymer composite |

| Fire resistance, ˚С | Up to +650 |

| Insulation Resistance, MΩ | 100 |

| Dielectric Strength, V | 2000 |

| Operational interval, ˚С | -25 |

| Installation temperature, ˚С | -5 |

| Degree of protection | IP55, IEC 529-89 (GOST 14254) |

| Colour | Gray, RAL 7035 |

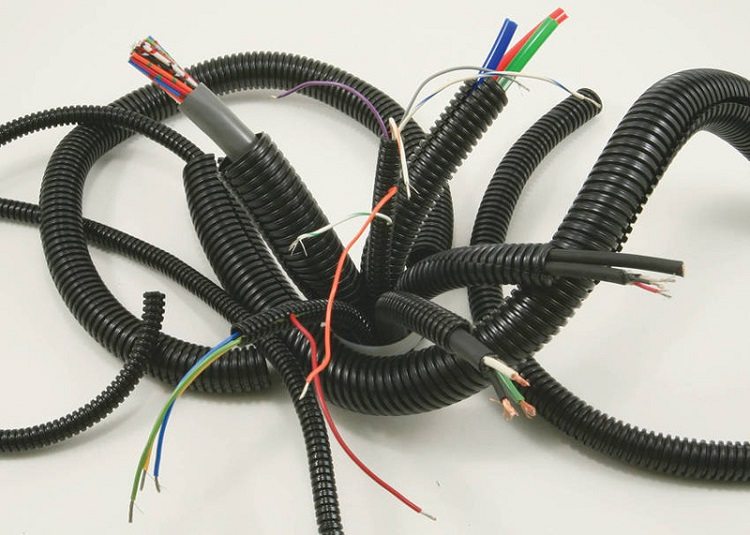

To facilitate the selection of corrugated PVC pipes suitable for future operating conditions, manufacturers produce these products in different colors:

- in black it is recommended to lay general-purpose cable lines;

- blue corrugated pipe - telecommunication and communication systems;

- power cables are laid in a red corrugated pipe.

Installation of electrical corrugated pipes

Direct sections of the highway are connected using special couplings. The branching of the wiring is carried out in the mounting boxes. For fastening pipes to various surfaces, brackets and clips designed for different diameters of the corrugation are used.

Fix the electrical pipes with plastic clips of various shapes, their size is selected in accordance with the diameter of the corrugation

The requirements for the placement of fasteners are as follows:

- for products with a diameter of 16 mm, the distance of the brackets (clips) from each other is 35-40 cm;

- corrugated pipes with a cross section exceeding 32 mm require more frequent fastening - up to 25 cm.

Before starting work, it is necessary to mark the places where the pipe ends near the shields will be placed. Then the route of the route is planned, and the attachment points are selected. After that, the location of the junction boxes is determined.

Route the cable in corrugated pipes for electrical wiring in the following sequence:

- Blow out the electrical sleeve with compressed air.

- Cut precisely measured length. If there is a broach cable, have a bite and fix it so that it does not go into the cavity of the pipe.

- Attach the cable to the protruding end of the metal broach and pull it from the opposite end of the corrugated pipe.

- If you plan to lay several cables, fasten them with electrical tape along the entire length at regular intervals and pull them together.

Good to know! In the same way, a cable is laid in a steel pipe for electrical wiring.

Styling requirements

The main points of this procedure are indicated in GOST 50827-95. But many years of experience in the use of electrical corrugated pipes allowed us to formulate additional recommendations for the correct installation of these products.

Cables for different purposes do not fit in one pipe, for each type of network a corrugation of a certain color is used

Let's consider some of them:

- Networks for various purposes should not be laid inside one pipe.

- electrical wiring in a wall-mounted corrugated pipe is carried out at the final stage. First, the pipe must be fixed, then pour the solution and allow the surface to form.

- Use a transit box to extend the length of pipe. Install it in the center of the channel.

- the length of the working section of the pipe should be less than 25 meters.

- Install a UV-resistant model outdoors.

Corrugated pipes until widespread. However, the presence of undeniable advantages can soon lead them into the leaders of this segment of the global market.