A prerequisite for the successful installation of a heating system based on a corrugated stainless pipe is the tightness of the joints. Dangerous and critically unacceptable leaks in fluid and chemical systems. Creating a strong and reliable pipe connection provide fittings of various types. Special tools and knowledge of the basics of connecting corrugated stainless steel pipes are the basis of the reliability and durability of the completed project.

Content

What are fittings?

Mounting elements, without which it is extremely difficult for both a professional corrugated pipe installer and a novice foreman, are fittings. That is what the elements of the connecting fittings that perform various functions were called, for example:

- implementation of a tight transition between two branches of the pipeline;

- creating a strong connection of pipes of various diameters;

- adjustment, stopping or changing the direction of flow of the working fluid in the system;

- increasing the length of the circuit without stopping the entire system, convenient in case of working with stainless pipes;

- changing the geometry of the gasket and upgrading the existing system;

- replacement of part of an outdated system. Laying a new heating or water circuit with corrugated steel pipes.

In addition, the fitting for corrugated stainless pipes is responsible for creating branches from any circuit in the system.

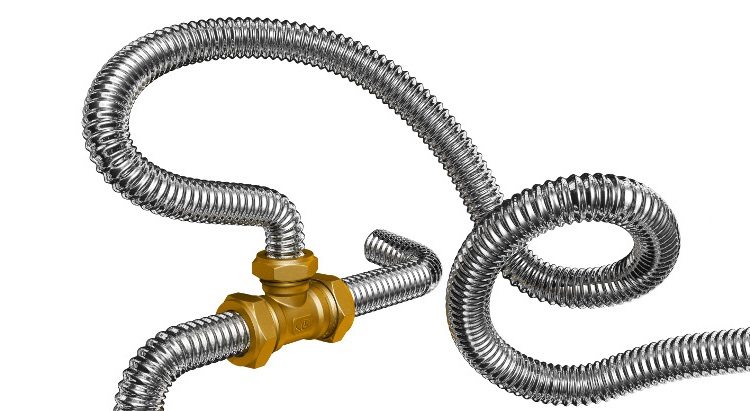

Corrugated pipes are used to solve various problems, but their connection without special fittings is impossible

With all the variety, conditionally fittings are divided into two categories:

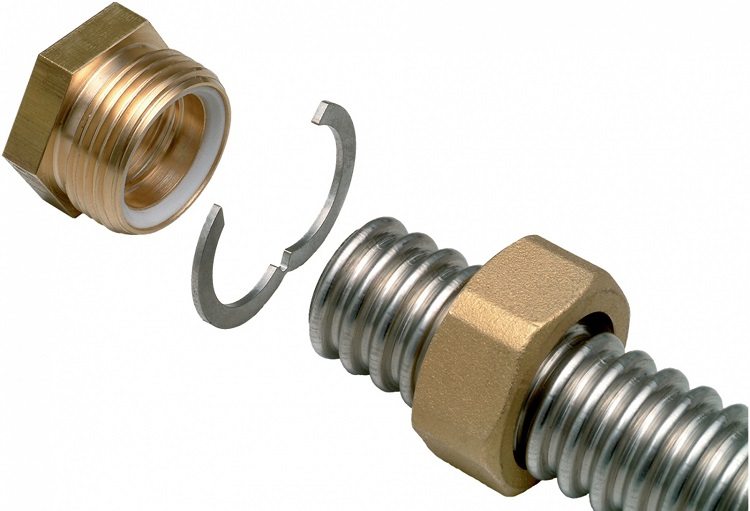

- Seamless elements. They are a one-piece fitting, characterized by extremely high reliability, but during installation, specialized tools, for example, crimping pliers, may be required.

- Electric welded part. An armature of this type consists of several elements precisely fitted to each other to ensure a minimum clearance.

The installation principle is understandable and simple enough, and the variety of fittings for stainless corrugated pipes is an excellent solution for assembling the system yourself. Subject to all technological steps, a strong and durable connection is formed.

As a rule, manufacturers of stainless corrugated pipes are not eager to arrange the production of fittings for their products. Economic calculations have shown that for large enterprises this is not a priority. The growing market demand for corrugated steel pipes provides the manufacturer with a stable profit.

Fittings are produced in various countries. Well-proven components from European manufacturers. Domestic manufacturers are increasing production volumes while tightening quality control of their products.

Important! Before starting the installation of the system, it is recommended to lay out the fittings according to the plan - project, and carefully check for chips and mechanical damage. A missing or unevenly installed seal is fraught with leakage and malfunction of the entire circuit.

Different elements are used for gas supply and water supply systems, it is worth paying special attention to this when drawing up a project.

Types of fittings for corrugated pipes

Depending on the task assigned to the installers and the overall project estimate, taking into account the installation conditions and the diameter of the pipes, the most suitable type of fittings for the stainless corrugated pipe is selected: brass, plastic or steel fittings.

Steel components

The most common, easy to install and most promising type of fittings are metal fittings. They are made of stainless steel, and the chromium content in the alloy can reach 16-20%.

Most often, fasteners for metal pipes are also made of metal, for example fittings for corrugated pipes made of stainless steel or brass.

Benefits:

- Do not oxidize when exposed to moisture. Internal surfaces remain clean, no signs of corrosion even after prolonged use;

- stainless steel fittings are resistant to mechanical stress;

- stainless steel components are used in a wide temperature range and are not affected by freezing temperatures;

- resistant to water hammer.

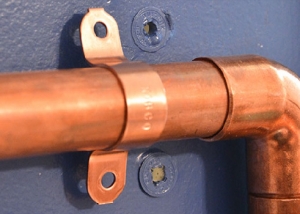

Brass fittings are used as transition elements for connecting stainless corrugated pipes to pipes made of other materials - polymer or combined type.

The threaded fitting connects the pipes securely, but the thread will need to be tightened with a wrench

Brass fittings are installed using crimp rings or threaded connections. For high-quality installation use crimping pliers or a set of lingering wrenches corresponding to pipe diameters.

Reliability of crimp fittings is not inferior to steel components. The most widely used brass and copper connecting components from well-known manufacturers of heating equipment.

The use of cheap, low-quality brass components is a sure way to achieve the shortest possible time of trouble-free operation of the system. Pipes will regularly perform their function up to the area with an improperly selected fitting, then the fluid will leak.

Plastic fittings

They are used as connectors in combined systems or for connecting to a centralized water supply system. With their help, it is easy to join polypropylene and steel stainless corrugated pipes.

Important! A common parameter for any type of fittings are: corrosion resistance, and insensitivity to a sharp pressure drop in the system. Correctly selected type of fittings will make it easy to implement the installation of a system of any complexity.

When installing plastic fittings, you should not use a lot of force to tighten the nut, it can simply burst.

The main types of fittings for stainless steel pipes

Coupling. The most common type, designed for direct connection of pipes in straight sections.

Turning angle. Used to modify the geometric components of a piping system. Though flexible corrugated pipes easily take the desired shape, it is not recommended to bend them with a radius less than two pipe diameters.

Tap tee. Allows you to redirect part of the flow from the central highway.

Spider. It is used to branch the central flow of the working fluid in several directions.

Technological stub. Allows you to completely block the working circuit or part of the system according to the project, or for the period of restoration and repair work.

Adapter connector. With its help, pipes of different diameters are spliced, this is the most practical and convenient type of connecting fittings.

Tools and equipment for installation

A prerequisite for installation is the availability of special tools for trimming pipes and fixing fittings. The minimum set of installation engineer for steel corrugated pipes includes:

- scissors - a pipe cutter, only with their help it is possible to cut a corrugated pipe from a stainless steel, preserving its shape and providing an accurate, even cut;

- tool for fitting fittings;

- long wrenches or crimping tools;

- device for flaring the ends of corrugated products.

The professional master in the arsenal has a rarely demanded, but indispensable unit: a device for creating welded joints, if it is not intended to use a crimp fitting for stainless pipes.

When arranging a “warm floor” system based on steel corrugated pipes, an inexperienced master can make a mistake: use fittings for a stainless pipe in the form of a coupling connection of a circuit laid on the floor plane. This is prohibited by the installation rules, and can lead to unpleasant consequences in the form of leaks and loss of tightness already at the stage of commissioning.

Installation, repair and maintenance of plumbing and heating systems must be done by a qualified craftsman. For gas systems based on corrugated stainless steel pipes, the presence of a professional installation engineer is a prerequisite.