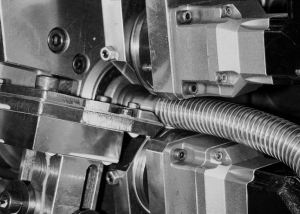

Flexible stainless steel corrugated tubes - For the domestic market, products are new, but quite worthy of attention. A variety of cross-section diameters and exceptional mobility make these products popular in most areas of industrial and domestic use. Options for how it can be applied flexible stainless pipe, there may be a mass: as chimneys, gas pipes, floor heating. Large-diameter corrugations become the basis for the construction of tunnels and pedestrian crossings.

Content

Types of flexible pipes made of stainless steel

In the last century, special attention was paid to the production of corrugated steel products. It is difficult to overestimate their significance: corrugations played a significant role in global structures, such as the Trans-Siberian Railway or the Baikal-Amur Mainline. Stainless steel corrugated pipes can have a completely different cross section - from 8 mm to 15 m. In addition to the usual water and gas corrugations, steel pipes with a non-standard cross section are also produced:

- square (diameter 3-8 m) - used for the device of culverts and tunnels;

- pipe-arches (2-13 m) - tunnels for passage under railways or road forks;

- pear-shaped (1.5-8 m) - stainless steel culvert device;

- vertical ellipse (1.5-6.5 m) - communication tunnels, culverts;

- arched (2-13 m) - pedestrian crossings, small bridges and car tunnels;

- horizontal ellipse (2.6-9 m) - water pipes;

- low profile arches (6-15 m) - railway and automobile tunnels.

Corrugated pipes of circular cross section of large diameters (from 1.5 to 7 m) are mainly used for large-scale culverts. Smaller analogs will be used for private purposes, which will be discussed later.

Installation diagram of an autonomous water supply control unit from a corrugated pipe

Using a stainless steel corrugated pipe, it is possible to carry out a project for a unit of an autonomous water supply system at a site or in a country house. Water supply can be hot or cold. Water will be supplied from a well or a well.

Using corrugated pipes, it is easy to create an autonomous water supply system for a residential building

It is interesting! The main task of the control unit for autonomous water supply is to turn on the pump in automatic mode and turn it off when the water consumption is completed. In the absence of water consumption in winter, the unit drains water to a source (i.e., into a well or well), which prevents freezing in the main pipeline. The system is drained by opening the valve on the assembly and removing the check valve. To turn on the system, the valve is put back on and the valve closes again.

The necessary equipment for organizing a water supply unit is selected depending on the dimensions of the site and the number of devices consuming water. You may need a hydraulic accumulator (capacity is calculated according to consumption), a collector with a certain number of taps, a pump without a check valve.Pump performance also depends on the degree of resource use. To conduct hot water, you will need a storage heater.

To install the control unit from corrugated stainless steel pipes, the following components and tools will be needed:

- Flexible eyeliner (40 cm long) with gaskets and retaining rings.

- Check valve (one inch).

- Two one-inch male thread tees.

- Pressure gauge, pressure switch.

- Five-way fitting.

- One inch crane.

- Two one-inch couplings with a union nut (American).

In addition, a special sealing tape is useful for sealing joints. For mounting to the wall you will have to purchase several clips. Of the tools for assembling this unit, only a few adjustable wrenches are useful.

The connection is carried out in the following order: the first node is connected to the pump, the second to the water heater (if hot water is planned), the third is connected to the accumulator, and the fourth is distributed among consumers of cold water.

Installation of underfloor heating using a flexible stainless pipe

For carrying out the underfloor heating system, flexible pipes of AISI 304 class stainless steel are used. In addition to underfloor heating circuits, such products are used in any water heating systems, when piping (secondary circuit device) boiler rooms and connecting pumps.

A warm floor is laid using annealed thin-walled pipes (wall thickness - 0.3 mm). Due to the corrugated surface of the corrugation, the pipeline compensates for linear compression or expansion, therefore corrugated stainless pipes do not require additives in concrete or cement screed.

The coefficient of thermal expansion for this type of pipe is 0.2 mm per 6 m in length. At the time, pipes made of cross-linked polyethylene, also used for floor heating, have a coefficient of 4 mm by 6 m.

The thermal conductivity of steel pipes is one of the highest and most effective, therefore, the heat transfer of this system will be the greatest. Perhaps, only copper can compete with stainless steel products. But the use of copper pipes will be an unreasonably expensive step towards organizing a home floor heating. The thermal conductivity of steel is 17W / m2which is also quite acceptable.

When using a corrugated stainless steel pipe, concrete is stable heated at a thickness of 10 cm. Heating is neutralized at a concrete layer thickness of 20 cm. The flexibility of the pipes allows the use of the smallest number of fittings, even when designing complex and extensive thermal routes. Fitting also do not need additional tightening after installation is completed.

Important! This circuit of underfloor heating will withstand a constant pressure of 16 atmospheres at an operating temperature of 100 degrees.

Installation of underfloor heating is carried out with the following materials:

- corrugated stainless steel pipe with a nominal diameter of 15 mm (installation is possible only with the help of annealed pipes);

- 1.5 inch brass fittings (1/2);

- cement screed (1 bucket of cement in 4 buckets of sand, plasticizer);

- metal grid.

The flexibility of the corrugated stainless steel allows it to be used in underfloor heating systems both for laying under the screed and for mounting the collector

Laying the first contour of the warm floor is carried out at a distance of 15 cm from the wall. Each next step of the strips of a flexible stainless corrugated pipe will be equal to 20 cm. The temperature of the system along the circuit will be 10-20 degrees higher than the temperature of the internal heating, the so-called "comfort zone". If warm floors perform the function of an additional heating source, it is permissible to increase the step in the middle of the “comfort zone” to 30 cm.

After installation is complete, a pressure test is mandatory with a pressure of 6-8 atmospheres for 3-4 hours.The screed layer dries completely in 20-30 days, depending on the time of year.

Installation of cable channels from corrugated stainless pipe

One of the applications for corrugated pipes is the installation of electrical or communication wiring systems. Cable channels can be laid both inside buildings, along walls and ceilings, and outside (communication networks are meant).

Corrugated stainless steel tubes, acting as insulation for wires, are much superior in quality to plastic cable ducts. They are increasingly preferred, as:

- Stainless steel reliably protects electrical networks from fire, so with their help it is possible to lay the cable, even surrounded by flammable structures.

- Thanks to its excellent flexibility, the corrugated sleeve can follow the contour of walls and floors, which makes installation faster and easier.

- Metal corrugation for wiring provides maximum tightness, protecting wires from moisture and dampness. Steel walls of the sleeve also protect the cable from mechanical damage, including exposure to rodents and other pests.

Wall thickness for corrugated stainless steel metal sleeve is regulated by building codes. Especially these rules are relevant when carrying out repairs with increased fire hazard (for example, in wooden log cabins).

By placing electric cables in a steel corrugation, you can reliably protect the wiring from moisture, rodents and accidental mechanical damage

Requirements for the wire and protective corrugation are presented in table No. 1.

Table 1

| Wire cross section, in mm2 | Minimum wall thickness of corrugated cable channels, mm | |

| Copper wires | Aluminum wires | |

| Less than 2.5 | Less than 4 | Wall thickness is not critical |

| missing | 6 | 2,5 |

| 4 | 10 | 2,8 |

| 6 — 10 | 16 – 25 | 3,2 |

| 16 | 35 – 50 | 3,5 |

| 25 — 35 | 70 | 4,0 |

When bending stainless corrugated pipes, normalized turning angles are observed. Their value will be 90 degrees, 120 or 135. Bending radii are also regulated: a radius of 400 mm is used for systems installed in wall ceilings or for vertical exit. Radii of 800 and 1000 mm are allowed when laying a cable pipeline in monolithic foundations.

Important! If the cable channel intersects with a temperature or sedimentary seam, it is necessary to take into account the location of the compensating devices in the drawing.

Fixing of the electrically conductive sleeve of a stainless steel pipe is carried out at distances not exceeding 2.5 meters for channels with a nominal passage of 15-20 mm and 3.5-4 m for channels with a DN 40-80. Fixing elements will serve as clips or clips. Wiring pipes must not be attached to metal structures or other process pipelines.

If you are installing a hidden laying of wires with insulation in the floor, deepening is done to a depth of at least 20 mm. Mandatory presence of a layer of cement mortar. Flexible cable channels can be laid in wall gates, concrete screed and under decorative panels.

Installing a pipeline of any purpose using stainless corrugations is a rational and economically viable solution. Repair work is carried out with a minimum amount of special equipment: the assembly of standard components from professionals takes no more than 1 hour. However, in some cases, the use of a stainless corrugated pipe is unjustified. For example, smoke channels for boilers made of smooth-walled steel pipes are more safe and efficient.