In order for the ventilation system to work optimally, serious demands are placed on the air ducts. The industry produces many types of such products. But the most effective are spiral-wound ducts. This is due to the fact that the resistance of the air transported through the system in this case is minimal. Thanks to this, the cost of acquiring the main components of the ventilation system — the supply unit, fan, is reduced.

What is a spiral-wound duct

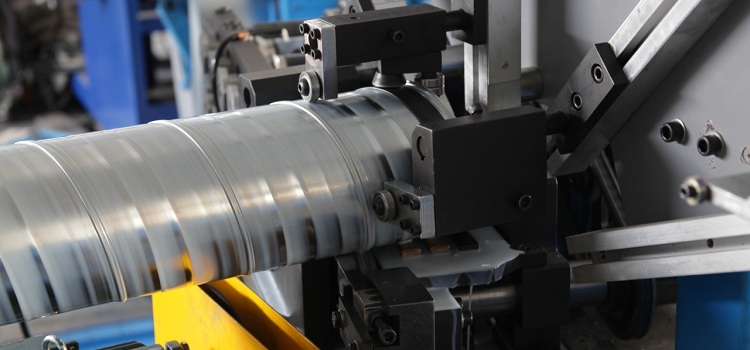

This product is a coiled steel tape. The edges are fastened by a lock. Being located along the entire length of the ducts, it ensures their reliability. In addition, this technological solution creates the ability to produce products with a length of 12 meters. This is the main difference and, at the same time, an advantage in comparison with straight-seam type ventilation ducts.

The spiral-wound metal duct is characterized by a robust construction, but is difficult to manufacture. The seam located outside the product is treated with sealant. Thus, the absence of gaps prevents the reduction in the volume of transported air mass.

Benefits. Features of production and operation

Spiral ducts also have the following advantages:

- quick installation of ventilation;

- there is no turbulence in the air flow. For this reason, the noise level is reduced;

- air is transported evenly at high speed. This is facilitated by the great pressure achieved due to the absence of gaps;

- significant indicator of energy saving;

- low cost service;

- attractive appearance.

Good to know! When forming a closed chain of rings of winding ducts, the thickness of the tape plays a special role. If the value of this parameter varies in the range of 1-2 mm, welding machines are used. Sheets up to 1 millimeter thick are joined according to the seam principle.

Flexible materials can be rotated and deployed many times. However, this possibility does not apply to semi-flexible spiral products. Here, the conduct of such manipulations must be minimized.

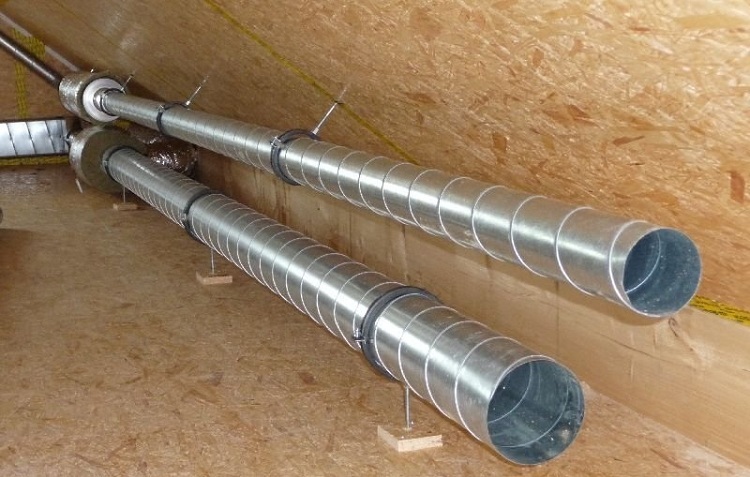

The above factors have led to the fact that spiral ducts are very common. Their shape creates space for maneuverability. In other words, product-specific flexibility allows for easy installation of ventilation ducts in a room.

However, spiral-wound ventilation ducts have one small drawback. This is an increased aerodynamic drag. To reduce costs and improve performance, experts recommend creating ventilation ducts with originally fully deployed spiral ducts. At the same time, the step of the holders that secure the pipe should be such that its sag does not exceed 40 mm / m.When it is necessary to rotate the pipe, its radius should be within 0.55 of the cross section of the ventilation duct. If these rules are followed, then the installation of the structure will be easy and harmonious.