To make the supply of water and heating to buildings of various purposes comfortable and safe, it is important not only to choose the right pipes and to lay them well. Every detail is important here, including reinforcing equipment. Gate valves are used in all types of steel systems. To choose the right product, you should familiarize yourself with its features, pluses and minuses.

Content

Main characteristics

Wedge gate valve is one of the types of stop valves for pipelines for various purposes.

It is used for hot and cold water supply systems, heating communications. In addition, the device is used in systems designed to transport liquid hydrocarbons, compressed air, as well as other chemicals, the influence of which the material of the product is immune.

Wedge gate valves are also popular in the gas transmission and oil industries, in the energy sector, and in housing and communal services.

Such a part is used exclusively in the role of a locking element, since the operating mode involves only two phases - open / closed (i.e. without intermediate phases).

A wedge gate valve is a variant of stop valves, with its help you can only block or open the movement of the carrier through the pipeline

Such a device is made of various materials by different methods. Depending on this, they are divided into types that are used for specific purposes, depending on the properties.

Pluses of the locking device

The popularity of brass wedge gate valves in the market of sanitary equipment and in the industry is justified by the significant advantages of parts. Among them:

- simple equipment. The simplicity of the product design makes it easier to work with it, as well as installation and repair;

- short construction length;

- low hydraulic resistance;

- universality. Steel is a dense and durable material, immune to corrosion and the influence of certain chemicals. Therefore, such a device can be used in a wide variety of systems both in terms of pressure, transport speed of the working substance, and in volume. In addition, the spectrum of substances itself is wide, for which valves can be used;

- durability. Due to the properties of the material and the simplicity of the design, a wedge gate valve with a non-extendable or extendable spindle will serve for a long time and without interruption, and if repairs are required, it will not be too complicated and expensive;

- the ability to transport substances in both directions;

- ease of use. You do not need much effort to open / close. In addition, to facilitate this task in large systems, a gearbox is installed;

- smoothness at closing. The use of equipment such as a brass gate valve with a non-rising or retractable spindle helps ensure safety from water hammer, in some cases leading to deformation and even violation of the integrity of the pipeline.

Wedge gate valves are manufactured in a wide variety of sizes and are even installed on pipes made of polymers.

Cons of gate valves

Despite the large number of advantages, still this equipment is not perfect. In some cases, it is recommended not to use it or to observe certain rules during operation. Its main disadvantages and restrictions on use include the following:

- high construction height. This is especially true for slide gate valves. When opening them, you need a space with a height greater than one diameter of the pipeline;

- the duration of the opening / closing procedure. This makes the system less operational, which in some cases complicates the work with it;

- the inability to work with substances containing large solid inclusions;

- low level of wear resistance of sealing elements in the housing and shutter. This drawback is fraught with additional difficulties and repair costs. Parts with a retractable spindle are distinguished by slightly better performance in this aspect, since it is not subject to the influence of an aggressive environment;

- small allowable pressure drop across the valve. That is, with a larger difference, device malfunctions are possible;

- the relatively high time required to unscrew and screw the device.

Materials and manufacturing methods

Gate valves with extendable and non-extendable spindles come in different types depending on their properties and design features. This device can be made by casting or welding. The first method is typical for steel products and titanium alloys.

Production technology is not complicated:

First, the steel sheets are fed to the conveyor, having previously checked them for rust or scale and removed, if necessary, these shortcomings.

Then they are stamped. This is done on a special machine that performs plastic deformation of the material by clamping the sheet between the upper and lower surfaces of the molding device. The resulting blanks of wedge gate valves with a retractable and non-retractable spindle are welded, carefully boiling all sections. Seams are checked for strength and durability.

Casting is also quite common. This method is applied to parts made of cast iron, aluminum alloys, and also for steel. However, parts made in this way are slightly worse in terms of strength and durability. Stamp-welded gate valves with retractable and non-retractable spindles are made of more durable raw materials and are more durable in design.

An important detail is also the sealing elements. They are produced in different types:

- with rings (brass or PTFE);

- without rings;

- with protective anticorrosive cladding;

- with rubber, which can be covered with a wedge (if the valve is wedge).

Wedge Gate Valve: Classification

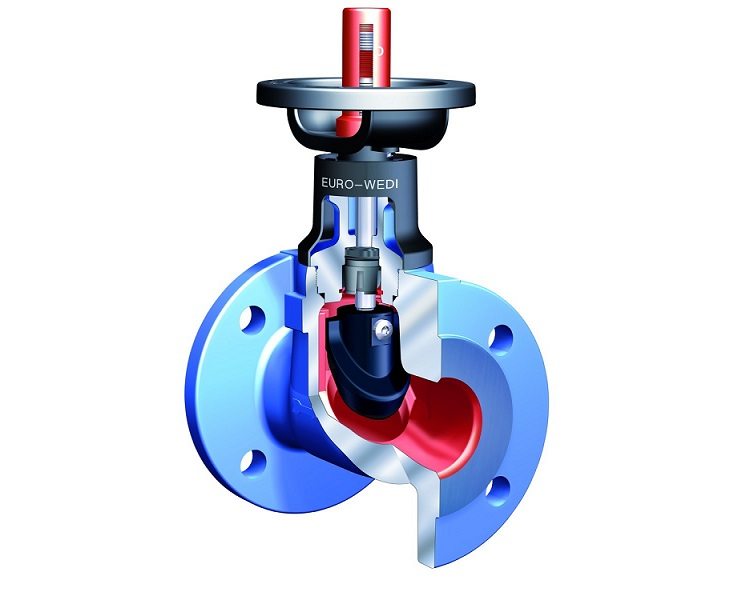

The specifics of brass wedge gate valves with a retractable or non-retractable spindle is the presence of a wedge - a device that performs the function of a shutter, entering the “closed” position tightly between two saddles, located at an angle to each other.

The tightness of the device and the simplicity of working with it depends on the type of wedge in the valve

Depending on the type of wedge, they are classified into types.

Hard wedge. Such a device will provide reliable sealing of the shutter. However, there are certain drawbacks: the first is that in case of malfunctions (jamming) it will be difficult to cope with such a problem, and impressive physical strength will be required; the second - to achieve the effect of tightness, you need to very accurately calculate the size and angle between the saddles; third, a valve (with a retractable and non-retractable spindle) will be difficult or even impossible to open if there has been a significant difference in temperature of the working substance, as well as if the equipment is damaged by corrosion or worn out.

Double disc wedge. This is a better product. Although this type has a more complex design than the previous one, however, it is more than paid for by its advantages. Firstly, the use of such valves with a sliding and non-sliding spindle reduces the likelihood of jamming.Secondly, less effort is required when working with them. In addition, in devices of this kind, shutter tightness is more easily achieved, because the discs themselves adjust to the angle between the saddles. This makes minor errors in the calculations insignificant.

Elastic wedge. It combines all the advantages of the two previous valve gate valves. In the case of using this type of locking equipment in structures with a retractable and non-retractable spindle, precise adjustment of the housing is not necessary, as in the case of a rigid analogue, and its design is simpler than that of a double-disk one. In fact, this device is the same double-disk wedge. They differ only in the connecting element - in this case it is elastic. Of course, this reduces the ability of the disks to self-regulate under the body of the product, however, it provides greater resistance to temperature changes.

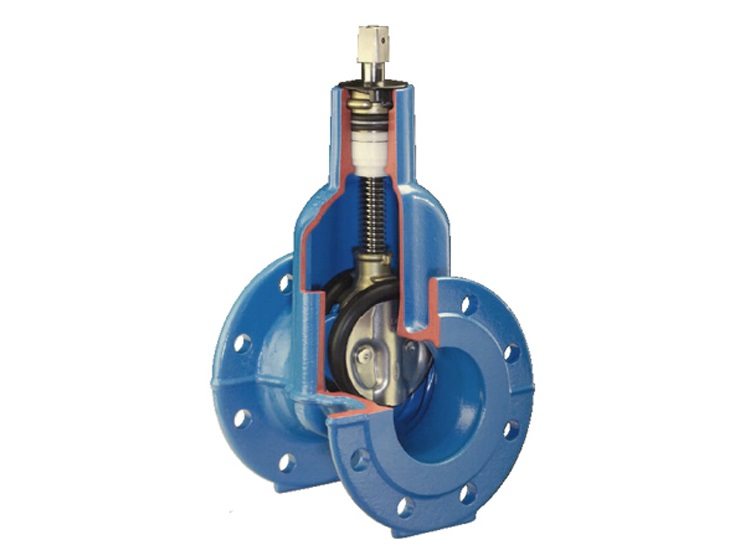

Gate valves with extendable and non-extendable spindles

When choosing reinforcing equipment, pay attention to the location of the running assembly, which is a threaded spindle-nut connection. The scope of the possible application of the device directly depends on the type of this connection.

This element happens in two forms:

Retractable. This is a type of device with a spindle located outside the valve body, with the lower end connected to the valve and in the “open” position it extends to the height of one valve. Such devices are used in conditions of increased requirements for equipment reliability. They are perfect for such purposes, as they provide simple and quick access to the travel unit with a spindle and prevent destructive processes due to the influence of the working environment.

Non-retractable. This is a design with a spindle immersed in the working medium. Of course, such a device outperforms devices with a sliding spindle in terms of compactness and building mass, but is significantly inferior in terms of durability and wear resistance.

A wedge gate valve is one of the most popular types of valves, as it is reliable and easy to maintain and use. Its connection with pipes, as a rule, is flanged - it allows you to repeatedly mount and dismantle a section of the pipeline. And this is important for quick and timely repairs if necessary.