A ball valve manufactured in accordance with GOST 9702-87, 28343-89, 28908 - 91, 21345-2005 is a type of shut-off and control valves with a shutter (stopper) in the form of a sphere (ball) through which a working fluid passes through a round hole. Invented more than a century ago, ball valves gained popularity with the advent of synthesized rubber and fluoroplastic, the use of which ensured the density of the overlap of the circulation of the working medium.

Content

Classification of Ball Valves

According to the diameter of the hole in the shutter (movable element) to the inner diameter of the pipe on which the device is installed, locking devices are referred to:

Full bore. For a full bore ball valve mounted on a pipe, the diameter of the hole in the ball valve coincides with the internal diameter of the pipeline. High reliability of full bore ball valves manifests itself in the level of circulating fluid losses when open. It is negligible and almost equal to the losses during the passage of fluid through the pipe, the length of which is equal to the length of the body of the full bore ball valve. This level of hydraulic losses is several times lower than other types of valves. This circumstance contributed to the fact that a full bore ball valve is in demand as the main locking device on the linear part of powerful trunk pipelines.

Reduced or standard bore. In a reduced ball valve mounted on a pipe, the diameter of the hole in the ball valve is inferior to its inner diameter. The difference is selected in one standard size. Standard bore (reduced) locking devices are used in pipeline systems for which partial pressure loss when the valve is open does not become critical.

By the type of connection, the device is referred to:

- Flanged. Flanged locking devices are installed where welding is prohibited. They are also used in pipelines, which provide for the possibility of partial disassembly and subsequent assembly.

- For welding. Weld-mounted ball valves are installed to achieve special joint strength and to ensure complete tightness of the shutoff of the circulating fluid flow. Such a connection is usually used in a hard-to-reach and / or especially critical section of the pipeline.

- Muftovym. Coupling ball valves GOST 28908 - 91 are equipped with internal conical or cylindrical threads. The main area of their application is utilities.

- Combined. Locking devices with combined connection do not have a clearly defined main scope. They are installed in areas of various pipeline systems.

Among special-purpose devices are:

- Three way. With their help, redistribute the flows of the working environment.

- Equipped with heated housing.

- With leakage control.

Design features

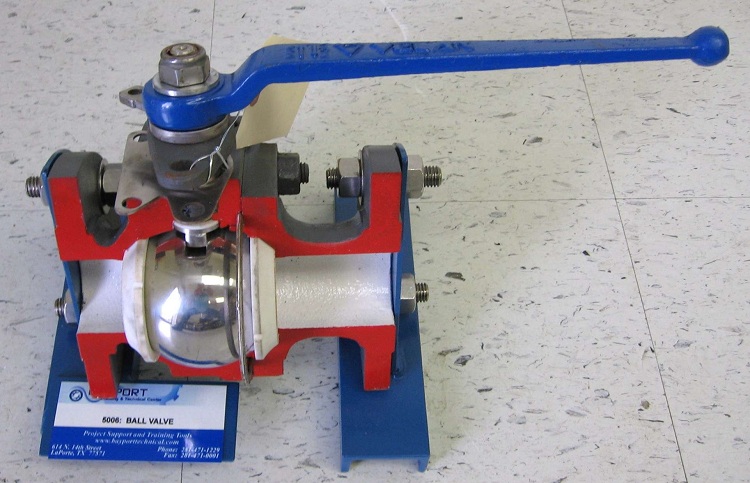

The design of the device consists of:

- housing;

- saddles;

- shutter (ball plug). It is in the device of the locking organs that the main differences in the performance of the devices lie. The floating ball design is installed on pipes with a diameter of up to 200 mm. A cork that does not have a rigid connection with the spindle moves and is pressed by the pressure of the working medium to the o-ring, creating an excessive load on it with large diameters, making the device difficult to operate. The design with the ball in the supports is equipped with a trunnion (axial protrusion) in the lower part included in the special recess, the saddles are pressed under pressure to the surface of the cork. The design is more complex and expensive, but allows you to use significantly less effort, controlling the crane, both manually and using a drive;

- handles (for manual control);

- spindle transmitting force from the handle to the shutter.

The base of the device is made of cast iron, steel, bronze or brass. The stopper plug is made of steel (chrome steel) or brass. Saddles - made of Teflon or Teflon. Polypropylene constructions have minimal threaded connections. They can be installed by arranging the wiring in an apartment, a private house. The service life of metal devices is five years, siluminovye (neglected by many experts) - up to two years.

The colors of the handles (levers) indicate the nature of the working environment:

- red - for hot water, heating systems;

- blue - for cold water supply;

- yellow and black - for gas pipelines.

Couplings made of ball brass

They are made of forged brass and are recommended for installation on small diameter pipelines. If leaks occur, simply tighten the nut by pressing on the Teflon packing. The operational resource is designed for twenty thousand cycles of opening and closing.

The brass device is characterized by such operational qualities:

- durability and reliability, lack of need for lubrication, technical, maintenance, repair;

- leak tightness;

- the ability to install in any position;

- increased traumatic safety of the handle;

- suitability for work at a working pressure of up to 1.6 MPa and a temperature of up to + 150º C.

Steel ball valves

The device consists of a solid spherical body and cylindrical pipes. The sphere structure made of stainless steel is devoid of bolted connectors. This eliminates leakage under pressure of the working medium.

Steel ball valve is characterized by:

- shutting off the flow of working fluid at high speed;

- simplicity of installation and management;

- lack of need for special maintenance, replacement of parts;

- resistance to high temperature of a working environment;

- profitability. It is believed that these devices are the best choice, based on the notorious ratio of cost and quality of the purchased product.

What to look for when purchasing and installing a ball valve

When selecting shutoff valves, it is recommended that you first draw up a clear idea of the following parameters related to its subsequent operation:

- section of pipes in the pipeline system;

- the possibility of hydraulic shocks that will affect the ball valve;

- type and aggressiveness of the working environment with which it is necessary to contact the shutter plug (ball);

- quality of the crane body, which will ensure trouble-free operation.

Domestic manufacturers (like others working in the post-Soviet space) mark valves according to GOST.The products of foreign companies are equipped with a standard metric designation corresponding to the nominal diameter of the pipe.

Metal products are noticeably heavier than plastic, the difference is easy to determine by simply holding the device in your hand. A brilliant shutter device is a sign of quality; gloss is obtained due to the costly pollination of brass with nickel or chrome.

The ball valve is installed independently using the following methods:

- Flanged. For flange mounting, flat rings with bolt holes are superimposed on both sides of the valve onto the bolts. By tightening the bolts, docking and subsequent fixation is achieved.

- Threaded. The locking device is installed on the applied thread.

- Welded. Stop valves are welded to a specific section of the pipeline. The reliability of the connection is undeniable, but the repair or dismantling is complicated.

Getting Started Installing Ball Valve

The first step towards installing the device is to choose the place where it will be installed. In cramped conditions, it is important to correctly determine the length of the handle of the locking device, whether it will be possible to normally turn the long or short handle at the place where the crane is planned to be installed. On a vertical pipe, the location of the handle does not matter. On a horizontal pipeline, the handle of a ball valve must be placed at the top, the permissible deviation from the vertical cannot exceed 45º.

The method of mounting a ball valve depends on the material of the pipes from which the pipeline is assembled

Step two - a crane with certain parameters is selected. At home, the choice usually stops at a ball valve with threaded connections. A locking device with flanges will be needed with a pipe diameter exceeding 40 mm.

The third step is to clarify the diameter of the pipes on which the device will be installed, and the types of thread at the ends of the pipes at the installation site.

Fourth step - clarification of the direction of fluid flow in the pipeline and the required type of thread on the tap, depending on this factor. This clarification may not be necessary, since most locking devices can be installed on either side, regardless of the direction of flow. But some models of ball valves have an arrow - indicating the desired direction of fluid flow. They can be installed only in a certain way, due to the design features of the device.

Installation of metal and plastic ball valves

When installing a metal device, the threaded connection is sealed, for example, with an FUM tape. The tap with a sealed connection is not screwed fully, but so as to ensure convenient use of the handle. Upon completion of installation, you should immediately make sure that there is no leakage.

When installing a plastic pipeline, it is necessary to select all the elements (fittings, pipes, locking device) performed by one manufacturer. Installation will require polyfuse - a special soldering iron for polymer structures in the form of a flat heating element. To solder polypropylene products, it is necessary to heat the polyfuse to 260º C. The valve and pipe are inserted into the nozzles on the sides of the polyfuse and heated at the same time, no more than 6-10 seconds. Softened elements are removed from the nozzles and immediately docked. Cooling completes the soldering process.