Fixing bracket - a part used to attach any element or part of the structure to a horizontal or vertical surface. It is a strip curved in a certain way (in the form of the letter "P" or an arc), most often, metal. Reliability of accession is achieved due to a sufficiently large area covered by the bracket, compared with other types of fasteners.

Content

Where is the metal bracket used

If you need to attach some structure to a concrete, brick or wooden surface, then the best choice among the parts that ensure the reliability of the installation is a two-arm metal bracket. In this case, it does not matter what the surface will be to which the structure should be attached:

- vertical

- horizontal

- inclined.

Metal staples are predominantly made of steel, which is protected by a hot dip galvanizing procedure for corrosion protection. The galvanized product will last much longer and provide the design with greater aesthetic appeal.

Based on the number of sides adjacent to the surface, the details are classified as follows:

- Single-foot metal bracket (single-sided).

- Two-arm metal bracket (double-sided).

The widest use of reliable metal fastening devices has led to the appearance of a large number of its varieties, depending on the scope. They are used:

- in construction - for fastening wooden structures;

- during rigging. In static and lifting systems, they play the role of temporary bundles, which attach rigging devices;

- for packing. When transporting goods secured by packing tape, it itself is attached with brackets;

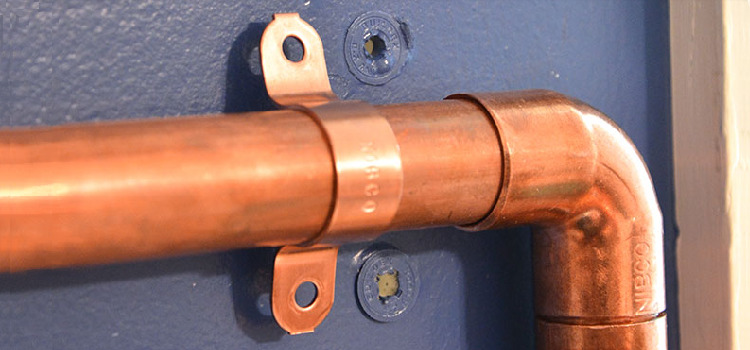

- when laying pipes, cables, corrugated metal hoses;

- for attaching to furniture;

- at home.

Selection of parts for fastening pipes

When choosing elements that allow for reliable installation of the pipe, the following are taken into account:

- the nature of the surface, vertical, horizontal or inclined;

- the purpose of the mounting device;

- sizes

- pipe section.

Depending on the outer diameter, a part is selected for fixing it. A two-arm bracket for fastening pipes is used in cases where their diameter does not exceed a few millimeters. It is fixed with screws or screws.

Note! Usually, a metal two-arm bracket is used when engineering communications are laid outside the premises.

One-foot (one-sided) part is used when it comes to dealing with pipelines with a diameter of 10-32 mm. The choice in favor of a one-sided product is also determined by a large number of bends and bends of pipes, the need to lay electric cables or telecommunication. It provides reliable fixation of the pipe to the surface due to the presence of stiffeners in the arched bend.This structural element determined the use of one-sided fasteners as providing increased reliability of the installed structure.

The design will be fixed securely only if the size of the brackets exactly matches the diameter of the pipes

Brackets for mounting metal hoses

To attach the metal hose, it is placed in the bend of the fastener and pressed to the surface in the right place. It is very convenient to attach using a single-sided part or clip, since if necessary, you can quickly bend the loose end, and then return it to its previous position. A metal two-arm staple used for a metal hose will naturally provide greater reliability. But it will be possible to remove the corrugated metal hose only by unscrewing the screws (self-tapping screws).

Using staples for a metal hose is extremely convenient. They are available in different diameters - from six to forty millimeters. For their installation, both mechanical and automatic tools can be used.

Note! The required thickness of the part is determined taking into account the load attributable to the installed structure.

Using a construction stapler or other automatic (or mechanical) tool greatly facilitates the work. The construction stapler should simply be pressed tightly with the hole to the desired location, then lower its lever with a short clear motion. As usual, the instructions for the tool provide guidance on the uniformity of installation of parts.

Benefits of Use and Acquisition Guidelines

Reliable and cumbersome details still have a number of advantages that explain their wide distribution:

- duration of operation;

- excellent resistance to mechanical stress;

- universality of application;

- low cost.

Important! When purchasing fasteners, you should pay attention to their color. Galvanized metal products should have a light silver shade.

Another circumstance regarding the acquisition of metal staples relates to the fulfillment of EU requirements, according to which the coating layer is free from hexavalent chromium. This not only made the products safe for human health (which was the reason for the appearance of the requirement), but also affected their strength for the better.

Choosing the right products, it is important not to make mistakes. Therefore, it will be quite out of place to look at the nomenclature on Internet sites and expand your ideas about the variety and specificity of the use of products. After looking at the photos, it will be possible to consolidate the visual representation of the desired product. You can also take the help of a trained consultant, paying particular attention to the nature of the surface and the material of the structure.

Galvanized metal brackets for fastening with the correct selection and installation will provide exceptional reliability and attractive appearance.