Today, without much work, it is possible, using separate elements, to construct a sewer system of any configuration. One of the necessary elements for assembly is a sewer outlet - a shaped product that is used to rotate the pipe at a certain angle. Bends are made from different materials, as well as pipes for drainage systems - from polyvinyl chloride, polyethylene, polypropylene, and, of course, steel and cast iron. Although the latter for sewage systems are used less and less.

Content

Main characteristics

Branches perform the function of turning the sewer pipe to the required angle. They are used for the installation of drainage systems in workers and residential buildings. Thanks to the smooth walls of the plastic parts, the probability of accumulation of debris and clogging of the system is minimized. In addition, plastic has one indisputable advantage over metals - it has resistance to corrosion. A plastic element is considered sound-absorbing, so it practically does not emit noise when moving drains.

Advice! Using combinations of taps in the sewer design, it is possible to obtain various angles of rotation of pipes (from 30 to 90 degrees). But do not make too strong bends, otherwise such places will be easily clogged with garbage.

Also, polymer parts are characterized by good heat resistance. The temperature of the working environment for PVC products is up to 95 ° C. Plastic bends are able to work with chemically active environments.

The most popular are bends with internal hole sizes of 110 and 50 mm.

Standard indicators of angles, as a rule:

- 30°;

- 45°;

- 87°.

Technical data of some types of bends are presented in table No. 1.

Table 1

| DN (mm) | Weight, kg) | Length (mm) |

| 300 | 43,9 – 65,9 | 450 |

| 250 | 23,0 – 46,7 | 375 |

| 200 | 14,9 – 39,0 | 300 |

| 150 | 6,1 – 13,3 | 225 |

| 125 | 3,8 – 6,2 | 190 |

| 100 | 2,2 – 5,0 | 150 |

| 80 | 1,4 – 2,8 | 120 |

| 65 | 1,0 – 1,7 | 100 |

| 50 | 0,5 – 1,0 | 75 |

| 40 | 0,26 – 0,5 | 57 – 60 |

| 32 | 0,19 | 48 |

| 25 | 0,11 | 38 |

| 20 | 0,06 | 29 |

| 15 | 0,04 | 28 |

In addition, there are options for bends with access to other diameters. Such bends are used for various non-standard combinations of the sewer system

Types of branches for sewage by materials

All types of branches for sewers must comply with accepted standards according to GOST. This allows us to simplify the process of product selection and installation. First of all, all sewer branches are divided according to the material of manufacture. There are products from the following materials:

Polyethylene. Products made of this material are black. The connection of polyethylene bends is carried out using special fittings - couplings. Such fittings incorporate a spiral, which is heated by welding and forms a sealed connection after cooling. In addition, there is a butt joint, for which the ends are heated and pressed until they solidify.

Branches made of polyvinyl chloride (PVC). Products from this material have the largest assortment and are in great demand among customers. Docking of PVC sewer drain is made using a special bell, which is worn on a smooth pipe. The main advantage of this system is its ease of installation and quick installation. The color of such products is usually gray. Brown elements are used in open sewer systems, which are located on the street in private households.

Important! It is necessary to use bends of one kind. If necessary, you can purchase special adapters that will allow you to combine any product.

Polypropylene Equipped with sockets and smooth ends for easy connection with each other. Such products are recommended for use in structures that are made of the same material. Wastewater is withdrawn at a speed of 4 to 7 m / s.

Bends for corrugated pipes. Installation of these products is carried out using special couplings. In addition, on each side of the device is equipped with a sealing ring. Used to connect pipes that consist of different materials.

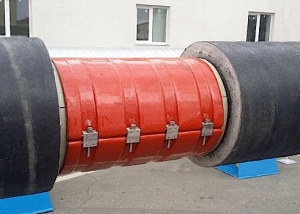

Galvanized steel. Durable material used for the installation of sewer structures. However, galvanized steel elbows do not resist corrosion as well as plastic products. When welding pipes, as a rule, the protective layer of galvanization is damaged and rust can occur at the weld site.

Stainless steel. It has excellent anti-corrosion performance. In addition, stainless steel parts are more reliable and durable than plastic counterparts.

Mounting Features

When performing the installation of these devices with your own hands, it is worth remembering a number of rules. The element is connected to the pipe due to special gaskets. As a rule, they are already included in the tap set. If there are no such parts on the drain for the sewer, in this case the rubber ring must be purchased separately, then placed in a specially prepared recess in the drain and proceed with installation.

In some cases, glue is used to connect the sewer structure to the drain. This type of installation is considered more difficult and is not very common. Adhesive docking does not require any seals. When combining in the design of pipes made of various materials, it is recommended to use sealing cuffs that will ensure a reliable, tight connection.

PVC bends are the easiest to install. Their installation does not require special building skills and complex tools. Such elements for sewage are simply inserted into each other. The result is a sturdy and airtight construction. This option is most often used when installing bends with your own hands.

PVC bends are equipped with sealing rubber, so their installation is simple and does not require the use of sealants

In addition, all bends can be divided into:

- welded;

- cold bent.

Helpful information! There are special segmented bends that are used in cases where it is necessary to combine the massive design of the pipes.

Shaped products made of steel can be made of different types of metal: alloyed, stainless steel, etc. Their scope of use is identical to plastic sewers.

Joint Sealing

The sealing indicator is very important, since the performance and reliability of the entire system depends on it. When installing the structure, it is worth paying maximum attention to this aspect, especially if the installation is carried out personally.

Strengthen the joints between fixtures and pipes preferably with special sealants, which can be purchased at any hardware store.

They are divided into two main types:

- with acidic environment (cheap);

- neutral (more expensive).

The use of a sealant is desirable in any case, because it adds reliability to the joints, even if PVC products with sealing rings are mounted. Acidic sealants are not allowed when connecting metal products for sewage. Therefore, when purchasing a sealant, you must carefully read its composition.

When installing sewer structures made of cast iron material, the use of sealants is mandatory due to the fact that the walls of such products cannot be perfectly smooth, like plastic parts. A suitable option in this situation is liquid silicone.

Additional sealing methods

In addition to sealant, there are other ways to seal joints:

Epoxy adhesive. Such a connection is characterized by high strength and reliability. However, it has its own minus. The connection using epoxy glue is one-piece, so it is impossible to dismantle the pipes without damaging them.

Hemp or tar. They are used in the case of mounting devices made of polyvinyl chloride on pipes made of other materials. The application of these connecting materials must be done as carefully as possible. Two thirds of the length of the end face of the part is applied to the selected material. Next, the end is inserted into the socket and poured with cement.

Technical sulfur. Previously, this method was the most common, since sewage was collected from cast-iron pipes. However, plastic products with their appearance took first place in the market and now this method is used much less often. It is suitable when it is necessary to combine sewer systems from different materials.

Bituminous mastic. It has proven itself in the installation of ceramic bends with pipes of the same material.

Sealing tape. The use of sealing tape (e.g. FUM tape) is considered a temporary measure. The most unreliable way to seal joints.

The life of the sewer system depends on the correct selection of components for sewage, as well as on the implementation of installation work, taking into account certain rules. Before starting installation work, it is worthwhile to study all the technical characteristics of the branches and their connection methods with sewer pipes. If necessary, you can always consult with specialists. Strict adherence to the installation rules will allow you to get a reliable design that does not require repair for a long time.