To mount a plastic pipeline, essentially the pipes themselves and the fittings are used. Fittings - devices used to fasten pipes to each other. The main thing is to buy suitable fittings before installation. Plastic pipes must only be connected with reliable parts; check fittings for defects before purchase.

Content

Types of fittings for plastic pipes

All plastic pipes with fittings available to consumers are divided into the following types:

- polypropylene materials;

- polyvinyl chloride materials;

- metal-plastic materials;

- polyethylene.

The use of a variety of fittings provides the ability to mount the system, creating a reliable connection, even initially in inaccessible and difficult places.

In fact, plastic pipe fittings mean a variety of parts used to secure both pipes and hoses. Depending on the need, there are various forms and types.

All fittings for plastic pipes are divided into two main types:

- fittings with threaded connection (threaded);

- fittings used to connect straight sections of plastic pipes to each other.

Threaded fittings are divided among themselves into non-separable and collapsible. All of them require sealing the threads with linen or special tape when screwing onto the pipe.

Already in appearance (the term “style” can be indicated in the marking), all fittings are grouped into the following categories:

- adapters;

- drives and couplings;

- crosspieces and tees for plastic pipes;

- compensators;

- corners;

- control valves;

- American women

- corks with plugs for plastic pipes.

All these elements come in different sizes, so picking up the right one is very easy.

Most popular fittings: differences and features

Most often with connecting pipes made of plastic several types of similar products are used. Each of them has design features, advantages and disadvantages.

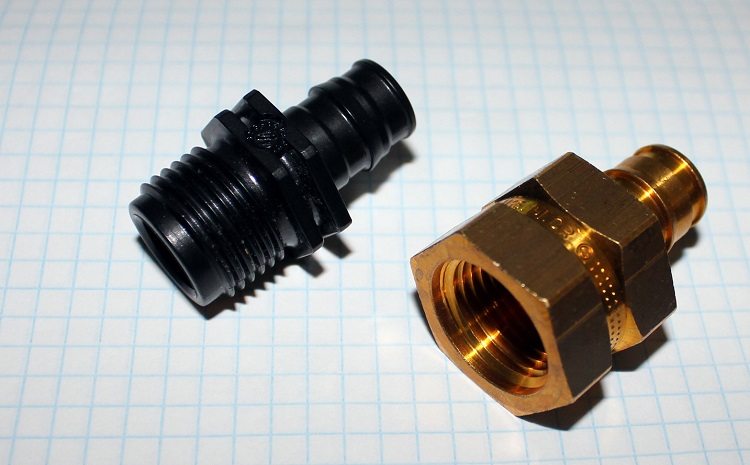

American

It is a one-piece, non-separable design, which is designed to connect various plumbing parts to the water supply and to connect a plastic pipe with a metal one. The part is sealed due to a special cone with either silicone or rubber O-ring.

American women are divided into two types:

- direct;

- angular.

The use of corner fittings will allow the corner joint of a plastic pipe to be performed without undue stress on the plastic pipe and plumbing fixture. There are two types of American women - with external thread, and internal thread.

Advice! The use of American women with different threads will allow for the installation of the pipeline, without involving additional adapters.

Stubs

The plugs are represented by dead ends, which are connected to the pipe by soldering or thread. Instead of sealing the hole, use a plug.

The purpose of the plugs for plastic and metal-plastic pipes is to protect the pipes from the penetration of foreign objects and dirt into the system. Plugs for plastic pipes can be mounted both with pipes and other fittings. The advantage of using plugs will allow for future pipeline upgrades. The plug is dismantled, and a new pipe section is attached instead. Depending on need, plugs can be soldered and screwed.

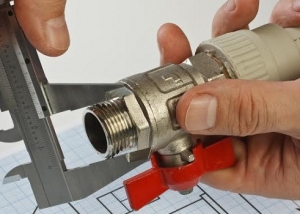

Stop valves

This category of products includes valves and taps. Shut-off valves are divided into two main types: manual valves and thermostatic valves.

The fittings also differ in the type of their body, and it happens:

- polymer;

- metal with thread.

When mounting the former, it is soldered into the system, while the latter, on the one hand, are always equipped with an American, which allows you to mount the valve immediately, without disassembling the entire system).

Advice! Stop valves designed for cold water should not be installed in the piping for gas or hot water.

The main distinguishing feature of the crane is a high degree of tightness, which determines the area of use.

Faucets are used when mounting a plastic pipe, which is then used to supply cold / hot water or gas. They are relevant when using hoses for supplying water.

Crosses and tees

Plastic sanitary tees are connecting elements that play an important role in the installation of any pipeline. Plastic tees for hoses are used to create branches or to connect several hoses, pipes. Depending on the needs, tees with straight lines (90 degrees) or sharp corners (35-40 degrees) are used.

Advice! Do not use the connecting tees for other purposes. Otherwise, with a strong internal water pressure, the entire system is deformed and disintegrates.

Crosses with tees for plastic pipes are:

- transitional - the neck and through holes of the tee have different diameters;

- Equal passage - the neck and the through holes of the tee have the same holes.

The tees fittings are connected to the pipes by soldering or threading. Transitional tees are also common, allowing you to switch from one type of connection to another (from thread to solder, and vice versa).

Swivel joints

Swivel joints or angles allow you to rotate the pipe when mounting. Corners are joined with pipes both by soldering, and by tightening with a nut. The dimension of the angles is diverse, but the most common angles are 90 degrees.

Couplings

Couplings are designed to create high-quality connections of absolutely identical parts in diameter.

The following types of couplings are distinguished:

- plastic pipe couplings used for plastic pipe soldering and made of the same material with pipes;

- couplings used to mount elements that are made of various materials (when, on the one hand, it is necessary to use soldering, on the other - a nut);

- couplings that are used to transfer from rigid pipe sections to corrugated sections (actively used when installing a sewer pipeline);

- couplings - adapters.

The joint for plastic pipes is relevant when connecting long sections or when joining several pieces.

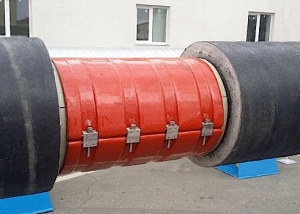

Supports and bends

Bypass fittings include connecting elements that can significantly simplify the installation of the sanitary pipeline at the intersection of several routes or to resolve some structural obstacles - when it is necessary to lay the pipeline near an already installed system.

Plastic supports are designed for rigid fastening of pipes. Only relevant if it is prescribed by the instructions when installing the heating system and the pipeline for supplying hot water. The use of supports will reliably secure the entire structure at pre-thought out points.

Installation of plastic fittings

Before you purchase parts for mounting a plastic pipeline, you must firstly have a ready-made plan. You should also know in what conditions the pipeline is to be operated - the choice of the length of plastic pipes depends on this. The number of fittings and their varieties depend on the plan and length of the pipes.

Advice! When mounting, various types of fittings are always used. Buy spare parts - two, three more than originally planned.

Before mounting with a fitting, PVC pipes must be cut with a hacksaw for metal (with a fine-toothed blade). This hacksaw after itself in the place of cutting does not leave protruding pieces of plastic.

After the pipe is cut off, the cut point is always processed. Burrs and some rough spots are removed. This procedure is necessary in order to fit the fitting more tightly during installation. The surface is cleaned so that during operation of the pipeline at the junction there are no blockages and leaks. Cleaning is carried out on a dry and fat-free surface. It must be repeated when mounting the plug.

If voids have formed in the place where the fittings and pipes are connected, they must be treated with glue using a brush. Do not forget about plugs - they will prevent dust from entering the pipeline. Observing all the prescribed rules for installing the pipeline, you will get a system that will last for many decades. And the use of plastic pipe fittings will allow a new connection of the pipeline if an unexpected obstacle arises.