A gate valve is a special type of shut-off equipment that is used in systems for supplying and transporting substances of various properties and consistencies. Such equipment is used in the oil and gas industry, in transit pipelines, in housing and communal services. According to the design and configuration features, they are divided into types. Each of them has its pros, cons and limitations regarding the scope.

Gate valves for pipelines are made not only of cast iron, but also of steel, such models are considered especially durable

Content

Design and principle of operation

To better understand the quality of equipment, you should be familiar with its design.

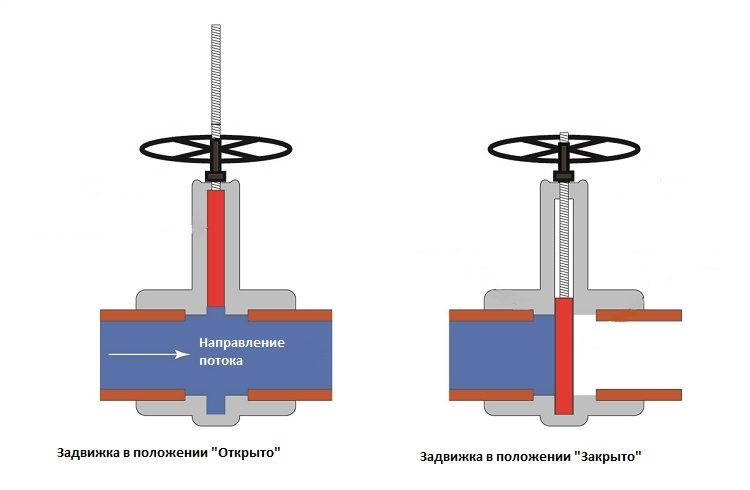

The standard flange gate valve includes a cover and a housing, into the cavity between which the working medium passes under pressure. And then different types of structures already exist: for valves with a non-rising spindle, the running unit is located in this very medium (often water) and remains immersed in it during the entire open / closed phase cycle. Devices with a retractable spindle are not made that way: their chassis in the “open” position rises to the level of one shutter stroke. In such a device, the assembly is connected at one end to the shutter and progressively lifted by rotation of the travel nut.

Inside any steel flanged gate valve, special seats are installed, which are located differently depending on the type of device (for wedge gate valves they are installed at an angle). During the installation of the “closed” phase, their sealing surfaces converge with the seals of the running unit (wedge or rod). The running nut, which forms a threaded pair with the spindle, rotates, and through this movement, the regime changes.

In addition to other parameters, such locking devices as steel gate valves are distinguished by the principle of operation. There are manual, electric and pneumatic actuators.

The valves are attached to the pipes using flanges, this is the most reliable connection and it is suitable even for high-pressure lines

It's important to know! The latter type of device is distinguished by the fact that motion during phase change can only be translational and often this affects the response speed of the equipment.

Device advantages

Steel gate valves for wastewater - a popular type of stop valves for pipelines. Their relevance in the market and in municipal structures is explained by a number of advantages, among which:

- high level of tightness. This will allow you to maintain the desired pressure and speed of transportation of the substance in the pipeline;

- compactness (especially in comparison with a ball valve) in terms of construction length. As for the height, in this regard, the flange valve loses to both the ball valve and the disk valve;

- universality. If other types of equipment (for example, a butterfly valve) are not able to work with many types of media, then steel valves are used to transport and supply water, oil, gas, chemicals, sewage, and much more;

- relative simplicity of design. Compared to a ball valve, a flanged gate valve is much simpler.This means that there will be significantly less worries with its installation, maintenance and replacement.

Cons and disadvantages of gate valves

Despite the abundance of useful qualities, this device is not perfect and, like any product on the market, has certain disadvantages. They are important to consider when choosing the hardware for your system.

A large construction height is a drawback of the valve, since it requires a large space for installation on a closed type pipeline

So, the disadvantages of steel wedge gate valves with a retractable and non-extendable spindle are:

- features of sealing surfaces;

- relatively high construction height. This is especially true for gate valves with a retractable spindle, the height of which in the “open” state is one more shutter height. Therefore, when using such equipment will need a large area;

- inability to use as a regulatory device. This type of flange locking device is designed for only two modes - “closed” and “open”;

- low response speed. Such an advantage of the device as smoothness has a downside. The progressiveness of the movement implies a large cost for it in time, which is reflected in the shutter speed.

Location classification

There are two types of valves relative to the configuration, and specifically - the location of the running unit (spindle nut).

With extendable spindle. Such flange devices are characterized in that the spindle is not immersed in the working substance. Its features serve as an aid to certain advantages and disadvantages:

- durability. Since the chassis is not exposed to substances passing through the pipes (and this may be aggressive chemicals), such flange devices will last much longer and with fewer breakdowns;

- ease of repair and maintenance. Due to the already mentioned design features, device parts remain easily accessible, they are easier to repair and replace, as well as to keep under control.

A slide valve with a retractable spindle is a more practical and reliable option than a model with a non-extendable spindle

It's important to know! It is because of the ease of maintenance that the retractable type of spindle is most often used in the oil and gas industry, where a breakdown can result in impressive financial costs and even a danger to the ecology of the environment and the life of workers.

With non-extendable spindle. Such a steel wedge gate valve can be safely used for supplying and transporting sewage water, hot and cold water supply. It is less durable and safe than with a retractable part, but takes up less space.

Marking and Views

Gate valves are of various types according to the material of manufacture (cast iron, steel), according to the type of shutter (hose, wedge), according to the location of the running unit (retractable / non-extendable spindle), according to the principle of operation (manual, electric and pneumatic actuators) and by the method of fastening (most often flanged).

Most often in industry and housing and communal services steel devices are used to transport water, since the material itself is not as heavy as cast iron, but in terms of strength and durability it is not much inferior to it.

Wedge gate valves for wastewater distillation are distributed into another three subspecies depending on the type of valve. It can be a hard, disk or elastic wedge. The first type is characterized by imperfections regarding the fit, however, a simpler design. The elastic wedge is, in a sense, the most perfect subspecies, however, and it has certain disadvantages.

In order to better understand the varieties and choose the right equipment, you should carefully understand the labeling of products.

The question often arises, how to decipher the marking of steel gate valves? Take, for example, a 30s41nzh valve.

Numbers and letters on the valve body indicate its type, material of manufacture, size and other technical data

Here, the number 30 indicates the type of shutter - in this case, it is a wedge. “C” is the index of the material from which the product was made. In our case, steel is meant.

41 is the item number accepted by the standards. Often this number is set to 5 - this means that it is possible to install a gear on the equipment to simplify control, or 9, which means that the device is equipped with an electric drive.

"NJ" - that is, stainless steel - is the material from which the shutter or protective surfacing is made on it. Such equipment is not exposed to water and chemicals. substances.

"Ru" - the pressure of the working substance (industrial or waste water, oil, gas, etc.).

“Du” is the designation of the connecting diameter to the communication system.

And finally, the number 100 means the diameter of the product.

Gate valves are devices used to block the movement of a working medium through a pipeline. Due to the design features, they can be installed on highways for various purposes, including those transporting gas. However, these devices also have a number of disadvantages that must be taken into account when choosing a product of one type or another.