Polypropylene pipes (PP) are used to replace obsolete or unusable elements of the heating system. Between themselves, PP pipes are most often welded, they also use the method of crimping pipes with couplings through special adapters - fittings. For fans to do something with their own hands, this is the best way. If it is impossible to weld the pipes, the gluing method is used.

Content

The main advantages of PP pipes

Among the advantages of this material are noted:

- do not react with the coolant and do not form oxides on the inner walls;

- correctly mounted system can be operated without fail for many years;

- easy to repair and upgrade;

- even a novice master will cope with the installation of a heating system from polypropylene pipes;

- the cost of PP pipes is lower than metal;

- installation does not require complex devices and components.

For laying heating pipes no special skills or abilities are needed.

Stages of preparatory work

Before starting work on arranging a heating system based on polypropylene pipes with your own hands, you need to draw up an accurate design plan.

Important! Not only the total length of the pipes of the heating system, but also its configuration is taken into account.

Be sure to take into account such moments:

- what type of connecting elements will be used to connect to the coolant circuit - welded PP elements, or combined, with the possibility of threaded joining with metal pipes;

- the presence of inaccessible places in which it will be impossible to solder the pipes. In this case, pre-docked elements of the future heating system are used;

- the type of system is determined: gravity circulation, or with forced convection of the coolant. For different systems, different installation rules apply;

- calculate the expected pressure in the circuit, and the temperature of the coolant. These data are necessary for the correct selection of the type of polypropylene pipe;

- Installation of heating from polypropylene pipes in cold rooms is not allowed, due to the risk of thermal deformation of the pipe.

In order to save financial resources, it is quite possible to install the heating system from PP pipes with your own hands. Minimum tool handling skills and accurate adherence to all assembly steps will help create a solid and reliable system.

Equipment used for installation

A soldering iron for polypropylene pipes - or an "iron", as it is sometimes called - is perfect for installing a heating system with your own hands from polypropylene pipes. When choosing a manual apparatus for welding PP pipes, it is necessary to take into account a number of nuances:

- An inexpensive pipe soldering iron is equipped with only the most common nozzles. As a rule, these are metal elements coated with a protective layer of Teflon.More expensive models are equipped with nozzles made of copper alloy;

- the wider the temperature range and the higher the power, the more convenient such an “iron” will be in use. High-quality installation of the heating system with polypropylene pipes is ensured by observing the temperature-time parameters of the soldering;

- a cheap soldering iron for PP pipes will not work for a long time;

- the shape of the soldering iron is important. A tube-shaped soldering iron for polypropylene pipes is more expensive than a hammer-shaped one. But it is much more convenient for them to make oncoming joints and to weld pipes with fittings with their own hands - corners in hard-to-reach places.

A rich set of professional equipment is not a reason to purchase it. On sale there are additional nozzles for a manual soldering iron for PP pipes.

The rules for installing heating from polypropylene pipes determine the exact correspondence of the diameter of the nozzle and the elements to be welded. Pipe-type soldering irons use nozzles of a different type, the standard “iron”, respectively, will not be able to work with nozzles from a tubular welding unit for soldering PP pipes.

Professional assembly teams use welding machines of a mechanical type. To combine the joints of large diameter pipes, which are difficult to hold in hands, use a special hydraulic drive. It makes it possible to work comfortably with polypropylene pipes with a diameter of more than 4 cm. Such an apparatus is characterized by a small coefficient of temperature error and high reliability. But installation of heating from polypropylene pipes by a mechanical apparatus will require certain skills from the operator.

Helpful advice! It is forbidden to use any type of welding equipment for polypropylene pipes in the absence of a reliable stand, which, as a rule, is included in the kit. Welding wet, wet or dirty from the inside of the PP pipe is unacceptable, in this case there can be no talk of the tightness of the seam.

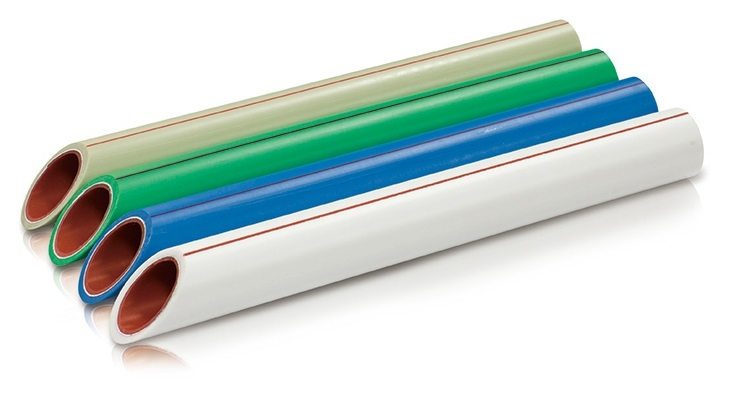

Types of polypropylene pipes

PP pipes are divided into two main types:

- reinforced;

- unreinforced.

The former are used where high pressure and temperature are expected. Such pipes are classified as “stabilized”, they have a minimum coefficient of thermal deformation.

Unreinforced pipes are used in technical systems for circulating fluids without heating. Such PP pipes are also used for cold water supply systems, which are also easy to install with your own hands.

Table 1

| Marking | Application area | Characteristics |

| PN10 | Low-pressure plumbing systems with minimum pressure | 10 atmospheres, 45 ° C |

| PN16 | Plumbing systems for cold water | 16 atmospheres, 60 ° C |

| PN20 | Hot water systems, not for heating systems | 20 atmospheres, 95 ° C |

| PN25 | Hot water systems, heating systems | 25 atmospheres, 95 ° C |

| Ppr | Heating, hot water. Unsuitable for arranging in-house cold water supply systems. | 25 atmospheres, 95 ° C |

The thickness of polypropylene pipes also matters. The value ranges from 1.9 to 18.4 mm, depending on the type and purpose of the pipe.

It's important to know! Pipes with the PPR index are used only for industrial purposes; it is not recommended to use them for drinking water supply by the manufacturer. The standard size of a polypropylene pipe of any diameter is 6 meters.

Specialized polypropylene pipes are used for the installation of “underfloor heating” systems. Such pipes are supplied for the underfloor heating in the bay, and most often they are not welded together, but are fastened at the joints with the heat carrier manifold by crimp couplings.

The underfloor heating circuit is a seamless system.Various types of floor heating are used. The geometry of any of the selected methods - "snail" or "along the contour" - determines the ability of the pipe to bend along the smallest radius. Excessive bending leads to irreversible deformation of the pipe.

The PP pipe for the warm floor is laid on the prepared base. Most often, this is a heat insulator in the form of a polyurethane foam layer, supplemented by heat-reflecting foil.

Good to know! Crimp couplings are securely fixed with special pliers; the kit also includes a template for checking the correct installation. Crimping pliers are quite expensive, it is more profitable to rent them during the final assembly and commissioning of the system.

Welding polypropylene pipes - basic rules

The initial stage includes the preparation of the tool that will be needed during installation. In addition to the direct soldering iron, special shears for cutting polypropylene pipes, which have been selected for the heating system. Such scissors consist of a concave lodgement, where the pipe is directly laid, and a guillotine knife with a step transmission unit.

Professional scissors for PP pipes are easy to distinguish from cheap fakes: they are massive, have a sliding spring and open wider than amateur ones. High-quality factory sharpening of the knife allows you to work with such scissors for a long time without much effort.

It is customary to cut the PP pipe exclusively at right angles, this will simplify the welding process in the future. The pipes reinforced with aluminum should be cleaned, this will ensure the technologically correct course of the processes of pipe jointing in the places of heating. For pipe stripping use a special device that is included with professional equipment.

Degrease the pipes with alcohols of the isobutyl or isopropyl groups, and nothing else. A non-fat-free surface will make itself felt during soldering - the seam will lose tightness.

Nozzles amateur, and especially professional welding equipment must be thoroughly cleaned. Sticky polypropylene fibers should be removed. The easiest way to do this is with your own hands, heating the nozzle and gently cleaning it with a dense cotton cloth or wooden sliver.

Heating time, weld width and cooling time

There is no linear dependence of the heating time of the PP pipes during welding of the elements of the heating system. Manufacturers of equipment supplement the complete set with an approximate table, which indicates the temperature regime of the welding machine for PP pipes and the time of fixing the tubes in the nozzle of the soldering iron.

It is necessary to try to warm the welded elements at the same time, this will ensure the best quality of the weld. If it is impossible to simultaneously heat up - for example, it is necessary to solder the pipe to the embedded element - use the separate soldering method - each element is heated separately, with the first element being heated being heated for a little longer than recommended in the table.

table 2

| Pipe diameter (millimeters) | Heating time (seconds) | Connection Time (seconds) | Cooling Time (minutes) | Welding Belt Width (millimeters) |

| 110 | 50 | 12 | 8 | 33 |

| 90 | 40 | 11 | 8 | 30 |

| 75 | 30 | 10 | 8 | 28 |

| 63 | 24 | 8 | 6 | 26 |

| 50 | 18 | 6 | 4 | 23 |

| 40 | 12 | 6 | 4 | 20 |

| 32 | 8 | 6 | 4 | 18 |

| 25 | 7 | 4 | 2 | 15 |

| 20 | 6 | 4 | 2 | 14 |

An ordinary building tape measure will help to measure the required length of the pipe, even a novice master can check the correctness of installation with the help of a level. Marks for cutting pipes are conveniently applied with a marker.

Helpful advice! Novice masters often mark the cut line without considering that part of the polypropylene pipe will be hidden in the connector or fitting. Make sure that the further installation is carried out by a more experienced master, if you find three couplings on a two-meter straight pipe section.

Due to the fact that PP pipes are inexpensive, it is possible to correct errors if they arise during the installation of heating with your own hands from polypropylene pipes. The accumulated experience will help you in the further arrangement of water supply and heating systems.

Installation of the heating system should be carried out in a ventilated room. Accuracy and care will help to avoid burns and injuries, and a careful calculation of components will save you from exceeding the original cost of the heating system.