Installation of drinking pipelines is a very important event, which must be approached with all seriousness. Water that is transported through such communication should not change its chemical composition. It follows that the pipes for such communication should not be oxidized. Among metal pipes, stainless steel products are the best quality option.

Corrosion-proof eyeliner is one of the most practical and durable options for connecting to a water supply system

Content

Stainless steel plumbing

For the installation of drinking communications, two types of stainless pipes are used:

- galvanized stainless steel;

- from chromium-containing stainless steel.

Both of these types have proven themselves in work. They are the most environmentally friendly among all and practically do not affect the chemical composition of water. Galvanized steel is an alloy that contains iron and carbon, and the chromium-containing stainless steel contains chromium, as its name tells us. In air, a chrome-containing stainless steel water pipe is covered with an oxide film, which performs protective functions.

Hygiene studies have shown that both of the above types are harmless to human health. In addition, they have incredible resistance to aggressive corrosion and high temperature performance. Stainless steel pipe for water supply has excellent strength characteristics. However, they also have their drawbacks, which are worth paying attention to.

After 8–10 years, such a pipeline begins to accumulate salt deposits on its inner walls, which leads to a narrowing of the pipe lumen and a decrease in communication capacity. It is worth noting that this minus applies to cold water pipes.

Such pipes are produced, as a rule, in two ways:

- welded;

- seamless.

Helpful information! The welded method of manufacturing is simple and budgetary, however, seamless pipes have increased strength characteristics.

Corrosion-proof pipes are perhaps the most reliable in operational terms, this is due to their popularity in the modern market. In addition to conventional stainless pipes, there are products that are also used for drinking water pipes - stainless flexible corrugated pipes.

Scopes and advantages of a flexible corrugated stainless steel pipe

Corrugated stainless water pipe was invented at the end of the last century. It has high performance characteristics and is used both in everyday life and in various industries. Consider the main areas of application of such a product:

- drinking pipelines;

- technical water supply;

- constructions of a water heat-insulated floor;

- gas distribution systems;

- fire extinguishing systems.

Stainless steel corrugated pipe has a number of positive qualities:

- compactness, which allows you to quickly and quickly perform installation and save space when connecting various equipment to water pipes. In addition, they store and transport these pipes rolled into coils, which is very convenient;

- flexibility. This property allows the quick installation of such products, even in hard-to-reach conditions. Such pipes bend at any angle;

- installation by means of a nut connection, which does not require welding equipment and special knowledge in the field of construction;

- presentable appearance;

- resistance to freezing temperatures;

- resistance to water hammer in the system;

- resistance to minor mechanical influences;

- resistance to vibrations in the system;

- abrasion resistance;

- in addition, a flexible stainless pipe for water supply is resistant to ultraviolet rays;

- unlimited service life of communication from such pipes allows you to save on their replacement and repair work. It is also worth noting that the fitting connections in such systems have an operational life of at least 30 years.

Flexible steel pipes are not afraid of high temperatures, this allows you to use them to connect water heaters

The main disadvantage of such products is the rather high cost, which is due to the technical characteristics, as well as the cost of the materials of manufacture. Steel in itself is quite an expensive material.

Key Features of Corrugated Stainless Pipe

As mentioned above, flexible corrugated pipes are resistant to corrosion, in addition, they have many unique characteristics. The pressure that such a pipe can withstand is 60 bar, which is almost 4 times higher than that of a conventional steel pipe. The pressure indicator for household drinking water systems is usually 7 bar.

Important! When purchasing such pipes, it is necessary to be careful and carefully check that there are no damages or defects on their surface.

The maximum temperature at which a corrugated stainless product can be used is 110 ° C, and it is not afraid of negative temperatures. Resistance to low temperature indicators is due to the design features of stainless corrugated pipe. Corrugation compensates for water expansion at low temperatures.

Installation of such communication is simple and thanks to flexible pipes it is possible to carry out designs with any configuration. The fitting system allows installation without special tools. In addition, for such a pipeline a smaller number of connecting elements is required than for a conventional one (from simple metal pipes).

Stainless pipe joint

Corrugated stainless steel pipes for water are installed by connecting individual parts of the pipeline with special fittings. In addition to the fitting system, the joining of individual elements of a flexible stainless water supply can be performed by other methods: crimping, welding and flange connections.

Welding a pipeline requires special welding equipment, as well as knowledge and skills in this area. Welding stainless pipes can be performed in an inert gas environment. This method requires the use of special tungsten electrodes. However, the so-called plasma welding is considered the most common method. In this case, the work is performed due to the directional plasma arc. Not every owner is able to independently carry out this process without errors, so consider other popular methods that do not require special skills.

Flanged pipe docking is typically used in systems that require periodic routine inspections and repairs. This connection allows you to quickly replace individual elements of communication. Flange connection is without threading.

Flange connections have their drawbacks:

- high metal consumption;

- deterioration of sealing performance at temperature extremes and water hammer.

Threaded joints of stainless flexible corrugated tubes are made using fittings. The most popular type of fitting is considered to be a coupling, through which two pipes are connected in a straight section of the pipeline. The fitting method of installation is the most popular because of its simplicity and high speed.

However, you need to carefully consider the selection and installation of fittings. Such parts are detachable and in the event of a breakdown, the failed part can easily be replaced with a new one. The connection of stainless steel water pipes to plumbing equipment is carried out using a special product - stainless steel liner.

Flexible stainless steel braided water hose

Previously, bulky structures were used to connect plumbing and other equipment, which were fastened together by clamps. This method was notable for the complexity of installation, as well as low reliability and, in addition, an unpresentable appearance. Today there is a simpler and more reliable way to bring water to the toilet, boiler, washing machine or dishwasher. This way is to connect using a flexible stainless steel eyeliner. Such devices are very popular and are used everywhere.

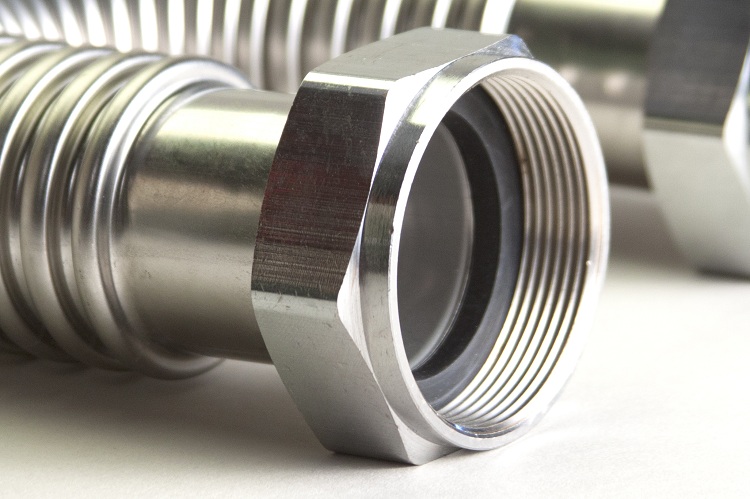

Flexible water inlet is a hose that can have different lengths (from 30 cm to 5 m). Both ends of such a hose are equipped with special nozzles or nuts with rubber gaskets, as well as gaskets. Thanks to rubber seals, the required sealing performance is achieved.

As a rule, water inlets are made of stainless steel (flexible corrugated water inlet for stainless steel) or have a braid of this material. This is due to the fact that stainless steel is superior to other materials and has excellent anti-corrosion properties that are necessary when in contact with water.

Helpful information! The purpose of such a hose is determined quite simply: the product for cold water has a blue thread in its braid, and the model that is used to connect hot water — red. Combined products differ in that they have both colors in their braid.

Stainless steel hoses are used not only for household purposes. They are in demand in other areas:

- building;

- Agriculture;

- mining industry.

Flexible stainless steel water inlet is designed to operate in harsh conditions and is resistant to aggressive chemical compounds. Consider the basic requirements that such hoses must meet:

- flexible eyeliner must have good leak tightness, which is feasible with proper installation;

- the gasket material must be very high quality and wear resistant;

- the nut must have a thread without marriage;

- a special rubber seal must be present.

Selection of optimal sizes of flexible eyeliner

When choosing an eyeliner for a particular case, the following characteristics must be considered:

- hose diameter. The cross-sectional indicators of a flexible eyeliner for water are determined taking into account the flow rate of one or another plumbing equipment.To connect the toilet, as a rule, use a hose with a cross section of 8 mm, for a sink - 10 mm, and for a bathtub 15 mm;

- hose length. The length is determined depending on the specific case. The connected product should not be too tight or, on the contrary, should not sag much, thereby forming an excess.

In case of improper installation of such a hose, its performance is reduced. In addition, it is worth considering the material from which the hose is made. The life of the flexible eyeliner differs depending on the material of manufacture.