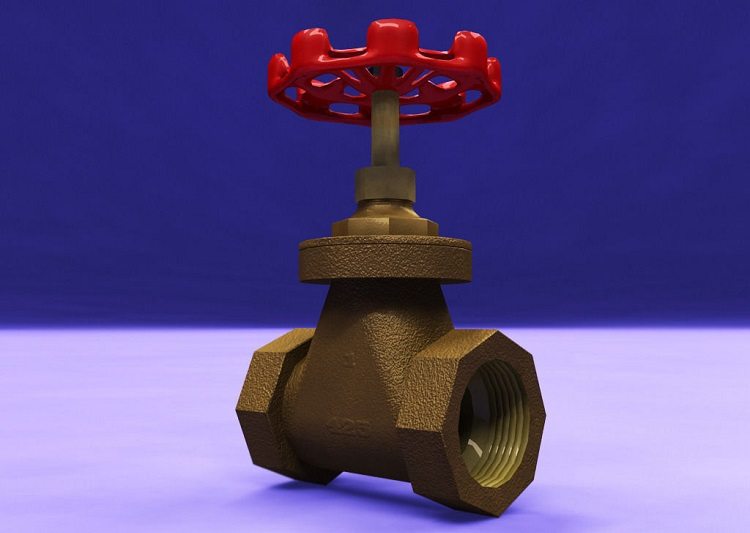

The control valve is one of the types of shutoff valves and is a special device that is mounted on the spindle. Its main function is to shut off the flow of liquid or other working fluids, for example, water (cold, hot), steam, etc. It is recommended that shut-off and control valves be installed in the case of conditional pipe diameters (steel, plastic, etc.) from 25 to 35 cm and pressure not more than 2.5 thousand kg / cm2. Overlapping is only possible in the horizontal plane.

Content

Varieties of control valves

These types of control valves are distinguished:

- standard (valves);

- pressure reducers;

- reverse view;

- bypass type;

- recharge.

By design features, the control valve is single-seat and two-seat. In the first version, the calculated cross-section of the passage of shut-off and control valves is formed by one shutter, in the second - two. The shutters of the two-seat valves are located on a single axis and operate in parallel.

Depending on the type of flow shutoff, shut-off and control valves and control-through valves can be distinguished. The latter are usually located in straight sections of the pipeline.

Design features of the case are quite diverse. In this regard, there is a division of valves into checkpoints, straight-through, mixing, angular.

Note! An angle control valve is usually mounted on the corners of the pipeline, since its nozzles are perpendicular.

The design of control valves is very different and they are classified depending on the purpose of the type of flow shutoff

In direct-flow valves, the nozzles are located opposite one another. The design of the mixing type provides for a different number of nozzles, so that it is possible to connect streams having different parameters.

Characteristics of shut-off valves

The shut-off valve is a device in which the flow control is carried out by means of a reciprocating movement along the main axis of the shutoff rod.

This type of assembly allows you to increase or decrease the power of the fluid flow, as well as hermetically close the shutter. In the shut-off and control valve, a spindle is used as a movable mechanism. It is screwed into the nut thread, which is located on the body.

Shut-off and control valves are characterized by such advantages:

- creating fine adjustment;

- maximum simplicity, reliability and maintainability;

- minimum dimensions;

- any spatial position during installation.

The presence of a thread makes it possible to obtain and fix any intermediate position of the locking mechanism. In addition, the impossibility of his spontaneous change of position at high pressure values is guaranteed.

One of the disadvantages of such valves is that they can only be used to regulate the flow in the line transporting uncontaminated liquid

Among the minuses of shut-off and control valves, one can distinguish overstated hydraulic resistance, the inability to use in pipelines transporting contaminated liquid and restricting flow in only one direction.

Features of thermostatic valve

Thermostatic valves control the flow of refrigerant that enters the evaporator of the refrigeration unit. At its output, almost constant overheating is supported.

Note! In this case, overheating is the difference in temperature of the refrigerant vapor at the outlet of the evaporator and boiling.

The design of the thermostatic valve includes a thermocouple, which includes a diaphragm, a capillary tube and a thermowell. The valve seat closes or opens, depending on the pressure transmitted by the diaphragm (using one or two pushers). Below the locking element is a spring that controls overheating.

The diaphragm is driven by one of the types of pressure:

- thermal bulb;

- equalizing;

- springs.

When the valve works well, the pressure of the bulb is equal to the sum of the pressures of the spring and equalizing. The thermal bulb performs the function of sensing the temperature of the refrigerant vapor at the outlet of the evaporator.

Distinguish thermostatic valves with internal and external types of equalization. The scope of the first type is limited - only in a one-way evaporator with a pressure drop equivalent to a temperature change of ° F. The second type of valves is used in any systems.

Control Valve

Regulating check valves operate by changing the cross section. Their design is quite complex, and the weight and size are large. Often such mechanisms are equipped with an electric drive. Control valves through passage are fastened with flanges or threads.

The advantages of such products include:

- the possibility of use at high pressures and ambient temperatures inside the pipeline;

- the possibility of using steam, water, hot oil, liquefied gas, compressed air, and chemical liquids during transportation.

However, it is important to consider that the flow control valve has significant hydraulic resistance, there is a stagnation zone and repair work can only be performed by specialists because of the structural complexity of the element.

Each valve contains manufacturer's instructions with installation instructions. To maintain effective valve operation, it is recommended:

- additional installation of the mesh filter;

- manometers (before and after the valve);

- Do not subject the product body to compression, bending, torsion, or other external loads;

- Do not use control valves for other fluids if it is intended for water supply.

Before installation, it is important to carefully study the technical parameters and operating conditions of the product. Then long-term and high-quality operation of the mechanism will be guaranteed.