Corrugated stainless steel pipes (or the so-called "Cofulso pipes") have been known for quite some time. They were invented in Japan at the end of the 19th century. Since the country is located in a seismically active zone, these communications, which have rubber flexibility and steel strength, came in handy. Soon they began to manufacture them in Germany and South Korea. The latter is currently considered the leader among manufacturers of flexible stainless steel pipes. In honor of the leading company for the production of these communications, they received a second name.

The properties of stainless steel pipes allow them to be used to create engineering networks and other communications

Content

Production Process and Specifications

Previously, polypropylene and metal-plastic constructions, as well as pipes from cold-rolled steel sheets, were used for plumbing and heating systems. However, flexible corrugated pipelines are rapidly gaining popularity and are gradually replacing them. They are made of high quality stainless steel with the addition of nickel, chromium and carbon.

It is interesting! The concentration of additional components for the manufacture of products is calculated with extreme accuracy, which ensures the resistance of the corrugated pipe to corrosion and a long service life.

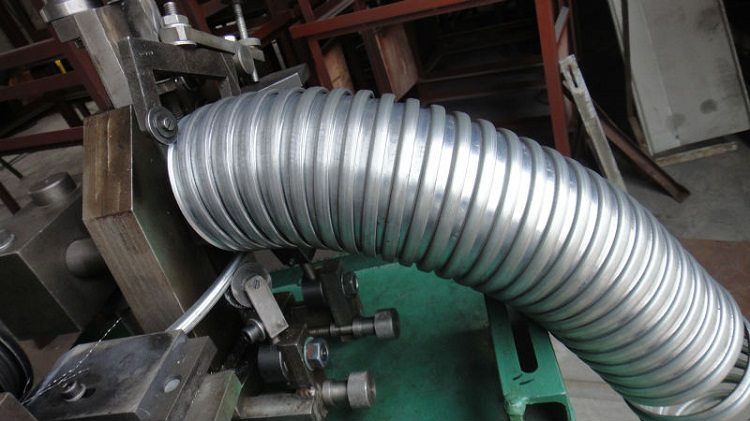

Despite its versatility and high quality indicators, corrugated stainless steel pipes are made using fairly simple technology. The production process involves the following steps:

- pipe forming from special steel tape;

- welding the workpiece with tungsten electrodes. It is carried out using TIG automatic equipment. In the process, the temperature reaches 1150 degrees heat;

- the next step is to check the seam on the laser unit;

- then form a corrugation. For this, special shafts of different diameters are used;

- heat treatment (annealed pipe is characterized by greater flexibility) and packaging. Products are divided into segments of the desired length and rolled into bays (if they are small in diameter);

- to ensure that there are no microcracks in the material and to weed out defective products, each batch is subjected to rigorous inspection. To do this, flexible corrugated stainless steel pipes are placed in a liquid medium under high pressure using special devices. Instruments are attached to each bay. Pressure reaches 10 Atm, and then its fall is traced.

If the product has justified the declared quality standards, it has the following characteristics:

- The norm of the working pressure is 10 Atm., The maximum limit is 60 Atm.

- The nominal temperature during operation of the corrugated stainless steel pipe is within the range of 0 ° C - 100 ° C, the maximum figure is over 150 ° C.

- For individual repair and construction works, pipelines with a diameter of 15, 20, 25 and 32 mm are produced.

Classification of corrugations and fittings to it

Corrugated stainless steel pipe may have different properties, depending on the purpose:

- unannealed. It has elasticity and a little more weight;

- annealed - more flexible. To achieve the desired effect, the products are subjected to heat treatment;

- with a polyethylene sheeting. Such pipes are intended for gas supply, underground utilities or systems that need to be concreted.

To connect together parts of engineering systems, including steel pipelines, brass fittings are used. They come in different diameters, cross-sectional shapes and configurations, depending on the purpose. They consist of a union nut, a body, a retaining ring (plastic or steel), a silicone gasket, which is tightly crimped flexible pipe.

Helpful advice! Do not save on fittings. Get them only from trusted distributors, as a poor-quality product can damage the entire water supply system.

Features and Benefits

The popularity of flexible corrugated steel pipes is due to its high quality and excellent technical characteristics.

The first is durability. Combining flexibility and strength, flexible stainless steel tubing, according to experts, can be used for hundreds of years. They are not subject to cracking, resistant to mechanical damage, and the cross section of the pipe passage does not change even after 50 years.

Secondly, reasonable price. Compared to previously popular copper pipes, corrugated (stainless steel) pipes cost significantly less. This is an ideal value for money. Such an investment will pay off for many years of service. In addition, maintenance and repair of the pipeline will not require large financial investments.

Scale and sediment do not accumulate on the inner walls of stainless steel flexible pipelines, salt deposits do not form, so the pipe does not overgrow. This ensures the smooth functioning of the sewer and water supply. You do not have to further purify the water used for domestic needs.

You can already feel the advantage of stainless steel corrugation upon purchase: compact and lightweight, it is quickly and easily transported.

Installation of stainless communications system does not require much experience and special skills. Pipes can be installed independently. You don’t even need special tools like welding. Therefore, an ordinary and annealed corrugated stainless steel pipe is installed three times faster than its counterparts made of other materials.

Steel corrugated pipes are very flexible, so with their help it is easy to create systems of any complexity

Where to apply

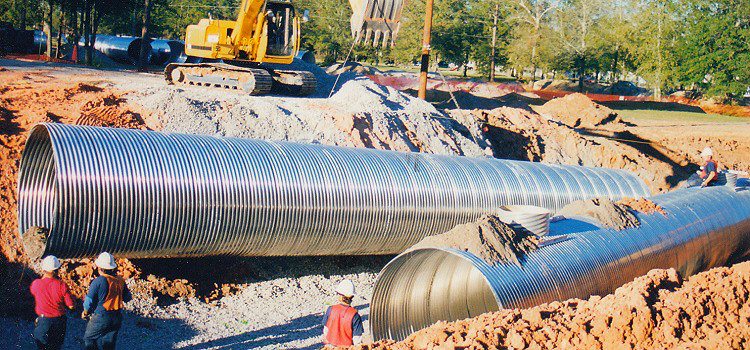

Corrugated communications are universal. They can be used both in centralized and autonomous water supply, heating systems. This is possible due to the ability of the stainless pipe to withstand tremendous pressure with a wall thickness of 0.25-0.3 mm.

Corrugation normally tolerates extreme temperatures, which gives a significant advantage over polypropylene and metal-plastic analogues. When exposed to high temperatures, the communication lines do not deform. And in severe frosts, the stainless steel corrugation pipe is not damaged as a result of compression and expansion of the material. Freezing and thawing do not affect the flexibility of the product (especially if the stainless pipe is annealed), it can withstand strong water hammer quite easily. The material is so flexible that pipes can bend with a radius of 150 to 30 mm. It depends on the diameter of the stainless pipe.

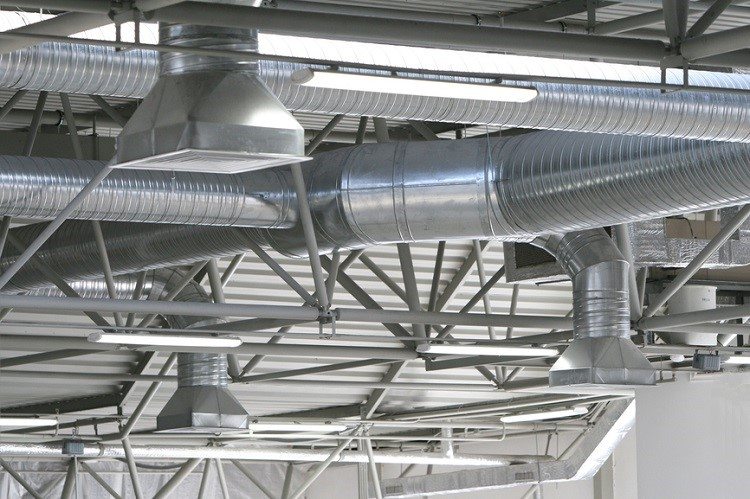

Due to these properties, corrugated pipelines are used almost everywhere. They are used by builders, repairmen, public utilities and electricians. Namely:

- installation of cold and hot water supply systems;

- heating systems;

- insulation of walls and floors;

- piping boilers;

- connection of counters;

- manufacturing heat exchangers;

- gas distribution;

- ventilation and air conditioning systems.

Corrugated stainless steel pipes are also used as a metal hose for electrical wiring and even as an element of a solar collector system.

Corrugated stainless pipes are used not only in everyday life, but also in various industrial systems

Mounting technology

Installing a corrugated stainless steel pipe is quite simple and quick. You can do it yourself without the help of workers. The main thing is to be attentive, accurate and act clearly according to a given algorithm:

- first we connect the fittings to consumers (if we are talking about water supply, then this is plumbing, faucets). Make sure that the union nut on the side where the pipe is connected is not tightened;

- then a sufficient amount of material is cut off. It is better to do this with a roller pipe cutter. Try to keep the cut neat without burrs;

- then the pipe is inserted into the fitting and the union nut is tightened;

- Now lock the stainless steel pipe in position. Use special fasteners (clips or clamps) for this;

- check system health. If water leaks from the pipe connection, tighten the union nuts more tightly.

Note! Although the annealed steel pipe costs relatively little, installation consumes more money than the installation of plastic and polypropylene analogues.

Corrugated pipes are convenient, practical and reliable, so their popularity is growing. Their installation is very simple, but you need to approach it with all responsibility and not save on connecting elements. Substandard fitting will cause the failure of the entire pipeline, and in the case of a heating system or hot water supply, depressurization of the circuit can be dangerous at all.