Pipe sealing is the organization of complete obstruction of gaseous and liquid substances from pipes. This event is very important, but, as a rule, insufficient attention is paid to it, which over time negatively affects the integrity of a particular pipeline structure. Re-sealing is much more difficult than performing it immediately when installing the pipes.

When installing water supply, heating or any other system, special attention must be paid to sealing the joints

Content

Properties and features of sealants

Today, in the building materials market, you can find a wide range of sealants for different types of pipes, which allows everyone to choose the material that is economically and practically practical.

Important! For plumbing systems, installation of sealing materials is considered mandatory.

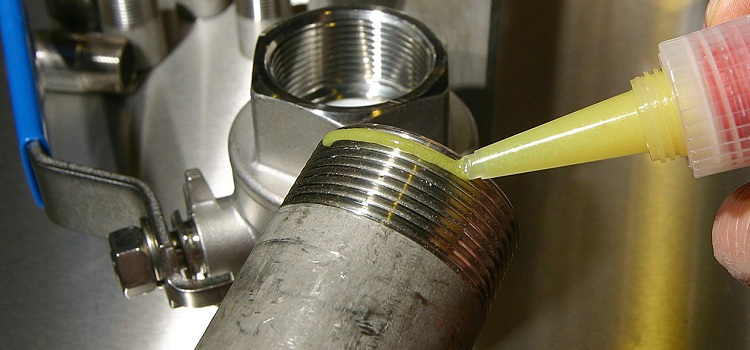

The sealant is not recommended to eliminate the leak, since it can cope with this problem only for a while. Sealants are used to eliminate leaks in pipeline structures. These materials are mounted in places where pipes are interconnected or joined with fittings.

They are used for various types of fittings, but this is especially true for threaded and compression models. From a structural point of view, such fittings are prone to loosening nuts, so they need additional fixation to the glue.

Sealing material is not ordinary glue, so it is not able to cope with a crack in the pipe. Such compositions minimize the likelihood of a crack. They are often used for sewer communications. This is due to the fact that modern communications are made from polymers, which are manufactured with the expectation of quick installation without the use of special equipment.

In what cases is it necessary to use sealant? Pros and cons of using

In some cases, the sealant may not be needed, however, situations often arise that require its use. Consider them:

- violation of installation technology;

- poor quality of rubber o-rings or their complete absence.

Sealing material for sewer pipes is used internally and externally. Specialists recommend the use of sealants as additional protection in all cases. From a financial point of view, this is associated with high costs, however, and the reliability of such a system increases, which allows to protect communication from breakdowns as much as possible.

Consider the advantages of using sealing compounds:

- such materials increase the sealing performance of the structure, which positively affects its operational characteristics and service life;

- the possibility of reinforcing the sections where the pipe connection is performed;

- ease of application of sealing materials.

Among the disadvantages of using sealants, only two can be noted:

- increase in financial expenses during the installation of communication;

- time costs.

Sealing agents, if necessary, are used at the joints of pipeline segments, regardless of the type of connection

Types of pipe sealants

Today, there are several popular sealing materials that differ in structure and application method. Consider these materials:

- liquid plumbing compounds for sealing pipes;

- FUM tape;

- hardening compositions for plumbing communications;

- sealing with linen thread.

- polymer thread.

Liquid synthetic compounds for sealing pipes. This class includes modern polymeric materials, which are characterized by high ductility even after solidification. Such sealants have one distinctive feature - when applied, they repeat the shape of the parts in the connection node. After solidification, they form a solid gasket filling the joint. Such a gasket is considered very reliable and can not be displaced by the pressure of the liquid in the pipe.

Some varieties of liquid sealants cannot be used for pipes transporting hot water. This is due to the fact that, at high temperatures, such compositions are very softened and lose their beneficial properties. The most common liquid sealant today is a silicone-based compound. Working with such a sealing compound requires great care. Consider two basic rules for working with such a hermetic material:

- protective rubber gloves are required;

- the room in which the work is carried out should be well ventilated, since acetic acid is actively released when the silicone sealant dries.

The composition of liquid sealants includes aggressive substances, so when working with them you need to use protective equipment for hands and respiratory organs

FUM tape. Such a tape is a popular sealing agent that is used for all types of threaded connections. However, such a tape has its drawbacks, the main of which is - if the pipeline is subject to vibrational influences or various kinds of displacements, the FUM tape can allow leakage at the joints. Otherwise, this tool is considered very reliable. The tape is tightly wound and does not require the use of special tools.

Hardening compositions for plumbing communications. Perhaps the most extensive group of sealants for sealing pipes. Experts advise not to use such substances in everyday life. This is due to the fact that the technology of hardening sealing materials is in the process of development. Today they are actively used in industrial enterprises.

Sealing with linen thread. Previously, hemp (hemp fiber) was used instead of flax, however, now its use has ceased. Flax fiber is an organic substance that is highly susceptible to decay.

Note! On pipelines transporting hot water, flax fiber dries and becomes brittle. Therefore, it is strongly not recommended to use such a sealant for heating pipes.

Polymer thread for sealing threads. The polymer thread resembles an FUM tape in its characteristics. However, such a sealant is more reliable and difficult to use than FUM tape. The use of a polymer thread guarantees high tightness, but such a material must be applied evenly, otherwise there is a danger of thread breakage.

Other pipe sealing methods

There are many other ways to seal pipes, among which there are old, still used by the people.One of the popular old methods is soaking flax in hot linseed oil. Soaking time, as a rule, is about two days. After soaking, the flax is kneaded like dough in lead minium. This method is suitable for different pipelines (including heating pipes).

It is also worth mentioning about sealants for sewer pipes. It is possible to seal the sewer pipe using a very popular method - minting. For sewer communications, which are joined by means of a special connecting element - a bell, chasing with a heel is used. Kabalka is an organic fiber of plant origin, which is impregnated with mineral oil.

Such a sealant for sewer pipes is very reliable and has a long service life. Chasing is carried out with a special tool that resembles a large screwdriver. Thanks to this tool, the heel breaks into the joint. Winding is often performed in several revolutions. After this procedure, the joint of two pipes is covered with cement mortar to increase the sealing performance.

Another of the old methods is to fill the joint with hot sulfur. However, it was almost completely abandoned, since sulfur fumes are very harmful to human health, and can also catch fire.

Tips for choosing the right sealant for different pipelines

For pipes made of polyvinyl chloride (PVC), it is recommended to use rubber or silicone based sealants. Such materials have a long service life and are great for plastic. They grapple with plastic like glue. Rubber and silicone sealants are also suitable for metal-plastic pipelines, since the outer shell of the pipes in this case is represented by plastic material.

Joints in heating communications are recommended to be sealed with special materials that have good heat resistance. Silicone sealants are not suitable for heating pipes. Experts advise combining sealing materials when installing heating systems. In this case, a combination of heat-resistant substance and tape is an excellent option.

When installing metal communications, it is advisable to use special sealing tapes. And the selection of sealant for sewer communication is a more complex undertaking. The composition based on silicone is well suited in this case, however, its cost is high, as well as consumption. Sealant for sewer pipes is best selected depending on the specific case.

Important! For gas pipelines, it is advisable to use sealants that are of high density. This is necessary to exclude the possibility of penetration of gas through the sealing material.

For chimneys, special sealants are used, which are highly resistant to several factors arising in such systems (high temperatures, aggressive substances and condensate). The most suitable option in this case is a rubber-based polyurethane composition. Despite its high cost, it fully justifies itself in operation.

It is recommended to carefully study the composition of the sealing material when choosing it. Modern sealants are resistant to a wide temperature range - from −50 to +200 ° C. Attention should be paid to other properties that vary, depending on the type of sealant. Among these properties: density, strength, viscosity, etc.

DIY sealing process

Consider the phased process of sealing the pipeline with linen thread with paint:

- First of all, it is necessary to prepare for sealing the compound with a sealing substance. To do this, it is necessary to clean the thread and degrease it with gasoline.

- Next, you need to paint the thread with paint and wait a while to make the paint sticky.

- At the third stage, flax thread is applied to the thread. Experts recommend applying the sealant evenly so that there are no protruding or, conversely, empty areas. A small amount of paint must be applied to each layer of linen thread.

- Then you need to twist the pipes. The process of connecting pipes to the thread is preferably performed slowly.

For this type of sealing, enamel paint (PF) is best suited. This event must be approached with all seriousness, since correctly selected and applied sealing material helps to increase the operational life of communication. In addition, it must be remembered that all joints in any case should be collapsible.