The main objective of the underfloor heating system is the distribution of thermal energy in the room by circulation through the hot water pipe, which is laid under the floor. The most common case is the supply of heated water to the pipes, but it is possible to use a solution of antifreeze or ethylene glycol. Copper pipes or metal pipes are used for underfloor heating.

Pipes made of metal-plastic are durable and flexible, so they are often used for arranging warm floors

Content

Floor heating system requirements

Underfloor water heating has a number of important advantages that allow you to heat the room evenly and with as little energy as possible. To achieve maximum effect, accurate selection of pipes for the entire installation area and a rational layout of their installation are necessary.

The selection of suitable pipes for a warm floor is associated with some of the requirements that apply to them:

- excellent heat dissipation;

- good durability;

- durability;

- low value of expansion coefficient;

- the smallest possible bending radius;

- environmental friendliness.

The amount of thermal energy entering the room depends on the heat transfer of the used pipe. The strength requirement is next in importance.

Note! The more durable the pipeline, the greater the working temperature and pressure it can withstand.

For a warm floor, pipes are laid in a concrete screed, which complicates the replacement or repair of parts if necessary. For this reason, the pipeline must remain operational for as long as possible.

Taking into account the expansion of pipes under the influence of high pressure and temperature is necessary to prevent damage to the flooring or concrete screed. The bending radius of products affects the minimization of the risk of damage to the pipeline when changing the direction of the elements. In the event of an accident or breakdown, the material of the pipes for the underfloor heating should not harm the environment and human health.

Underfloor heating structure

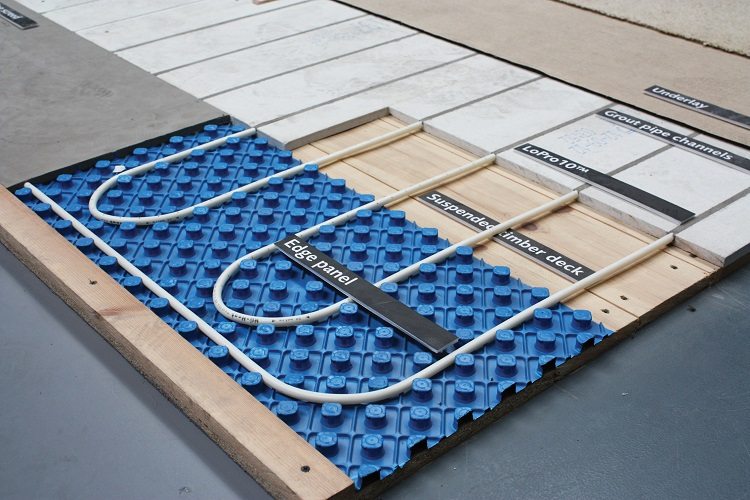

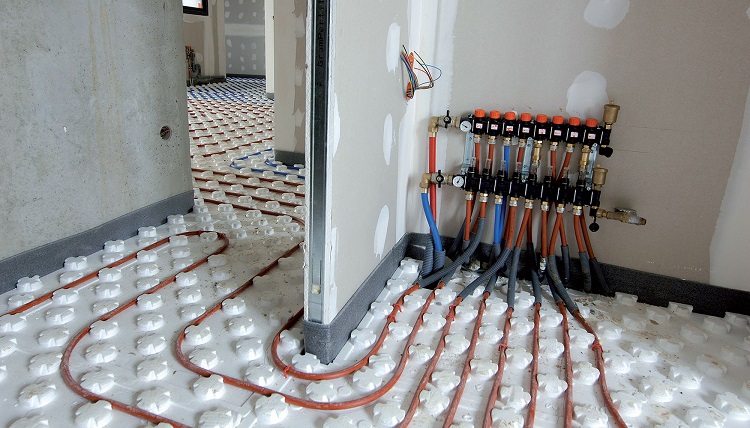

The warm floor has a multilayer structure. At the initial stage of arranging the system, it is leveled and a material with waterproofing properties is laid on the base. A damper tape is fixed along the walls adjacent to the floor. Further, the entire surface of the base is covered with insulating material and pipes are laid on it, through which water will be circulated. At the last stage, the carrier layer is poured and the floor covering is laid.

According to standards, the height difference in the room should not be more than 5 mm. If the floor is not leveled, then during operation there may appear problems with heat dissipation, airing of the system or increased hydraulic resistance.

The waterproofing layer protects the floor from condensation. To do this, you can use a plastic film. Damper tape is necessary to balance the expansion of the screed during heating. Thermal insulation will avoid heat loss.The final filling of the screed is performed with special building mixtures or mortars.

The recommended length of the laid pipes is 50-60 m and not more than 80-90 m. If these values are exceeded, a collector must be installed. In case the room contains 2 circuits, then the collector should have 2 outputs.

The use of plastic pipes for underfloor heating

Plastic pipes are the most common and affordable option for arranging a warm floor.

Important! These products have a layered structure and combine the best qualities of metal and polymer.

The inner layer plastic pipe made of polymer, which protects the pipeline from corrosion and scale and thereby prolongs the period of use. The intermediate layer is aluminum. It allows you to keep a good shape and withstand significant temperatures. The outer layer is also made of polymer, which protects aluminum from all kinds of environmental damage. Layers are connected with a special glue.

Metal-plastic pipes are convenient for a warm floor in that they are produced in bays of 25-50 m. Bays of a longer length can also be made to order. The optimal length of the pipe is 60-80 meters.

Laying and fastening of plastic pipes

For underfloor heating, plastic pipes can be laid with a snake (parallel method) or spirally. In the first embodiment, it is advisable to start laying from the side of windows and walls facing the outside of the room, since at the beginning of the pipeline there will be the highest temperature. This method is suitable for small areas.

Spiral laying involves a parallel arrangement of the supply and return pipes, which helps to compensate for the cooling of one of them by heating the other. This method is applicable for rooms with a large area.

When making a warm floor from metal-plastic pipes, the standard is the laying step of 10, 15 and 20 cm. Under certain conditions, it may increase to 25, 30 or 35 cm. There is a lot of heat loss near the windows and doors, which requires a step reduction of up to 15 cm .

The fastening of plastic pipes can be performed in several ways. A reinforcing mesh is placed on the heat-insulating layer, to which products are connected by wire. It also performs the role of marking the reinforcing element of the future screed. Typically, the pipe mounting pitch is 1 meter. The wire should not be pulled tight to prevent deformation due to the difference in thermal expansion of it and the pipe.

Important points of the device underfloor heating

Optimum are the diameters of metal-plastic pipes 16, 20 and 25 mm. Several factors influence the choice of sizes. A thicker pipe leads to raising the floor, increasing pressure in the riser. Installation of products must be carried out according to the scheme. For plastic pipe bending a spring of suitable diameter is used or pipe bender.

When laying pipes, it is important to prevent their deformation, therefore it is better to use a pipe bender for bending

All elements of the system are pre-checked for deformation. On the surface of the screed, pipes are fixed with plastic fasteners. When connected to the riser, the joints are well sealed. A test run of the underfloor heating is also required.

Note! If the system, being in test mode, is able to function for several days under pressure without leakage, then it is assembled efficiently.

After turning it off and cooling, the finish screed is laid. The need for the number of metal-plastic pipes depends on the area of the room, the nature of the flooring, the required climate. There is no need to heat zones in places where furniture, household appliances, a refrigerator, etc. are installed.Such a measure will reduce the cost of installing a warm floor.

Copper pipes for underfloor heating

A copper pipe for a warm floor is ideal for installing such a system, however, its cost is quite high. Such products have a significant margin of safety and durability, and together with excellent heat dissipation and bending radius, their use becomes the most suitable option.

Copper pipes are superior in strength and reliability to metal-plastic pipes, so this is the best option for a warm water floor

The copper floor heating system will effectively carry out its tasks for more than a dozen years. Copper processing is possible at any temperature. The pressure withstood by the pipes during operation is up to 200 atm., And the temperature is 100 ° C. Such indicators indicate a high resistance of the metal to all kinds of multiple temperature extremes. The copper pipe can be frozen and heated, which does not disable it.

An important characteristic of copper is its absolute harmlessness. Pipes possess bactericidal properties, are easily mounted due to their ductility and ease of bending.

You can lay copper pipes under any floor covering: laminate, tile, parquet and other materials.

Do-it-yourself device for a warm floor from copper pipes

If the basis for the underfloor heating system is a copper pipe, then you should know some of its nuances installation. The temperature of the water that will be supplied to the pipes is approximately 30-50 ° C. A heat pump, a low-temperature type boiler, a solar collector, and geothermal water can be used as a generator.

In the underfloor heating system, copper pipes are laid with a snake or spiral.

Note! The method of laying with a snake makes the heat distribution somewhat uneven, but the problem of cold sections of the room (near windows, doors) is solved.

A more even distribution of heat is provided by laying like a double worm. At the same time, ends should be located near the ends of pipes with a lower temperature, where the water is hot. This is the most rational way.

Plasticity of copper pipes and the absence of the need for additional components allows you to quickly lay. Currently, in some floor heating systems, copper pipes with a plastic coating are used, which allows to increase the tightness and reliability of the joints.

The installation of underfloor heating using metal-plastic or copper pipes requires certain knowledge, professional tools and equipment. Independent work must be carried out with extreme caution and compliance with all recommendations.