HDPE pipe, the technical characteristics of which are at a high level, appeared on the plumbing market relatively recently. Polyethylene was invented only in the twentieth century, and began to use it in the manufacture of pipes even later. However, this material quickly gained popularity due to its quality and relatively low price. It is used for arranging communication systems of various types.

The characteristics and properties of pipes PND allow you to use from for laying pipelines for various purposes in the home and industry

Content

General characteristics of polyethylene as a material

Recently, polyethylene pipes have become increasingly popular in the field of repair and arrangement of various types of technical and sanitary communication systems. Polyethylene is a relatively new material in the field of arrangement and repair of pipelines. This is one of the first polymers used for such purposes. The popularity of such products is due to their many advantages compared to steel and cast iron counterparts.

Often the question arises, how is the name "pnd pipe" deciphered. These are the first letters of the name of the material that is used to manufacture the product - low pressure polyethylene.

In addition to the exact interpretation of the term "PND", the pipe is also called a product of high density polyethylene. This parameter is set by the manufacturing process. The functionality of the product and some operational characteristics depend on the density.

The pipe from low pressure polyethylene pnd is characterized by simplicity of design, reasonable price, versatility. The material itself is a thermoplastic ethylene polymer. This is the most famous plastic in the world. It is resistant to the negative effects of moisture, as well as corrosion (which can not be said about metal products). In addition, the details of pipelines made from it have a wider range of applications than, for example, high-pressure polyethylene pipes.

Polyethylene is the most famous type of plastic in the world, which is successfully used for pipe production.

Important! The characteristics of the product and its quality are tested at the factory and must necessarily meet the declared standards. Among them - the state standard, as well as ISO / TC SC4 No. 651.

Manufacturing process

In order to better understand the equipment, which is very important when choosing and buying products, it is worth remembering how the name is decrypted pnd or pvd pipe. It will not be superfluous to get acquainted with the features and main stages of the production process of such pipes.

The production process involves the use of thermoplastic polymers of different chemical composition.

Manufacturing technology includes several stages:

- granular raw materials are placed in the receiving hopper of a special apparatus - an extruder. From there, it moves into a cylinder equipped with heating elements;

- the material temperature for the future pipe is brought to the desired level, moving from less to hotter sections of the cylinder. Basically this compartment consists of three parts.In the first there is a supply of material, in the second - plasticization of the material for the future pipe pnd. What it is? This is the compression and melting of granules of raw materials. The third working zone is intended for the final homogenization and supply of plastic to the forming head - the die, which should have a fixed temperature regime. The quality of the resulting product largely depends on this;

- billet pipe polyethylene pnd takes on a form;

- it is placed in a special vacuum bath, where calibration is carried out;

- cooling, cutting and laying in bays of finished pipes p / e pnd is performed.

Note! The finished product is tested for strength. Since the technical characteristics of pipes from PND are regulated by certain standards, the products undergo special testing for strength and resistance to damage.

The initial stages of the production process (namely, the laying of raw materials into the extruder and bringing it to the desired temperature) are the same for different types of products - flexible, double-walled pvd and pvd pipes, thin and thick-walled. But shaping the material can be carried out under different temperatures and pressures.

Product advantages

Like any production product, this product has certain features that must be considered when choosing and installing equipment. To do this, you should familiarize yourself with its main properties.

Characteristics of pipes consists of both positive and negative properties.

Firstly, the material from which it is made is not subject to the negative effects of corrosion processes. Due to this, you do not need to worry about additional insulation of pipes from HDPE during underground installation or installation in a hidden way (inside a wall, or a specially equipped adit, for example).

In addition, you can use pipes made of low-pressure polyethylene for transporting and supplying water, without fear for its quality (whereas in the case of cast-iron and steel counterparts, rust and a metallic taste of water can get into the water supply).

Pipes are used for laying highways transporting drinking water, since polyethylene does not impair its quality

Secondly, polyethylene (PE) pipes have a fairly small weight (as for plumbing equipment), so transporting them is not so difficult and expensive. It also makes it easier that they are compactly packed in special bays at the factory.

Note! Another of the positive characteristics of the PND pipe is its long service life. The warranty term reaches 50 years. The reason is all the same resistance to the development of corrosion processes.

The useful properties of HDPE pipes include the fact that they are not afraid of moisture, aggressive organic and chemical compounds. In addition, they do not react with oily and fatty substances.

Cons and features

In addition to the significant advantages that make this product popular in the market of sanitary equipment, the polyethylene pipe has certain disadvantages. Technical characteristics do not allow the use of such a product for the arrangement of hot water supply systems and heating communications.

A pipe made of HDPE and HDPE is usually laid using additional insulating material (if this is a hidden installation in concrete, cement or a brick wall). This is due to the fact that a slight expansion of the pipe PND or PVD is possible under the influence of temperature.

And another drawback is that the service life and strength depends on the level of mobility of the soil in which the pipes are installed. This drawback is important to consider, since your site may simply not be suitable for installing such equipment on its territory. Otherwise installation of polyethylene pipes It will turn out for you an extra waste of time and finance. And if you use the pipeline to transport gas, then tragic consequences are possible.

Ultraviolet has a destructive effect on polyethylene, so pipes from this material are laid in a hidden way, for example, in a trench

Important! This material is susceptible to the negative effects of ultraviolet rays, so the installation of low-pressure polyethylene pipes should be carried out exclusively by a hidden method in a solid environment or soil. From the point of view of protection against mechanical damage, such a pipeline is significantly inferior to analogues of metal.

Classification of polyethylene sanitary equipment

Depending on the purpose, different types of pipes are distinguished:

- sewer. Such pressure equipment can withstand operating pressures from 5 to 20 atmospheres. These pipes are double-walled;

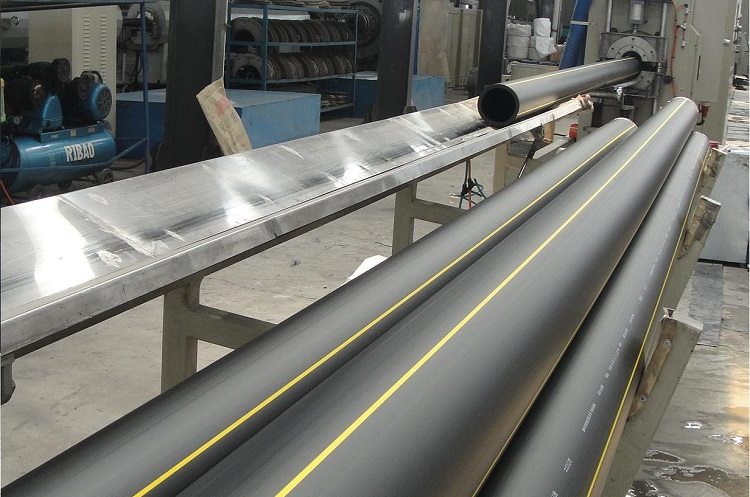

- water pipes pnd. They usually have a blue stripe along their entire length. Such equipment can withstand pressure from 5 to 15 atmospheres;

- gas piping pipes are communication elements for supplying gas from a gas holder to consumer appliances (fireplaces, boilers, heating devices, etc.);

- irrigation;

- technical;

- drainage pnd pipes.

In addition to this criterion, there is a classification by which pnd pipes are distributed relative to the pressure characteristic. So, there are low pressure, pressureless, high pressure and for rarefied air.

Additional information about the characteristics of the product is indicated directly on it in the form of marking polyethylene pipes. This information includes the minimum long-term strength index, GOST standard numbers, SDR coefficient, outer diameter, wall thickness, and manufacturer information.

Where and how are PND pipes used?

Polyethylene pipes are quite versatile. They are used for completely different purposes - both for communications of the underfloor heating, sewage, removal of soil from buildings and structures, and in cold water supply systems for residential buildings and irrigation of farmland, gas supply to residential and commercial buildings.

A method of using PND pipes to protect and isolate electrical wiring is also common. This method is very popular due to the low electrical conductivity of the material. For these purposes, mainly corrugated pipes with a probe are used - a thin wire adapted for greater ease of installation of communications.

Another useful property that has pipe pnd, these are good soundproofing characteristics, which makes a double-walled pipe made of polyethylene an ideal tool for sewage. In general, there are quite a few options that can be made from the pipe pnd. They are used even for arranging floor and wall heating, (due to the fact that they are flexible and light); however, for a warm floor, a cross-linked polyethylene pipe is more often used - it differs somewhat in properties. There are even special PND pipes for formwork.

In everyday life, water pipes are often made from pipes. Their walls are very smooth, so such systems are durable, do not require frequent diagnostics and repairs, sediment is not deposited on them, they are less likely to clog.

A popular variety of pipes PND - casing. What it is? This product is to protect the walls of wells with industrial or drinking water.

Choosing the right equipment

Technical characteristics of pnd pipes allow you to mount equipment in communication systems of any complexity, configuration and purpose. You can install them in any buildings - from commercial or industrial buildings to residential buildings.

The process of building communications begins with the choice of material. In our case, this is a plastic pipe (usually black), made of pnd.

Each pipe has its own purpose: for example, only those products that are marked with a yellow stripe are used for gas

We select the details of the future system, based on the most important requirements and conditions:

- seismic activity on the site. Not all systems can withstand underground deformations and shifts. Still, it is undesirable to lay pipes made of polyethylene in the soil with a high level of activity, especially if it is a gas pipeline or a system for supplying fuel or other aggressive chemicals. The pipe is not so rigid as metal, cracks may appear in it, which will cause an emergency;

- type of communication. Depending on this factor, distinguish certain types of polyethylene pipes. It is impossible to build a gas pipeline from those that are designed to supply cold water or corrugated pipes (red or black) that are produced to isolate and protect the electrical wiring;

- dimensions of the pipeline system. At the moment, the plumbing market can offer a very rich assortment of polyethylene pipes. They differ both in price and in technical features. Making the right choice is possible only considering both price and quality;

- installation type - “hidden” or not.

Different pipes have different characteristics. Some deteriorate under the influence of ultraviolet rays. They are perfect for installation in soil or a concrete wall, specially equipped adit. For the reception and withdrawal of effluents, water supply, such pnd pipes can be operated, but only if they are protected from light by cabinets, niches. However, if communications are conducted indoors or outdoors in an open space and are exposed to light, the best solution would be a double-walled pipe or pvd (usually red or black).

Features of installation and operation

Before you begin installing pipes, you need to find out what it is and how to do it correctly. It’s better to seek the help of specialists (in the case of gas equipment this is a prerequisite), and not build the system yourself.

Installation of a water supply system from piping can be done independently by using compression fittings

To begin with, it should be understood that the installation of pnd pipes is not a very complicated process, but it has certain nuances.

Depending on the type of polyethylene pipe, the description of the installation process will look completely different, since different equipment is used. So, there are three main methods: bell-shaped, compression-fitting and electric-welded joints.

Important! The throughput of the pipe and the purpose of the system are the main criteria when choosing a connection method.

When installing a home water supply or irrigation system (when small pipes are taken), they are most often used compression fittings. Connection sequence:

- The end face of the PND pipe is prepared, then an even cut is made.

- A union nut and a rubber ring are put on the workpiece for sealing.

- Then insert the product into the fitting and tighten the nut.

The welding method is very convenient, if only because the melting point of the pipe is relatively small, which means that it takes a little time, effort, energy to get a good connection. Butt welding is done by special by car and applicable for large diameter pipes. The description of the process can be divided into several stages that need to be performed in a clear sequence:

- center the workpiece;

- place the heater between the ends of the pipes;

- wait for the pipes to melt. After that, you can remove the device and connect the molten ends.

Process welding not too complicated and does not require special skills. With the strict implementation of the instructions, you can easily get a high-quality durable pipeline for any purpose.