The ball valve belongs to the class of manual locking devices. He found application in heating, plumbing, gas systems and in the oil industry. The reliability and convenience of the design of such parts led to the fact that they perfectly replace wedge gate valves, as well as conical and cylindrical cranes. Their main purpose is to provide the ability to control or completely block the movement of liquid or gaseous media.

Content

Design and Application

Ball is called a valve (tap), the shutter of which has a spherical surface. Its design includes the following elements:

- body. It can be solid (made by welding) or collapsible. Valves of the first type cannot be repaired. Collapsible devices are repairable. But in comparison with all-welded ball valves for water, they have more weight, more complex construction and greater cost;

- ball. This element is produced in two versions - floating and fixed. Its passage opening may have a cross section smaller or equal to the nominal diameter of the valve;

- movable spindle. With its help, the locking part is rotated;

- removable handle;

- end ftoroplast rings. They provide a seal between the body and the polished ball. Fluoropolymer rings are characterized by an order of magnitude less abrasion than rubber seals. Thanks to such a device, valves for water leakage of liquid are practically eliminated.

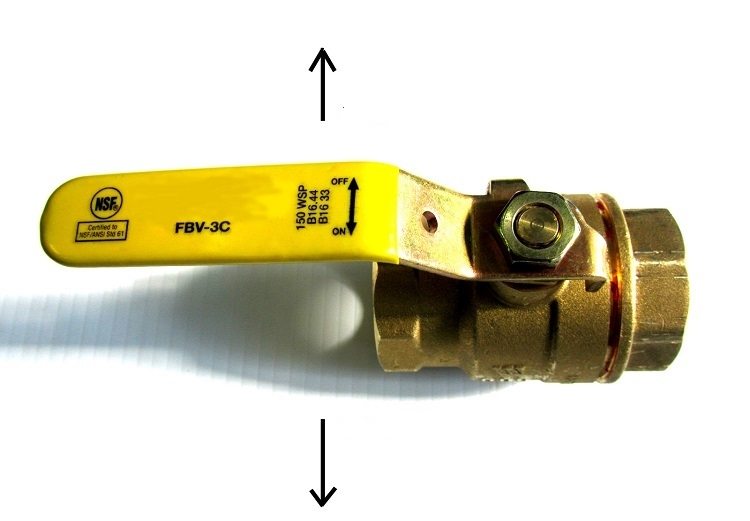

Inside the valve there is a metal ball, which is responsible for regulating and blocking the flow of water

In the steel ball valve located in the valve body, there is a hole whose axis is oriented parallel to the direction of flow. Rigid fastening of the rod and ball forms the axis of rotation, which is perpendicular to the direction of water movement. If the axes of the hole in the ball coincide with the fluid flow, the valve opens. If you turn the valve stem 90 degrees, the direction of the axes becomes perpendicular to each other. As a result of this action, the thread will shut down.

The scope and main characteristics of the ball water valve are regulated by GOST 9702 87. This device is used in systems for transporting liquids at an industrial and domestic level. Such devices are installed on any - plastic, steel, copper and other pipes.

Important! It can be used as shut-off and control valves in systems whose diameter varies in the range of 10 ≤ D ≤ 13 millimeters at a working pressure not exceeding 2500 kg / cm².

High tightness and minimal hydraulic losses recorded with the crane fully open, allow the use of ball valves for transporting steam, as well as gases in the liquid state of aggregation. Among the most effective modifications of such devices working with a gas medium, experts single out equal-flow cranes of imported or domestic production with a nominal diameter of up to 50 millimeters equipped with an emergency shutdown machine.

Types, their advantages and disadvantages

The classification of valves for water is carried out according to several criteria, the main of which is the design.

Valves come in many different shapes, which allows them to be installed in different parts of the plumbing system.

On its basis, these details are divided into:

- direct-flow;

- walk-through;

- mixing;

- angular.

The scope of application of mixing taps is mixing liquids, for example, two streams of water of different temperatures. Modern industry also admits special types of valves designed for operation in non-standard conditions. These can be very high temperatures or atypical work environments.

If we take into account the functions performed, then such details are:

- locking;

- locking and regulatory;

- special purpose.

For example, the device of a water valve - an American allows you to successfully use it as a traditional drive with direct and reverse thread, the design of which includes a coupling with a lock nut.

By capacity, ball (valves are divided into full bore, partial bore and standard. The value of this parameter is calculated by the formula:

TA = So /Dt . where

TA - throughput, So - section of the hole in the ball of the valve, Dt - pipe diameter.

For a standard device, TA is 0.7-0.8, for a non-bore - 0.4 ... 0.5, for a full-bore TA, it ranges from 0.9 to 1.0. The installation of a part-way valve for water is carried out in pipelines with a small flow of the working medium. Such parts are made of steel, cast iron, bronze, brass, polyethylene and even titanium.

The advantages of a water ball valve include:

- reliability and durability;

- compact design;

- ease of management;

- minimal water loss;

- lack of stagnant zones and twists;

- high tightness;

- minimal wear with active depreciation.

There are very few drawbacks. One of them is that if the mechanism fails, it will not be possible to repair it.

Manufacturers do not recommend using ball valves to regulate the flow of water, but only to completely open or close the passage.

Important! Failure to do so will cause a quick depressurization of the device.

Device features

Ball valves open and close by turning the handle left and right. In a mixing type device, this can be done up and down. Such designs do not contain many moving rotary parts, which provides a minimum risk of leakage.

In industrial production, flanged ball valves are successfully used. They are so reliable that they can be installed on critical equipment, for example, in the oil industry. A clutch water ball valve is used in the heating system of the housing and communal services for transporting hot water. But with one caveat: in the coolant, the presence of abrasive particles is unacceptable.

The simplest design is characteristic of household ball valves for cold water. The diameter of the hole in the ball of the full bore device should be approximately equal to the cross section of the pipe. Heating systems need to use a special device to remove air from them. For this purpose, the so-called Maevsky cranes equipped with a valve are installed. The handle that rotates the ball device in them is double (butterfly stroke) or has the form of a single lever.

You can also find water ball valves on the market, with which you can install household appliances such as dishwashers. Their tap is equipped with a filter.This technical solution prevents the ingress of abrasive particles into expensive imported equipment designed for water with a high degree of purification.

You can not ignore the modern Finnish water faucets. Their ball mechanism provides for the adjustment of the pressure force and water temperature in one simple movement. Convenience is achieved through a more complex internal device. Although they cost more, many of our compatriots prefer them.

Valve mounting

Proper installation of the ball valve will ensure safe operation and extend its life. The installation process is no different from installing a threaded fitting. However, there are some nuances. Experienced home masters recommend:

- choose a convenient place for the crane. Nothing should interfere with the rotation of the lever-handle;

- when replacing, removing the old tap, clean the thread from flax and try to wind a new one. It is often found that 2-3 turns simply rot. If this happens, cut the thread;

- Before you wind the flax, you need to make sure that the crane is screwed without it 4-5 turns. Proceed with mounting the valve only if this condition is met;

- installation must be carried out taking into account the direction of the water flow. It is indicated on the case of this part.

Important! To prevent leaks, it is necessary to ensure that the valve is wound up by at least 4 turns.

In conclusion, it should be noted that in the modern market a wide range of water ball valves is presented. Therefore, to choose a device that allows you to optimally solve the problem, will not be any difficulty.