An American faucet is a device that greatly facilitates the work with plumbing. This type of shut-off and control valves can replace during installation an assembly made up of several parts, including a coupling and a special nut. Such a device is used, as a rule, in water and gas piping systems assembled from different types of pipes - steel, copper, and polymer.

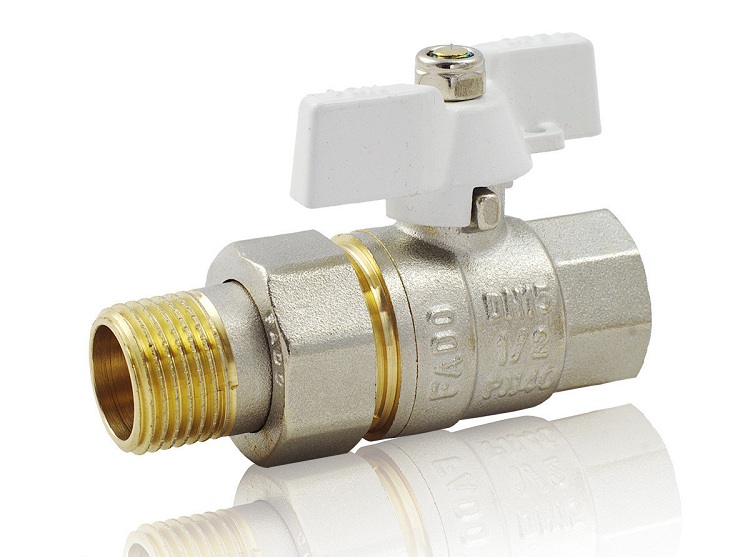

Ball valve "American" is a type of shutoff valves that can be installed on systems, devices and devices for various purposes

Content

Device and features

A ball valve with an American connection is a fixture, the main components of which are a body that joins with two pipes and an overlapping element - a ball. The most popular material for these products is steel. In addition, American ball valves can be made of brass, cast iron or PVC.

Inside the ball valve is a ball with a hole inside. The dimensions of the passage can be one inch, equal to the cross section of the pipe or less than it.

The ball is connected to the stem and a lever that regulates the operation of the device (when the handle is turned, movement is transmitted to the ball through the rod). Due to this, it is possible to control the transported medium. If desired, you can adjust the amount of passing substance or completely shut off the flow. In the closed position, the hole of the ball device is rotated perpendicular to the direction of flow and nothing passes through it.

Note! If the valve leaks in the closed position, then, perhaps, the connection is not tightly mounted or the device itself is of poor quality.

Purpose and benefits

Ball devices greatly simplify the work with plumbing. When installing them, pipes are not rotated, which is very convenient. This is possible due to union nuts on the tap itself, which carry out the connection of the pipeline parts. Under the cap elements, as a rule, a fitting and a gasket are located.

A special clamp of axial type performs the function of adjustment. In this case, the rotation of some nuts is carried out. The operation of the ball device is based on the mutual rotation method. This type of valve allows you to connect pipes reliably and with a high rate of tightness. The latter is provided with union nuts equipped with washers.

In addition, this connection ensures the safety of pressure in the system. His jumps are one of the main complications in the operation of pipeline structures. Ball valve avoids this problem.

Advice! It is recommended that products of this kind be installed during the installation of sensors and counters. Cranes avoid pressure loss, which helps to obtain more accurate instrument readings.

Buying such a device allows you to cope with many problems and ensure a reliable connection of pipeline elements. Most often, ball valves are used when installing radiators for heating. Thanks to this device, it is possible to control the pressure and pressure of the liquid in the system without problems.

A distinctive feature of such shut-off and control valves is that thanks to it, it is possible to adjust the environmental indicators in the system with your own hands. It is very convenient. In addition, the installation of a ball device simplifies subsequent dismantling. In which case, the radiator can be removed without much difficulty. The connection with the help of an American is quite popular not only when installing radiators on heating, but also when installing heated towel rails, boilers, pumps and many other devices.

Types of Ball Devices

In order to purchase a device that is suitable for your particular case, it is worth studying its varieties and their characteristics.

American connections have two types of seals:

- conical;

- flat.

The main indicator by which this type of shut-off and control valves is subdivided is the shape of the product. In their form, ball devices are divided into three types:

- direct;

- angular;

- combined.

The first type is used in cases where it is necessary to connect two pipes that are located on a straight section of the pipeline. Angular ball valves with an American set on the corners of the pipeline. The angle size is usually 90 degrees. Angled American crane is a compact and convenient solution for connecting the pipeline. Combined devices may include various elements that perform different tasks. Combined are much less common than the first two types, since they are somewhat more expensive and more difficult to install.

In addition, ball valves are divided by the shape of handles into:

- taps with butterfly handles;

- cranes with handle levers.

Butterfly handles are usually mounted on devices that are small in size. This is convenient due to the fact that it takes a minimal effort to turn such a handle. Cranes with handle levers are mounted in piping systems with large pipe diameters. To turn the handle, the lever requires more effort and free space.

Ball devices are also divided by size. The most common species is a one-inch American. There are two-inch products, however, they are less common.

There are several subspecies of this device:

- Decorative - has the same design as a conventional ball valve, however, differs in appearance. As a rule, this subspecies of the device has a non-standard design and is used for a variety of interiors.

- Special - produced in a single version. Used to solve non-standard tasks.

- Crane (BB) - this type has an internal thread on both sides.

- Crane (HH) - has an external thread on both sides.

- Crane (HB) - includes both external and internal threads.

The cost of a ball valve, as a rule, depends on the country in which it was manufactured, as well as on the manufacturing company.

The main stages of installation

Consider the main stages of installation of a locking and regulating ball product with an American.

1. Before starting installation, it is recommended to carry out preparatory work, which includes: cleaning the pipes from rust and other defects (for example, burrs), marking the pipes with a marker.

Important! Before installing the crane, it is worth checking whether the regulating handle of the crane makes a full revolution.

2. The winding up of the device takes place in 4–5 turns. To achieve the desired level of tightness using special connecting seals. These include flax thread or FUM tape.

3. After installing the valve, check if everything is working well.Be sure to turn on the water and make sure that the structure does not leak. If water starts to drip from the docking points, you just need to tighten the nuts stronger.

Ball valves "American" can greatly simplify the installation and dismantling of pipeline structures. No special tools or building skills are required for installation. Ball valves have different variations in shape, size and characteristics, which makes it easy to choose the product needed in each case. For the correct choice of the ball valve, it is still recommended to consult with specialists who will select the part, taking into account all the requirements for the designed pipeline.