Modern manufacturers of sanitary equipment produce products that reduce the complexity of laying engineering communications. So, relatively recently in the domestic market appeared stainless steel corrugated pipes. On their basis, it is possible to create gas pipelines, heating systems and water pipes. And the combination of properties such as strength and flexibility makes these products very popular among home craftsmen.

Corrugated stainless steel pipe is a modern material used for the installation of plumbing and heating systems

Content

Features of corrugated pipe

"A ticket to life" stainless corrugated pipe for water supply was given by experts from Japan. Over time, these products have become popular in Europe. Today on sale you can find such products with different diameters, which makes it possible to lay different communication networks.

For connection of corrugated water pipes, stainless steel pipes are used fitting made of brass having a fairly simple design. The features of this type of pipe products include:

- Despite the small wall thickness (0.25-0.3 mm), such pipes are able to withstand significant pressure. This property allows you to install them in both centralized and autonomous systems.

- As raw materials for the manufacture of stainless corrugated tubes, only high-quality steel having the required chemical composition is used. The concentration control of the main components is carried out with high accuracy.

- The ability to bend the pipe with a minimum radius greatly simplifies installation work. The value of this parameter depends on the design features and varies in the range of 30 ≤ R ≤ 150 mm.

- Simplicity of material processing is a very important factor. The product can be cut with ordinary tools like a grinder and metal scissors. But professionals recommend using a special pipe cutter for this purpose.

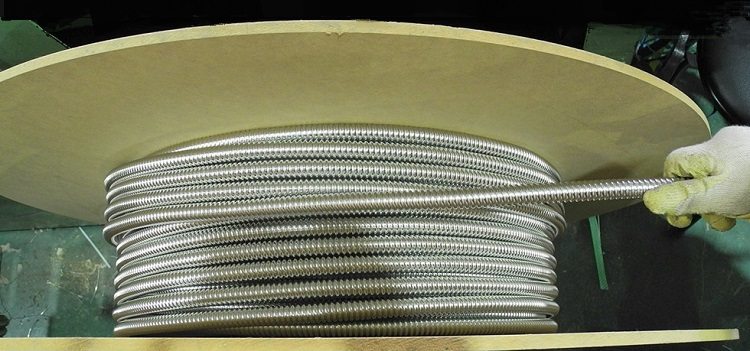

- Due to the fact that the delivery of corrugated water pipes made of stainless steel is carried out in long coils, the number of connections during installation is minimized. This increases the degree of tightness of the system.

Pipes are supplied in long lengths, which reduces the cost of acquiring fittings for connecting system segments

Important! Corrugated stainless steel can withstand very high temperatures. And compared with plastic counterparts, its linear expansion coefficient is much lower, more precisely, it is 12-6(1 / C °).

Production technology

Similar products are manufactured on automated lines. The “human factor” is practically absent, which allows performing basic technological operations with a high degree of accuracy. Products of Japanese manufacturers are considered the most reliable, however, according to the Price / Quality criterion, Latvian goods “breathe in the back”.

Let us consider in more detail the basic stages of the production of stainless corrugated pipe for water supply.

- First, the steel strip undergoes preliminary processing. Then it moves to the molding line.There, the tape bends and turns into a cylindrical workpiece;

- then the main joint is welded automatically in a special environment from inert gases;

- then the smooth-walled workpiece is rolled. For this, parts of various diameters are used. The output is a stainless steel corrugated pipe;

- at the final stage, the material is cut into measuring segments whose length does not exceed 50 meters. For ease of transportation and installation, individual segments are wound into coils.

The pitch of the corrugations of the corrugations and protrusions may differ, as different manufacturers are guided by their Technical Conditions and Standards. However, the quality of the final product does not suffer from this.

Advantages and disadvantages

If we take for comparison similar products made of other materials, we can see that a stainless steel corrugated pipe significantly exceeds almost all of them. The expert distinguishes the following main advantages of these pipes:

- the durability of corrugated stainless steel water pipes is limited only by the life of the o-rings. All other details can be considered eternal;

- the optimal ratio of ductility and stiffness provides resistance to water hammer;

- due to its flexibility, you can turn without the use of special tools;

- not afraid of defrosting;

- can be installed under any cladding, under plaster and even under concrete screed;

The disadvantage of a corrugated stainless steel pipe is only one - the price. Yes, while the cost of this pipe production is quite high. But many homework masters prefer it, because they consider such products to be one of the best.

Installation of pipelines made of stainless corrugation

Most often, corrugated stainless steel pipe is an element of water supply. Often it is also installed for gas supply. Sometimes it serves as an adapter in heating systems.

Important! Acquire fittings for connecting corrugated pipe segments should only be from the list recommended by the corrugated pipe manufacturer. Savings in acquiring such parts of unknown origin can lead to emergencies.

The installation of a corrugated steel pipe is similar to the installation process of products similar in functionality made from another material. But here, product flexibility comes to the rescue. Therefore, the installation of a stainless steel pipe requires much less time.

To mount the pipeline, do the following:

- Separate the required length using a pipe cutter or other available cutting tool. But before this operation, first measure the distance between the connection points taking into account the bend.

- Loosen the union nut directly with a wrench on the fitting. Insert the pipe itself all the way into the inside of the fastener.

- Use the same wrench to tighten the nut until the product is completely locked inside the fitting.

- Bend the pipeline until the desired configuration is achieved, and then fix it on the wall using special fasteners.

- Check for leaks. To do this, submit the working environment to the system. If leaks do not appear, you can begin to operate the pipeline

Installation and operating tips

Like any other technical product, the installation and operation of a corrugated stainless steel pipe should be subject to a number of requirements and recommendations.

- Before installation, check the corrugation for cracks, dents and kinks;

- connection of a stainless steel pipe with a fitting, the material of manufacture of which is subject to corrosion, is not allowed;

- if the water or heating supply pipes are made of ferrous metal, be sure to install a water filter before contacting the brass fitting;

- when mounting a corrugation, do not allow torsional stresses to arise in it;

- When laying a stainless steel pipeline, exclude its contact with corroded ferrous metal;

- To securely fix the pipe, you can use plastic fasteners. To give greater aesthetics to the engineering communications being created, it is recommended that it be fixed using non-ferrous metal fasteners. And, of course, for this fittings directly made of stainless steel;

- For underfloor heating use only solid pipe sections. No additional connections below floor level;

- do not allow electric current to affect the stainless steel corrugated pipe;

- do not exceed the number of flexions / extensions indicated in the product passport. In general, it is advisable to minimize them.

Interstate Standards

Requirements for corrugated products for water supply, gas pipelines and other communication networks are indicated in clauses GOST 10705-80, containing information on electric-welded steel elements.

To determine the quality of products, several samples are taken from a batch of manufactured products, which are then subjected to a series of tests.

Important! Joint quality control without fail involves additional testing with hydraulic pressure.

As for the impact test, only three patterns are taken. In the case when it comes to the chemical composition of raw materials - steel - then it is, first of all, determined by the standards of GOST 22536.0.

The manufacture of annealed stainless steel corrugated tubes is carried out in accordance with other standards. Manufacturers should be guided by the points of GOST 9941-81, which mention information about heat-deformed seamless products.

The main regulatory document in this area, adopted by the International Organization for Standardization, is ISO 10806, dated 2003.

Leading manufacturers

The highest quality products are manufactured by several companies.

A long service life of a stainless corrugated water supply system is possible only when using high-quality materials for its installation

Company KOFULSO. South Korean company KOFULSO LTD is a recognized world leader in the production of stainless corrugated pipes and brass fittings. In the domestic market, her products have been sold for more than 3 years.

Brand GOFRA-FLEX. This is another manufacturer from South Korea. Its products are certified in the EU, USA, Russia, Ukraine and other countries.

Trademark NEPTUN IWS. The products of this Russian brand are widely used in domestic and industrial construction. Subject to the operating conditions specified in the passport, products of the Neptun IWS trademark will last an unlimited period of time

As practice shows, installing a pipeline from a stainless steel corrugated pipe takes up to 3 times less time than installing heating and water systems from other materials. Therefore, interested parties should consider using corrugated stainless steel pipes for arranging various utilities.