It is impossible to imagine a modern apartment without a durable and reliable heating system. In the domestic market there is a huge selection of boilers, various heat-generating devices and fittings in different price ranges. The most critical elements of the system are pipes. Their cost in the total cost estimate is about 20-27 percent. This factor determines the relevance of the question, which pipes are the best for heating in an apartment.

The choice of heating pipes is an important task, the solution of which is influenced by many factors

How to choose material for heating

When choosing a suitable option, the following aspects should be considered:

- laying method. The distribution of pipes for heating in an apartment can be both hidden and external. In the first case, the laying can be carried out in the walls, under the floor, inside the frame for wall panels or drywall.

- heating system diagram. From this point of view, it is necessary to take into account the type of room in which the heating pipes are laid. It can be either heated or unheated (for example, a basement);

- coolant temperature and operating pressure in the system. These indicators must be considered first.

- complexity of implementation. The heating scheme can be complex with additional configurations or simple, not requiring laborious installation work.

- ease of repair or replacement. In addition, the answer to the question which pipes are the best to use for heating an apartment largely depends on freedom of access to batteries.

The choice of pipes and the method of their connection largely depends on the type of network laying - hidden or open

In addition, the operational characteristics of the material and its installation requirements should be taken into account.

Metal pipes

New materials have not deprived metal pipe products of palm in heating systems.

Black metal. So, unlike plastic ones, steel pipes begin to melt at a very high temperature (+ 1500˚С). A weighty argument in favor of choosing such products is the lack of need for their additional fastening. However, disadvantages should be taken into account. One of them is that due to the large coefficient of thermal conductivity of steel, the delivery of coolant to radiators is associated with high heat losses.

Important! Hidden laying of steel pipes for heating is not recommended for an apartment, since this metal is subject to corrosion.

Stainless steel. In terms of the service life of heating pipes in an apartment, this is the best choice. The advantages of stainless steel should also include:

- non-susceptibility to electrochemical corrosion;

- ability to withstand high pressure;

- Attractive appearance throughout the entire service life.

Installation of a heating system from such pipes is quite simple both with external and hidden installation. The only but significant drawback is the high cost of stainless steel.

Copper. Pipes made of this metal are the embodiment of reliability and quality. On the installation of a heating system from copper pipes it takes a lot of time because it is necessary to use soldering method. This technical solution increases the service life of the structure, since the joint is not subject to thermal destruction.

But there is one caveat to keep in mind. Do not use aluminum radiators with copper pipes. Through the coolant, these metals enter into the electrolysis reaction.

The minus of copper pipes is the same as that of stainless pipes - high cost.

Plastic pipes

Due to the presence of technical characteristics that fully comply with the safety requirements and the strength of the heat supply system, the use of polymer pipes is more likely a regularity, and not an exception. Their most positive qualities include corrosion resistance. In addition, salt deposits and other sedimentary insoluble compounds do not accumulate on the inner surface of the plastic heating pipeline. Therefore, the throughput of the line throughout the entire life cycle always remains high.

Polypropylene pipes. A similar type of pipes for heating in an apartment is the most practical and cheapest option. In heating systems it is allowed to use exclusively reinforced polypropylene. Unreinforced analogues are characterized by high thermal elongation. It can not only bend, but even tear out the heating pipe from the point of attachment to the wall, which can lead to an emergency.

For a system with a low coolant temperature, polypropylene pipes without a reinforcing layer are quite suitable

For instance, pipeline installation was carried out at a temperature of + 20˚С. After that, he was connected to a heat supply system with water heated to + 90 ° C, which increased the temperature of the heating pipes in the apartment (15) by 70 ° C. As a result, the lengthening of one meter of unreinforced polypropylene pipeline will be 10.5 millimeters (the expansion coefficient of this material is equal).

Reinforcement is of the following types:

- aluminum reinforcement on the outside;

- internal aluminum reinforcement. Between the inner and outer polypropylene layers of equal thickness, there is metal;

- fiberglass inner reinforcement.

Helpful information! The formation of a multilayer structure is carried out using a special adhesive. Each manufacturer has its own manufacturing technology. It is kept under the strictest confidence.

It should be noted that today at the peak of sales there are products with external reinforcement. However, fiberglass reinforced pipes are best suited for organizing heating. Before starting welding, they need only to be very carefully cut off. There is no need to clean such pipes, since the plastic is integral with the reinforcing layer.

A conversation about which pipes are best for organizing heating in an apartment would be incomplete without mentioning one feature of polypropylene products: they soften from high temperature. Therefore, it is allowed to transport through them a coolant heated to no more than + 95 ° C.

Cross-linked polyethylene (PEX) pipes. If you still have not figured out which pipes are most suitable for heating systems, be aware: these products are also a good option.

Cross-linked polyethylene pipes are highly flexible, so they often become part of the heating system as a warm floor

Cross-linked polyethylene is a heat-resistant and durable material. At a working temperature of + 90 ° C, it is capable of briefly transporting a coolant heated to + 100 ° C. In addition, cross-linked polyethylene is resistant to negative temperatures (-20 ° C). When deciding to use PEX pipes, do not forget that their service life is 50 years.

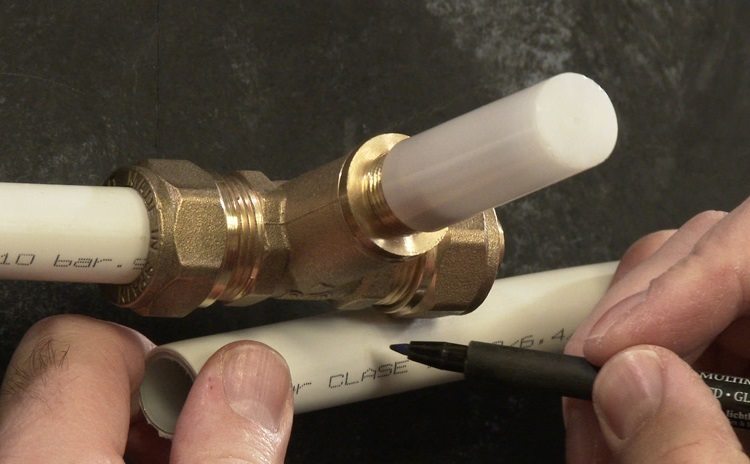

The system is assembled using special fittings. First, a sleeve or ring is put on the pipe.After that, the diameter of its end must be increased with a special device. At the final stage, the pipe is pulled onto the fitting fitting and a sleeve is placed on it.

Metal-plastic pipes. This is the last answer to the question of which pipes for heating is better to choose.

Of their advantages, we can distinguish:

- lightness and compactness;

- ability to withstand pressure up to 10 atmospheres and high long-term temperature (up to + 95˚С);

- good bandwidth. This is due to the fact that even with a small external section, the metal layer has a large internal diameter;

- two types can be used fittings: compression and press;

- for the installation of metal-plastic systems do not use special tools and expensive equipment. In this case, the heating pipes are fixed to the concrete wall using clamps or clips. However, such accessories must withstand the operating temperature of the heat supply system. To install some systems, double clips are used. With their help, two pipeline branches laid parallel to each other are fixed.

The method of joining metal-plastic pipes is simple, but very reliable, so they can be used in closed systems

How to choose a diameter

Having decided on the most suitable type of pipes for the heating system being implemented, it is necessary to correctly select their diameter. The hydrodynamics of the pipeline is a derivative, primarily from this characteristic.

Important! Moreover, the assertion that the efficiency of the system itself grows with an increase in the diameter of the pipes is erroneous. If it is unreasonably large, the pressure in the line will become minimal, due to which the circulation of the coolant will be disturbed.

This factor will lead to a change in temperature for the worse for residents of the housing: the room will not be sufficiently heated.

Too small a diameter of heating pipes is also fraught with inconvenience. In addition to reducing the life of the system, it will work very noisily: due to the small diameter, the pressure inside the pipeline branch can increase significantly.

Mistakes made during the development of the project are most often not amenable to selective correction: in this case, it may simply not be possible to completely dismantle the heating system and re-install it. Therefore, all stages of the design, including the choice of pipe diameter, must be carried out with all care.