Sandwich pipes - the optimal solution for the efficient operation of the chimney. They are a cylindrical structure consisting of a pair of metal pipes of different diameters, inserted one into another. In order to avoid excessive heating of the outer shell, a layer of non-combustible insulating material is installed between them. The interior of the presence of two protective layers almost completely protects against the appearance of condensation.

Content

How is a sandwich pipe for a chimney

Chimneys are mandatory elements for installation on all types of stoves and fireplaces. What are sandwich pipes for? They are intended for the removal of smoke and other unhealthy living creatures products generated in the combustion process into the atmosphere.

The design, which has, as a rule, a circular cross section, is composed of the following components:

- internal metal circuit resistant to high temperatures. It also provides other structural elements with protection against condensation. The diameter of the internal circuit connected to the stove (fireplace) is usually 200-280 mm, for a heating boiler with a capacity of less than 40 kW, a product with an internal section of 130-200 mm is selected;

- a high-strength external metal layer protecting the structure from destructive influences from the outside;

- an insulating layer of insulation, laid between the layers to prevent overheating of the outer surface.

Note! Layer thickness (from 30 mm) affects the temperature of the outer pipe. When a chimney is installed outside the building, then insulation is done more thoroughly.

If the sandwich pipe is supposed to be installed on the furnace, the equipment is equipped with additional components:

- knees. Provided with direction angles of 45º and 90º;

- cone. They provide free flow around precipitation;

- tee with angles of 45º and 87º;

- revision. Being installed on a stand (wall or floor) in the base of the chimney, it provides the ability to maintain its operability and control;

- spark arrestor;

- deflector;

- fungus;

- unloading platform;

- brackets;

- clamps.

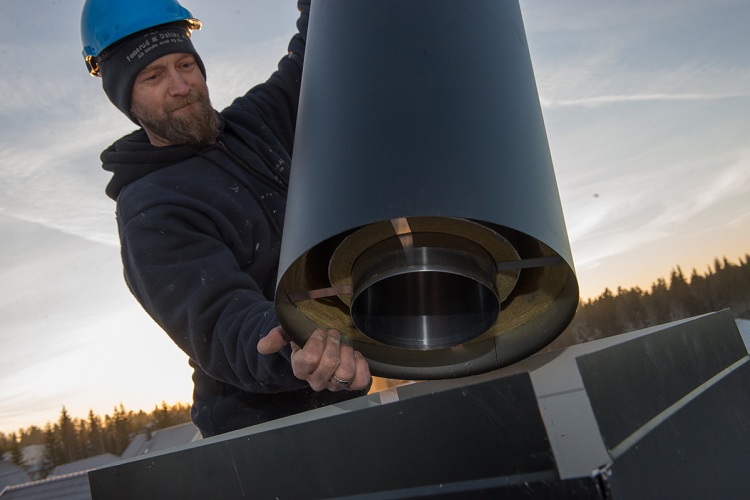

The basis of the chimney module of the "sandwich" type is two steel pipes inserted one into the other

How to choose a sandwich pipe and other components

When buying individual elements for arranging a chimney, it is advisable to obtain a factory certificate containing technical specifications, names of boilers to which connection is allowed, types of fuel used and warranty periods for operation. Manufacturers of quality products always attach the necessary fastenings to the modular elements and deliver them in reliable packaging.

For the manufacture of sandwich pipes, materials are used that are resistant to corrosion. Combustion products entering the chimney contain a certain amount of chemically active substances - sulfur, sulfuric and hydrochloric acids. Under their influence, ordinary steel will quickly oxidize and burn out. Therefore, a highly alloyed stainless steel with a thickness of at least 0.7 mm is used - for the inner pipe and half a millimeter - for the outer contour. The inner loop must:

- maintain a temperature of 850º C for a long time;

- cope with a short-term one and a half times the temperature rise.

AISI 321 steel, which, like its Russian counterparts, contains a significant proportion of molybdenum, is considered to be the highest quality, differing:

- maximum resistance to acids;

- high heat resistance;

- ability to withstand centuries of use.

The most common is the AISI 430 steel product, which can withstand a short-term temperature jump of up to 900º C. It is designed for ten to fifteen years of use, but has a great advantage in terms of cost.

Good to know! If there is no marking on the pipe, the quality of the steel can be checked by applying a magnet to which steel with alloying additives should not react. Its matte or polished surface will not lose its luster over time.

More economical is the use of enameled pipes, less heat-resistant and resistant to acids. They are considered quite suitable for connection to:

- heating boilers;

- heating columns;

- stoves and fireplaces that work as usual.

An economical option is also the use of combined sandwich pipes, in which the inner pipe is made of stainless steel, and the outer one is galvanized or enameled.

For gas-fired boilers, galvanized inner pipes will fit, and the outer seam can be obtained by skating. For solid fuel boilers, an internal stainless steel pipe with a laser welded seam is needed. It is mandatory to take into account the diameter of the boiler pipe on which the sandwich pipe is worn.

The thermal insulation material is selected so that it does not deform at a temperature of 650 degrees. To ensure fire safety and protect the chimney from freezing and the appearance of condensate, it is desirable to install its thickness at least five centimeters. For warming it is supposed to use:

- basalt wool. The most economical offer, but the temperature should not rise above 600º C;

- vermiculite. Lightweight material with good thermal insulation properties, persisting in the range from -250º C to 1150º C;

- ceramic wool. The fibers of the material have been given special deformation, thermal and chemical resistance. At a higher cost, the advantage of ceramic wool is the ability to withstand temperatures up to 1260º C.

Pipes differ in the inner layer, the maximum working temperature of the finished chimney depends on this

Advantages and disadvantages of sandwich pipes

The use of sandwich pipes in the arrangement of chimneys allows you to:

- dispense with the foundation necessary for the construction of a brick or ceramic;

- perform all necessary work, regardless of the time of year;

- mount the chimney from the boiler, regardless of the fuel used;

- give the design any configuration and not worry because of the complexity;

- to achieve the highest possible fire safety;

- simple and convenient to carry out installation, due to the presence of a large number of connecting elements, as high quality as pipes;

- effectively reduce heat loss;

- Avoid spoilage due to condensation

- to exclude the influence of natural conditions on the inside of the structure;

- get rid of the occurrence of crashing noise and noise;

- limited to cleaning soot, without resorting to constant repairs and replacement of elements;

- get an environmentally friendly design;

- create an aesthetically attractive look.

The disadvantages include:

- decrease in tightness due to sections reacting to temperature differences by narrowing and expansion;

- relatively high cost of structural components;

- the ability to operate for no more than fifteen years, which is significantly less than conventional chimneys. Although the designs made of high-quality materials can last several times longer.

The sandwich chimney is aesthetically pleasing and does not require additional decorative decoration

Features of installation of insulated sandwich pipes

When installing a chimney with a sandwich, take into account a number of nuances that ensure the duration and safety of its operation. First of all, you need to achieve traction stability:

- the chimney must reach a height of at least five meters;

- the pipe head must be raised to a height of more than half a meter above the surface of a flat roof (a half meter distance to the ridge must be maintained on a pitched roof);

- It is desirable to install the structure strictly vertically. Allowed inclined sections (45º);

- Connection to the heating unit is carried out at an angle of 2º. The length of this almost horizontal section is up to one meter, but it can be doubled at a chimney height in excess of five meters;

It's important to know! The length of horizontal sections in the structure should not exceed two meters - for a stove or fireplace, three meters - for a heating boiler.

Having solved the problem with traction, do not forget about some other features:

- it is forbidden to connect a chimney made of stainless steel to coal-fired heating units;

- the channel structure should not pass near flammable materials;

- placement of galvanized products in living rooms and in rooms with a high level of humidity is unacceptable;

- with a chimney height exceeding one and a half meters, it is advisable to fix it more reliably, using tension clamps or erecting a support mast;

- the joint sealant must withstand a working temperature of 1000º;

- each section of the pipe joint with the chimney construction elements is strengthened with a clamp;

- structural strength is supported by the installation of wall brackets with an interval of two meters along the length of the channel;

- the tee is installed on a support platform or console;

- any structural elements containing combustible materials are isolated at the points of contact with the pipe or indented for them;

- the section coming from the heating unit must not be insulated;

- having a large part of the structure indoors, they achieve a decrease in the temperature difference, therefore, the heating efficiency increases.

After completing the installation and getting started, remember that it is unsafe:

- use the chimney to dry clothes or household items;

- the use of construction waste as fuel, objects whose coating contains paints or varnishes, etc.

There should be no flammable materials around the chimney, and the place where the pipe exits through the ceiling is equipped with a metal apron

Installation of a chimney inside the building

The process of attaching a sandwich pipe begins by connecting the coupling to the chimney hole of the heating unit. By installing an enlarged adapter, an increase in heat transfer and a decrease in the heating of the chimney are achieved. Next, the horizontal section of the pipe or tee is fixed. Then, having installed a tee, its lower part is closed with a very necessary plug, removing which it will be possible to periodically remove soot.

The passage through the roof is carried out in the following sequence:

- A hole is being made, which, most likely, will need to be further strengthened.

- Installing a roof groove will allow you to easily equip a roof passage.Roof cutting should be adjacent to the base of the roof, the edges of the structure start, located under the ridge (trim).

- The inside is equipped with a roofing sheet metal.

- To give the structure complete tightness, an adjustable apron is mounted on the roof groove.

- Equipping the hole for the passage of the vertical pipe, install the adapter. A straight pipe is passed into the prepared hole from the attic or from the street. Docking modules when passing through the ceiling is prohibited. The next work proceeds after completion of the insulation between the pipe and the ceiling with fire-resistant materials. In the future, the plot is plastered and painted over.

- Turning to work in the attic and roof, the assembly is carried out by lowering the pipes from above and connecting with the lower modules in order to avoid condensate entering the channel.

Important! The upper part of the structure is crowned with a head so that birds do not make a nest and small debris and precipitation do not fall into the pipe.

Installation of a chimney outside the building

They resort to the installation of the chimney outside the premises in order to avoid cluttering the internal space and, if it is impossible to make a hole in the roof (floor level). Installation begins as well as when installing the chimney inside the house. After installing the starting fitting, attach a horizontal pipe to it or resort to using a bend with the desired angle of rotation.

In the wall you will need to make a technical hole through which the chimney section will be passed. This operation is performed as follows:

- A small area for arranging a technical hole is carefully disassembled.

- In order to ensure the reliability of the fastening of the chimney section, the space around it is additionally strengthened. To do this, you can use wooden blocks or buy special items in a hardware store.

- Having strengthened the hole for the transition, they begin to install the bracket, additionally equipped with runners, to facilitate the passage of the pipe.

- A connection is made to the tee bracket (adapter). This element will be connected on both sides of the channel pipe.

- The wall around the passage of the chimney is covered with plywood sheet. Asbestos sheet covered with a strip of galvanized metal is fastened to the plywood layer.

- Providing for the possibility of corrosion, fasteners are opened with varnish used for a metal surface.

- Passing a section of the chimney through the hole, the remaining free space is filled with a layer of heat-insulating material with a thickness of about 150 mm.

- The pipe end brought to the outside of the building is completed with a tee with a blank plug in the lower part. If necessary, a support console is brought under the outside section.

- Anticipating the beginning of the vertical assembly of the chimney channel, brackets are installed on the wall surface, the distance between which does not exceed two meters. How to make installation, what fasteners to choose for conducting decide, based on what constitutes a covering or material of construction. High-altitude work will require the use of a ladder, possibly a crane. As the structure is installed, its stability is supported by putting on special hoops, which are parts of the brackets.

- When the structure is raised above the roof to a height of one and a half meters, it is worthwhile to take care of installing additional stretch marks to provide greater stability.

- Installation is completed by fixing the head.

The design of the sandwich pipe is arranged in such a way that the lower part of the inner contour is inserted “through smoke”, excluding its penetration into the surrounding space. The upper part was made so that the subsequent connection of the pipes occurred "by condensate", preventing it from falling into the insulation layer. Drainage of condensate occurs without penetration into the structure of the sandwich pipe.

Installation of a sandwich pipe on its own seems to be quite possible. In this case, one should keep in mind the inadmissibility of errors and neglect of fire safety. Hermetically assembled and firmly installed construction made of correctly selected materials with timely and simple maintenance is guaranteed to last at least a decade and a half.