Polymer tubular products continue to displace metal products in all applications. Dimensional steel structures are being replaced by lightweight smooth and corrugated PVC pipes. Reasonable price and high technical characteristics make these plastic pipes one of the most popular products in the field of construction and household. They can be used not only for water supply, but also for electrical needs.

Content

Specifications of PVC Corrugated Pipe

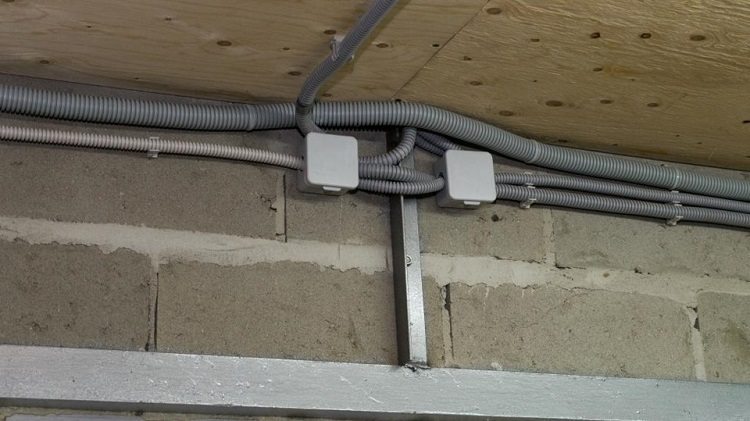

Properties corrugated drainage pipes made of plastic materials give a lot of opportunities when performing repair and installation work. Polyvinylchloride corrugated pipes are indispensable for laying electrical networks of various voltages, communication lines. PVC products have excellent flexibility, which allows them to be installed without special tools and equipment. Corrugated PVC pipes meet all modern norms and quality standards.

Corrugated PVC pipes have the following advantages:

- Absolute incombustibility. Polyvinyl chloride does not ignite under any conditions;

- High degree of isolation. In protective channels from polyvinyl chloride, the probability of the appearance of stray currents and pickups is eliminated. Due to this quality, several cables can be laid in one PVC channel.

- Easily amenable to various installation methods. PVC pipes can be joined by high-temperature welding, as well as using special adhesive solutions.

- Environmental friendliness. PVC material does not provoke allergic reactions and is generally completely harmless to humans.

- Ease. The system of corrugated PVC pipes does not require additional support, i.e. application of supporting reinforcement.

- Corrosion-resistant properties. Installation of corrugated pipe structures is possible in damp rooms and environments. PVC are not susceptible to corrosion and aggressive chemicals.

Important! Despite the many positive qualities of PVC pipes, it is forbidden to install them as cable channels on flammable substrates. If it is necessary to install electrical wiring, for example, on a wooden base, metal sleeves are used to protect the channel.

The installation of electrotechnical corrugated polyvinyl chloride pipes can be carried out both in an open way and under decorative panels, under drywall, inside the floors of a building. Can be laid in concrete screed.

Varieties of corrugated PVC pipes

Polyvinyl chloride corrugated pipes are produced mainly for laying electrical cables and for sewage. There is a classification of products by degree of strength:

- lungs (symbol - “L”);

- heavy ("T");

- superheavy.

Light electrical corrugations are very flexible, which is convenient when installing complex systems. But these corrugated PVC pipes are not recommended for use outside the building, since their life is affected by ultraviolet radiation.Heavy corrugated pipes are characterized by increased strength, they can be laid in the ground. Superheavy pipes are rarely used in households. Most often they are used in public places with increased requirements for the security of the system (schools, hospitals).

The production of non-combustible electrotechnical corrugated polyvinyl chloride pipes with a probe is also common. A probe (cable) helps to optimize the installation process. It is made from durable metal wire. Electrical pipes with the probe are connected according to the established plan, after which the ends of the electric cable and cable are connected. To get the cable inside the corrugation, it is necessary to pull the probe from the opposite end of the pipe. It takes several times less time to install a system equipped with a probe.

Helpful advice! When laying wiring in electrical pipes with a probe, a cord or wire can be attached to the edge of the probe and the cable to be conducted. This will make it possible to extend, if necessary, additional technical power lines after installation.

An important factor in choosing corrugated pipes simple and with a probe is their diameter. The cable inside the corrugation with the probe should not be laid too tightly, therefore, when choosing a pipe, you should be guided by the following tips:

- for laying a cable to lighting devices in the room, a PVC pipe with a diameter of 16 mm will be enough;

- if you want to lay wiring to outlets and switches, you should purchase a pipe with a probe with a diameter of 20 mm;

- corrugated pipes with a diameter of at least 40 mm are laid in the walls of buildings and in the spans between floors.

Use of corrugated PVC pipes for drainage

Light water pipes are not suitable for water drainage systems. For drainage, special types of PVC pipes are used - single-wall or double-walled corrugated pipes. Multilayer products have a smooth surface inside. The ring stiffness in these products is maximum, which makes the drainage system strong and safe. Pipes of this type are divided into several classes, depending on the structure and rigidity of the material. Drainage pipes can be marked SN2, -4, -6, -8, and the strongest are designated as SN16.

It is necessary to choose a pipe according to the stiffness class, focusing on the laying depth of the system:

- flexible corrugated pipeshaving a single-layer structure of brand SN2, are laid to a depth not exceeding 2 m. Single-layer pipes SN4 can be operated at a depth of up to 3 m;

- double-layer corrugated PVC pipes for drainage with SN6 stiffness are laid in the soil no deeper than 4 m;

- Rigidity pipes of classes SN8 and SN16 are designed for deep installation. They are able to function normally at a depth of 8 to 10 m.

There are also drainage pipes with an additional filter sheath. Geofabric or coconut fiber is used as a filter. A protective layer is necessary so that the drainage pipes are not clogged with particles of soil, sand, clay or silt. Pipes of types SN8 and SN16 are available without filter shells.

Helpful advice! With the device of shallow drainage, it is also possible to use pipes of increased rigidity. In this case, an increase in the service life of the drainage system is guaranteed.

In addition to corrugated pipes, the drainage system uses connecting fittings and drainage wells. Wells are arranged at the intersection of structural elements, with a change in the angle of inclination of the pipeline. Wells are needed for easy access to corrugated pipe connections for drainage to easily repair or clean.

Corrugated PVC and HDPE pipes: what is the difference

To decide which is better - corrugated PVC or HDPE pipes, you need to know for what purposes the planned design will be used.

Two of these types of polymers have different properties, and are equally successfully used to solve different problems. Both PVC and HDPE are durable materials, and with proper operation they can last up to 50 years. Both types of plastic pipes can be used to transport aggressive chemicals: oxides, acids, alkalis, salts.

Pipes made of low-pressure polyethylene (HDPE) are best used to protect low-voltage networks, open networks on the street, wiring in the ground, pressure and pressureless sewers, and arranging drainage. To protect high voltage electrical cables, only smooth-walled HDPE pipes with a rigid structure are allowed. For indoor and outdoor wiring of residential and industrial buildings, it is recommended to use only corrugated PVC pipes.

Polyvinyl chloride is a self-extinguishing material, while HDPE has a low flame resistance. Polymers like HDPE do not contribute to the spread of fire, but point fires occur in such systems. Technical characteristics of PND allow the material to tolerate low temperatures well, so it can be used for use in difficult weather conditions. PVC begins to deteriorate at low temperatures (from -10 ° C), and the structure of polyethylene does not break even at -60 ° C.

HDPE corrugated pipes have a lower cost, however, their installation may require additional costs. The PVC pipe is mounted by butt welding or using electric couplings, which provides a better result.