At device heating systems Together with determining the type of batteries, boilers, circulation (forced, natural), wiring diagrams, it is important to consider which pipes to choose for heating. If a clear and correct approach to solving this issue is to find out the pros and cons, allowable pressure and temperature for each type of product, then a suitable thermal regime and system operation efficiency will be ensured for many years. Of no small importance is the required distance between the pipes and the heating circuit itself (two-pipe or one-pipe), what elements are needed for one or another and how to use them correctly. For a building under construction, it is important to find out what the features of laying heating pipes underground are.

Content

- 1 Rules for arranging a heating system

- 2 Features of networks with natural (forced) circulation

- 3 Requirements for pipes for heating systems

- 4 How to choose the right pipes for heating

- 5 Types of pipes for heating

- 6 Black Steel Heating Pipes: Cons

- 7 The advantages of steel pipe

- 8 The use of copper pipes for heating

- 9 Features of metal products

- 10 Use of polypropylene heat pipe

- 11 XLPE pipes for heating

- 12 The principle of heating air from a gas boiler

- 13 Procedure if a pipe breaks

- 14 How to ensure a breakthrough sealing

- 15 Some features of using smooth rigid and flexible pipes

Rules for arranging a heating system

The type of heat source that is located in the house affects the choice of pipe to be used for the heating system. If the house is gasified, it is assumed the use of a gas boiler. It is usually equipped with:

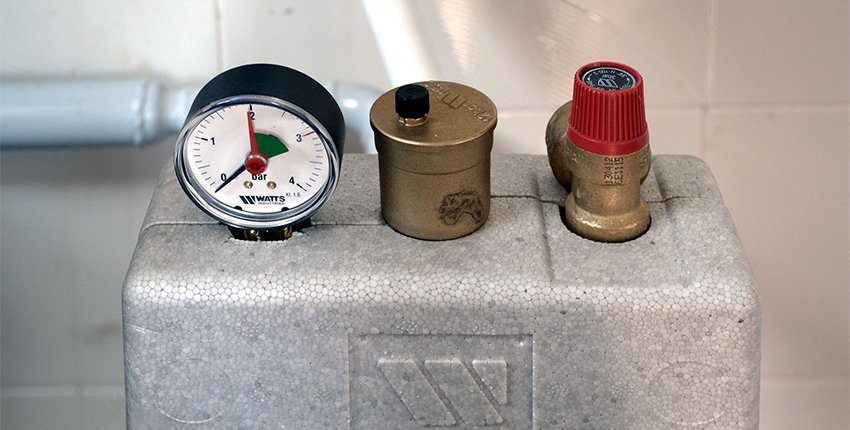

- security elements;

- integrated automation;

- pumps.

If it is not possible to install gas equipment, an electric or solid fuel boiler is selected. When arranging and installing a room heating system, it is necessary to adhere to such rules:

- In heating systems, you can combine different types of pipes. Choosing what kind of heating to do, you should pay attention to their labeling. This information will give an idea of how the pipes differ.

- Typically, with a two-pipe wiring of systems with natural (forced) circulation, a metal-plastic pipe is used for heating (16x2.0).

- With a building area of, for example, 100 m2 the length of the pipeline that delivers water to the radiators from the gas boiler should be less than 25 m.

- If it is necessary to connect a large number of radiators, double-circuit wiring is used, and the pipe for organizing heating should have a large diameter.

- It is also necessary to bring out the gas heating pipe, designed to extract and remove combustion products.

- It is forbidden to install any stop valves between the security system and the boiler (for example, gas type).

- During installation, the specified distance between communications must be observed.

In a forced circulation network, it is best to place a filter in front of the pump. To obtain a complete and more beautiful appearance, the use of contours for heating pipes under the laminate is practiced.

Features of networks with natural (forced) circulation

From the solution of issues related to the circulation of the coolant also depends on which heating pipe is better to choose. Pipeline schemes suggest one of two distinct motion options:

- with forced circulation;

- with natural circulation.

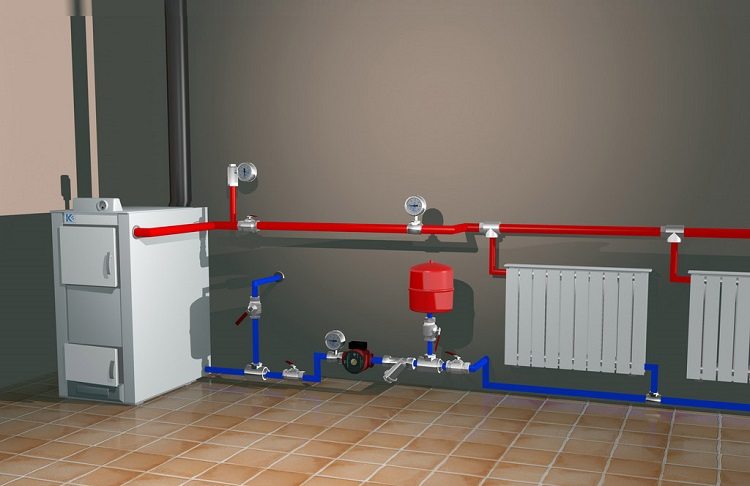

In the first version, the system is equipped with a pump that pumps water. In the second case, the coolant moves due to natural convection. In this case, additional costs for creating circulation are not required and the system can function only thanks to the heat from the gas boiler.

Note! A circuit with natural circulation requires a complex hydraulic calculation, maintaining the distance between the heating pipes and slopes.

Forced circulation systems allow increasing pressure, increasing the efficiency and efficiency of the gas boiler. Their functionality is not affected either by the temperature of the water in the heating pipe, or by the length of the communications, or by significant level differences.

A forced heating system is considered to be a more effective heating system, in which a circulation pump is responsible for the movement of the coolant

If with natural circulation it is possible to create a pressure of no more than 1.5-2 bar, then with forced circulation - 2-4 atm.

Requirements for pipes for heating systems

Undoubtedly, heating pipes play a decisive role in maintaining the integrity of the systems. They ensure the delivery of hot water from the gas boiler to the battery complex. The most important requirement for a pipe is that it must be strong and good if this characteristic is maintained throughout the entire operational life.

Heating pipes (smooth or flexible) must not be oxygen permeable, since otherwise rusting of the systems from the inside is possible. This leads to clogging and blockage of pipes, which reduces the productivity of the network as a whole.

The optimal thermal regime and its maintenance depends on the tightness of the systems. The reliability of the heating pipe prevents water from leaving the circuit and damaging nearby components and equipment. Strength characteristics, allowable temperature, and pressure are determined by the material of manufacture of the products.

The aesthetic appearance of heating pipes is very important if it is not possible to lay the system hidden

No less significant requirement for heating from pipes is its low noise. A properly organized system is the key to a calm and cozy atmosphere in the house. In addition, the pipe for organizing heating should have an aesthetic appearance, since it is not always possible to use a hidden gasket.

How to choose the right pipes for heating

When choosing a pipe for heating, several important aspects must be taken into account:

- type of pipeline laying;

- average water temperature and pressure inside the systems;

- heating configuration from pipes (smooth or flexible);

- the location of the pipeline.

The type of heating system largely determines the choice of products for its arrangement. Pipes for central heating, which are used in multi-storey buildings, must be so strong as to withstand a pressure of 16 atm. Products for individual systems used in cottages or private homes operate at a pressure of no more than 2-3 atmospheres.

Note! Pipe routing can be done externally or hidden in the walls, under the floor, inside the duct from wall panels or drywall.

Which heating pipe is better also depends on the ability and ease when it is necessary to repair batteries or other elements of the system. The network can be with gravity (natural) or forced circulation, which also affects the choice of the heating pipe.

The distance observed between communications depends on their material and diameter.

Types of pipes for heating

There are three basic groups of pipes for heating, which is better to use - depends on the specific situation:

- metal;

- plastic;

- metal-plastic.

Metal pipes for heating come in both copper and steel (black or stainless). For heating systems, galvanized pipes for heating are better suited. They have enough pros and cons, but the main advantage is that they are less prone to the influence of corrosion under the influence of water. Since zinc oxidizes faster, it protects the product. Galvanizing pipes for heating is carried out by diffusion or hot method.

The first option involves coating the steel pipe with zinc atoms. The temperature is about 400 ° C. Hot-dip galvanized pipes are obtained by immersing them directly in zinc in a liquid state. The temperature of this process is 450 ° C.

The organization of the heating system from pipes with natural circulation is best done using galvanized, stainless and steel products. Network operation is effective if the diameter of the communications is sufficiently large 25-50 mm and the necessary slopes and distances are observed.

Polypropylene pipes are often used in heating systems, but in networks with a high carrier temperature it is better to choose reinforced polypropylene

Plastic communications come in polypropylene and cross-linked polyethylene. Metal-plastic structures have layers of metal and polymeric materials interconnected in a special way. Polypropylene pipes can be laid even underground.

Black Steel Heating Pipes: Cons

They began to use the iron pipe for heating almost immediately after it entered the market. It has great mechanical strength, the ability to withstand significant pressure and temperature.

According to the manufacturing method, there are seamless (seamless) and suture. The second type is obtained by bending and welding sheet metal.

Note! Which heating pipe is better to choose depends on the situation, but seamless products are more durable and reliable.

A steel pipe for heating is not without drawbacks, including susceptibility to corrosion, heavy weight, insufficiently smooth inner surface, as well as the need for welding work during installation. The outer surface can be protected by a layer of paint and its updating must be done periodically.

It is impossible to protect the inner surface in this way, therefore it corrodes, especially if there is no water in the system or it drains from the pipe. The wall thickness, and, accordingly, the outer diameter of the steel pipes is greater than that of communications from other materials with a similar internal section.

The advantages of steel pipe

To avoid corrosion, it is better to use stainless steel pipes for heating, however, their cost is higher.

Steel pipes have been used in heating systems for a very long time and are most often found in apartment buildings

The main advantages of black steel products include:

- ability to withstand large mechanical loads and impacts;

- high temperature, significant pressure and water hammer do not have any effect;

- lack of need for compensation devices;

- excellent rigidity.

Even if the water temperature is maximum, the pipes have a small linear expansion. Such characteristics make it possible to determine steel products as the best for heating systems with natural or combined circulation.

They are good to use where it is difficult to adjust the water temperature and it is mandatory to observe the slopes of the heating pipes. An example of such systems can be complexes that operate from a solid fuel boiler or a furnace with a heat exchange part.

They should use such a pipe for heating, which is only able to withstand boiling of the coolant in an emergency.

The use of copper pipes for heating

Determining which pipes to choose for heating, you can focus on copper products. It should be remembered that they are oxidized in the presence of eddy currents and interaction with aluminum. Eddy currents appear when laying a heating pipe in a wall nearby with electrical wiring.

Copper pipes do their job perfectly even if there is an unstable (from negative values to +500 ° C) temperature of the flowing water.

Note! Due to the presence of smooth and corrosion-resistant internal walls, the material exhibits good wear resistance (it lasts up to 100 years).

A copper pipe for heating has a high throughput and thermal conductivity, it is tear resistant, withstands high pressures and is impermeable to oxygen. In addition, the material has a bactericidal effect. A system of copper products must be mounted in one of the following ways:

- low temperature;

- high temperature.

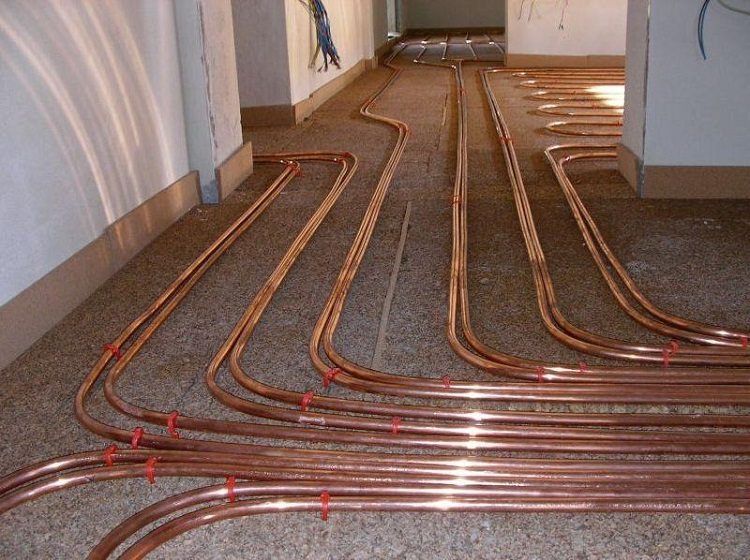

It is better to give preference to the first method, involving the use of flux. Copper pipes for underfloor heating ideal for laying laminate flooring. Their cost is slightly higher than that of analogues from other materials.

Features of metal products

Structurally, the pipes are plastic layers between which there is a metal foil. The polymer layers can be made of cross-linked polyethylene or other types of plastic. Such a structure manages to achieve very smooth internal and external surfaces.

One of the advantages of metal pipes is the ability to use them for installation of underfloor heating

When choosing heating pipes, it is worth taking into account what the temperature of the coolant should be and whether the selected pipes will withstand such heating. Metal-plastic communications are resistant to high rates - up to 95C. This explains their popularity. The lack of thermal linear expansion allows laying in the wall, in the floor under the laminate without expansion joints. Also, pipes made of metal-plastic for heating are applicable in systems with natural (forced) coolant circulation.

Today there are 3 types of heating under the laminate:

- infrared;

- electric;

- water.

It is important to know that laminate flooring is a cold coating. To make it comfortable to walk on, warm floor equipment is required. The laminate is laid on a special substrate that provides softening, sound insulation and moisture protection.

Use of polypropylene heat pipe

When deciding which pipe to use for heating, do not forget about polypropylene communications. Reinforced (aluminum or fiberglass) products are more suitable for the installation of such systems. Due to this, they hardly stretch if the temperature rises significantly. This property is important when placing heating pipes in the wall. The pros (and cons) of such placement is enough.

Reinforced pipes have higher strength and lower expansion coefficient than products without a reinforcing layer

Note! An unreinforced pipe can become so elongated when heated that it breaks down the fixtures that hold it.

When determining which heating pipes are better - reinforced with fiberglass or aluminum, it should be noted that both of them are suitable if the temperature of the coolant is up to +95 ° С.

Polypropylene pipes for heating are best used when building a network of a private house, where it is possible to regulate the heating of the coolant. If the water temperature rises, then the working pressure decreases.

The answer to the question of which pipes for heating can be laid underground, will also be polypropylene products. They are joined together by fittings.

XLPE pipes for heating

It is impossible to use transparent pipes for heating made of simple polyethylene. A cross-linked polyethylene product is suitable as thermal communication. Crosslinking technology allows you to get additional bonds between the molecules in the polymer structure.

As a result, the material has a high density, withstands significant pressure, the temperature of the coolant up to +90 ° C. From it, you can make underfloor heating underfloor heating and use it for laying underground. When heated, the polyethylene pipe for heating can be deformed to give it the necessary shape, which remains after cooling.

Lightweight construction does not create excessive load on the supporting elements. When choosing the right product, it is important to consider at what pressure the heating pipe will mainly be operated.

Declared by manufacturers, the communication period from cross-linked polyethylene is operational in the modes:

- 7 bar at 90 ° C;

- 11 bar at 70 ° C.

Between each other pipes made of polyethylene for heating are connected by press fittings using a special tool.

The principle of heating air from a gas boiler

One of the relatively new home heating systems is air heating, which is heated by a gas boiler. In this case, contact occurs by means of a special heating element. There is no high temperature and pressure in the heating pipes.

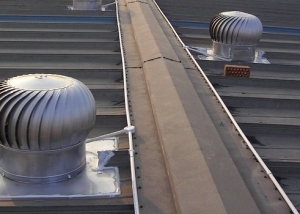

The principle of operation is as follows: with the help of gas equipment the metal is heated, which transfers heat to the air; Further, thanks to the fan, it enters the pipes, which need to drive the heated air into the room. In such a scheme, it is better to use metal thin-walled or flexible corrugated foil products.

Note! The air heating system must be calculated and installed during the construction phase of the building.

The placement of the heating pipe in the wall is often used, however, it is important to note its bulkiness and strong noise during use.

A separate issue is related to the circulation of warm air. Allocate:

- closed circulation;

- forward flow;

- recirculation with the ability to recharge air from outside (from the street).

The principle of the heating system by air does not imply the presence of high pressure in the network, therefore, pipes can be selected without special strength characteristics

The latter option is best suited, which by installing additional filters (electronic, mechanical or chemical), allows you to fill the room with purified air. The advantages of such a system are the organization of heating from pipes without batteries, an efficiency of more than 90%, efficiency and aesthetic appeal.

Procedure if a pipe breaks

In the event of a heat pipe accident, measures must be taken immediately. In order for the problems to be fixed correctly, a repair team or a plumber on duty is called. If the standard distance is maintained during installation, then independent access to the sections is provided.

There is not always time to wait for help if a heating pipe breaks. What to do in this case is determined by the possible threat of flooding the premises and the danger to humans. In such a situation, it is better to independently take any actions that limit the water distribution zone. It is important to remember that the temperature of the coolant is high enough.

If the pipe bursts, you can substitute any suitable container for collecting liquid under the stream so as not to damage the laminate or other floor covering. Although the laminate can deteriorate and with little exposure to hot water.It is also important to try to block the riser with valves. They are usually installed in the basement and in the apartment. The control valves of the heating system are often located on the supply line.

If the batteries break down or if a hot water pipe bursts, it is better to use thick rubber gloves when handling or removing damage.

When breaking a heating pipe, it is worth remembering that the temperature of the flowing water is very high

How to ensure a breakthrough sealing

If the heating pipe bursts and the arrival of the emergency service is delayed, then the water outlet must be temporarily sealed. To do this, you will need any piece of rubber (for example, from an old camera) and a screw clamp.

Regardless of which pipe is used for heating, in case of a breakthrough, you can do the following:

- Wrap the damaged area with several layers of rubber tape, and then fix the patch with clamps.

- In the absence of clamps, a thick wire or cord can be used.

- The last step in sealing a heat pipe or batteries is to wind several layers of high-density fabric and apply adhesive tape (such as adhesive tape).

Since water pressure actively affects the place where the pipe burst, such actions will help for a while to stop the spill of the coolant. When choosing pipes for heating, it is important to note that both stainless and galvanized products are very durable, but leaky threaded connections can leak.

You can solve the problem of leakage from the heating pipe before replacing the emergency section with a clamp

Some features of using smooth rigid and flexible pipes

Transparent pipes are used for viewing sections of pipelines; they are not resistant to high temperatures.

Note! The recommended distance from the batteries to protected electrical cables is more than 50 cm.

Flexible pipes for heating are often made of stainless steel. They are also used when installing underfloor heating under the laminate. Their service life is almost unlimited, and the geometry perfectly resists water hammer up to 60 atm. A water floor heating under the laminate can be assembled with a minimum number of joints in a very short time. The flexible heating pipe has a maximum operating temperature of 150 ° C and a pressure of 15 atm.

Sandwich pipes are often used to lay the trunk underground. They are assembled from smooth metal products with an insulated layer, which is protected from the outside with a rigid stainless or polymer shell.

The occurrence of such heating pipes underground can be different. The distance to the surface does not matter. If the shell is polymeric, then after laying the trench is buried by the ground. If the steel pipes are galvanized, special tunnels are required.

When organizing air heating through pipes, it is necessary to observe the distance from the grilles to furniture and household equipment.

A pipe for organizing space heating must meet all the requirements for reliability and safety of operation. A wide variety of products allows you to choose a suitable option that will ensure the thermal regime and satisfy all consumer conditions.